Gearing and torque distribution, Dual range gearing, Torque distribution in high range – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 6

Gearing and Torque Distribution

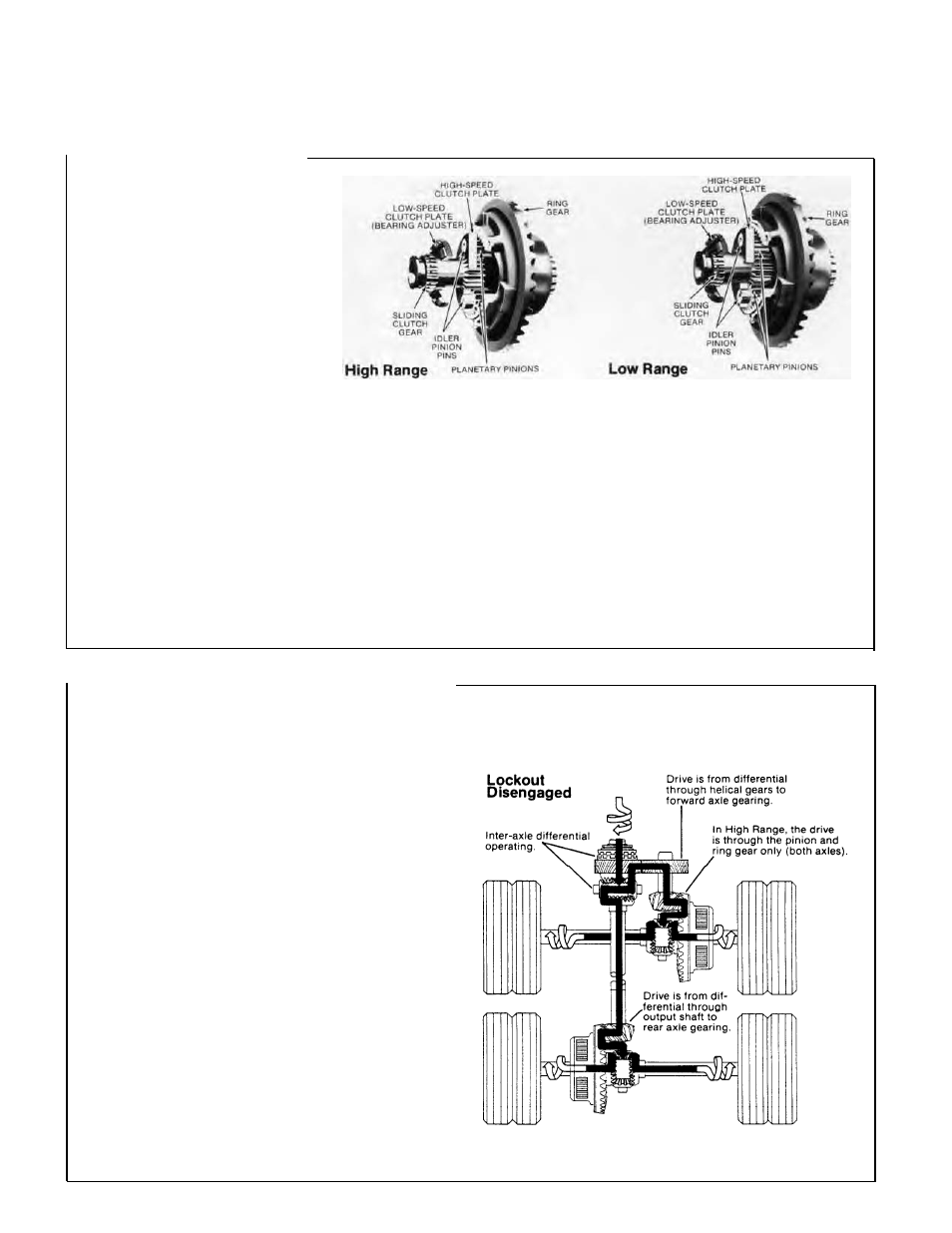

Dual Range Gearing

The gearing for each axle is a

combination of a spiral bevel ring

gear and pinion and a planetary

unit.

First reduction (High Range) is

provided by the spiral bevel

gearing.

Second reduction (Low Range) is

through the planetary gearing.

Four planetary idler pinions are

confined within the ring gear and

mesh with the ring gear internal

teeth. The planetary gears rotate

around a sliding clutch gear.

Each axle is equipped with a shift

unit, which operates the sliding

clutch gear to provide means for

selecting the axle range. Range

selection is accomplished through

the movement of the sliding clutch

gear in and out of engagement

with low and high-speed clutch

plates.

The sliding clutch gear is locked

into the high-speed clutch plate

and rotates as part of the differen-

tial assembly. The planetary pin-

ions are stationary and the axle

uses only the single reduction of

the ring gear and pinion. Power

flow is through the drive pinion,

ring gear, differential unit and axle

shafts.

The sliding clutch gear is shifted

into engagement with the low-

speed clutch plate (an integral

part of the bearing adjuster). The

sliding clutch is held stationary and

the planetary pinions are forced to

rotate around it. Power flow is now

through drive pinion, ring gear,

planetary gearing, differential unit

and axle shafts. The axle uses two

reductions to multiply torque. The

planetary unit adds approximately

36¡/0 more reduction to the primary

gear set. Torque is multiplied on

an equivalent basis.

Torque Distribution in High Range

Torque (power flow) from the vehicle driveline is

transmitted to the input shaft and the inter-axle

differential spider. At this point, the differential

distributes torque equally to both sides.

For the forward axle, torque is transmitted from

the helical-side gear to the pinion helical gear,

drive pinion, ring gear, wheel differential and axle

shafts.

For the rear axle, torque is transmitted from the

output shaft side gear, through the output shaft,

inter-axle driveline, to the drive pinion, ring gear,

wheel differential and axle shafts.

INPUT

TORQUE

Torque is transmitted to both axles through inter-axle

differential action.

6