Inter-axle differential lockout – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 68

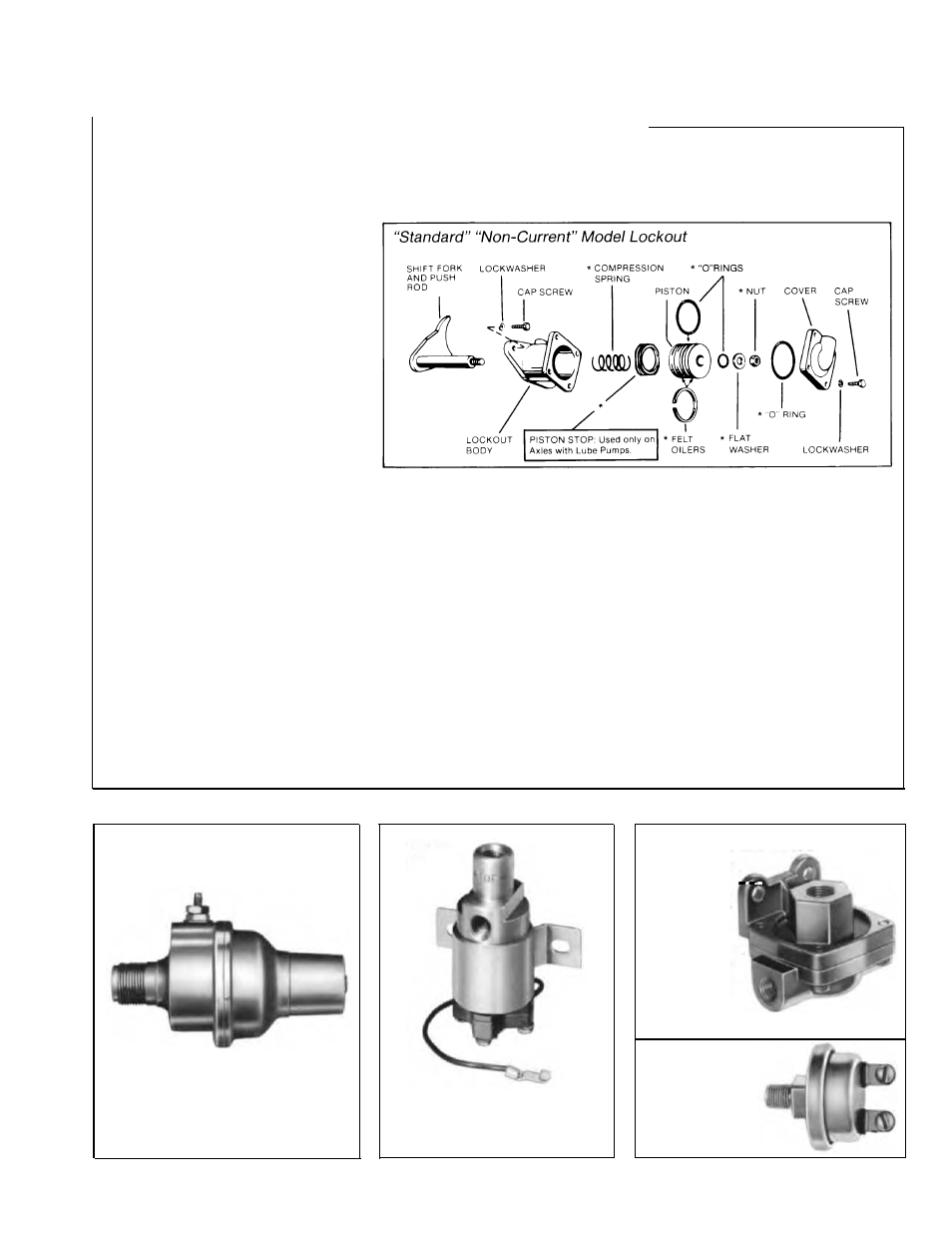

Inter-Axle Differential Lockout

(with Interlock Control Valve)

(straight-air type)

Lockout Cylinder

Disassemble Cylinder.

1.

Remove cap screws, lockwash-

ers, cover assembly and "O" ring,

2.

Remove hex-nut piston and

"O" rings.

3.

Remove body cap screws and

lockwashers, then remove body

and piston as an assembly.

Assemble Cylinder.

1.

Apply gasket compound to

mounting surface on power divider

cover.

2.

Install lockout body. Secure

with cap screws and lockwashers.

Torque cap screws to 48-56 ft-lbs.

(65-76 Nm).

NOTE:

Before installation, soak

piston felt oilers in SAE 30 engine

oil and lubricate "O" rings with a

high-viscosity silicone oil or barium

grease "O" ring lubricant.

3.

Install felt oilers and "O" ring on

piston.

Axles with Lube Pump:

Before

installing piston, place piston stop

at base of lockout body.

4.

Install compression spring over

shift fork push rod. Install piston in

body. Install "O" ring over push rod

and in piston. Install hex-nut piston

and tighten to 20-26 ft-lbs. (27-35

N«m). Install "O" ring on piston.

5.

Install "O" ring in lockout body cover. Install cover assembly and

secure with cap screws and lockwashers. Torque cap screws to

96-108 IN-LBS. (10-12 N«m).

6.

Adjust interlock control valve.

Interlock Control Valve

Repair and Replacement.

Replace faulty valve as an assembly,

Remove Valve.

1.

Loosen locknut and unscrew valve body from cylinder cover.

Install and Adjust Valve.

NOTE:

If button is not assembled to valve stem, install as follows: Insert

valve stem to full depth of the button. Lock in place with set screw. Torque

set screw to 6 IN-LBS. (0.7 Nm).

1.

With button assembled to valve, install locknut and Iockwasher on

valve body. With lockout cylinder exhausted, screw the valve assembly

into the lockout cylinder cover until the valve is seated on hex-nut piston.

2.

To adjust, unscrew control valve until the valve air-delivery port is

aligned with the lockout cylinder air-inlet port.

NOTE: Do not unscrew

valve more than 360

o

.

Lock the valve in place with locknut. Torque locknut to 35 IN-LBS.

(3.9 Nm).

Speedometer Adapter

The speedometer adapters are

lubricated and sealed for life of

the unit. No maintenance is

required. Replace a faulty unit.

Solenoid

Valve

Replace solenoid valve as an

assembly. The valve should

not be serviced.

Quick Release Valve

ã

If quick release

valve fails to

operate prop-

erly, it may be

repaired as

follows: Dis-

assemble valve.

Inspect valve

body, valve seat

and spring (if

used) for evi-

dence of faulty operation.

Replace

faulty parts, then reassemble valve.

,. .. .

Pressure

Switch

Replace pressure

switch as an assembly.

69