Power divider overhaul, Adjust input shaft end play, Measure and adjust end play – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 42

Power Divider Overhaul

Adjust Input Shaft End Play

NOTE:

After power divider overhaul and installation in power divider,

check and adjust input shaft end play.

Correct end play when new parts are used in overhaul is 0.003î to

0.007î, with reused parts 0.01 3ñ to 0.01 7ñ. Refer to page 19 for other

variations.

Measure and Adjust End Play

IMPORTANT:

In September 1988, Spicer added a Spring and a Thrust

Button between the input and output shafts. End play tolerances are the

same for axles with or without this Spring and Button. However, end play

measurement procedure is different than described below. Refer to Service

Bulletin Supplement at back of this manual for procedure variances.

1.

Remove input shaft nut, fiat washer and yoke. Remove input bearing

cover cap screws and lockwashers. Remove bearing cover (and shim

pack if installed).

2.

Reinstall bearing cover without shims. Hold in position with hand

pressure and measure clearance between power divider cover and

bearing cover, using a feeler gauge.

3.

The bearing cover clearance measured in Step 2 plus 0.005" will

equal shim pack thickness required for desired end play (rebuild with

new parts). Add 0.015" to shim pack for rebuild with used parts.

4.

Install shim pack and bearing cover. Install cap screws and lock-

washers. Torque screws to 75-85 ft-lbs. (101-115 Nm).

5.

Install yoke, flat washer and nut. Tighten nut snugly. Tap end of

input shaft lightly to seat bearings.

6.

Check input shaft end play with dial indicator positioned at yoke

end of input shaft. Move input shaft axially and measure end play. If

end play is correct, seal shim pack to prevent lube leakage then torque

input shaft nut and cover cap screws (see chart).

7.

If end play is incorrect, change shim pack size, as follows:

Add shims to increase end play.

Example: Desired end play (New Parts) . . . . . . . . . . . . . . 0.003" to 0.007"

Measured end play (Step 6) . . . . . . . . . . . . . . . 0.001" - 0.001"

Add shims to provide desired end play . . . . . 0.002" to 0.006"

Remove shims to decrease end play.

Example: Measured end play (Step 6) . . . . . . . . . . . . . . . 0.015" - 0.015"

Desired end play (New Parts) . . . . . . . . . . . . . . 0.003" to 0.007"

Remove shims to provide desired end play . . 0.012" to 0.008"

8.

To add or remove shims, remove input shaft nut, flat washer and yoke.

Remove cap screws, lockwashers and bearing cover. Add or remove

shims as required.

9.

Install bearing cover, cap screws and lockwashers. Install yoke, flat

washer and nut. Seal shim pack to prevent lube leakage then torque

input shaft nut and cover cap screws (see chart).

I

Torque Chart

Input Shaft Nut

Ft-lbs.

1-5/8-18

780-960

*M42 X 1.5

840-1020

Bearing Cover Cap Screw

1/2-13

75-85

Nm

1057-1301

1140-1383

101-115

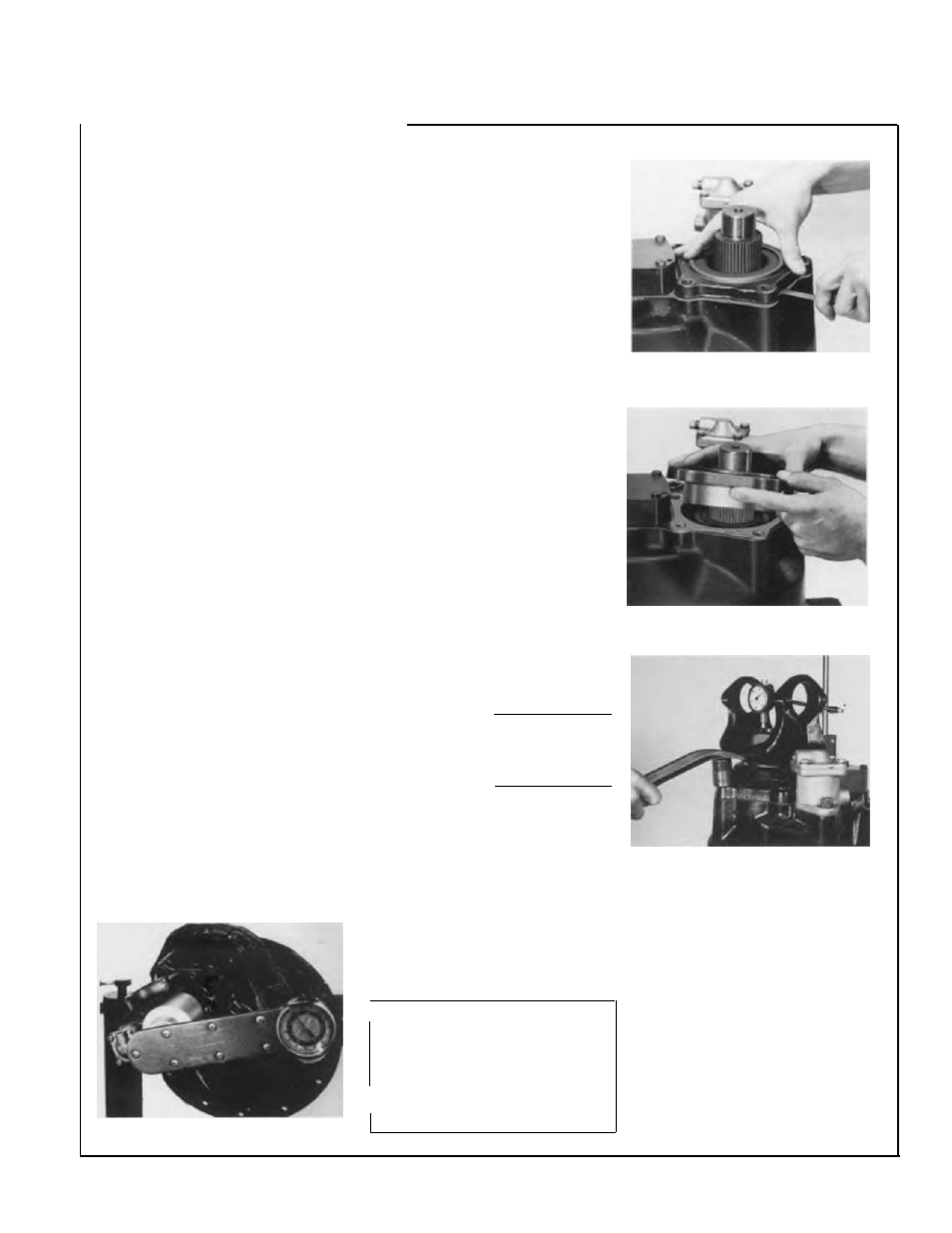

Tightening Yoke Nut.

(Grade 5)

Measuring Bearing Cover

Clearance.

Installing Bearing Cover and

Shim Pack.

Measuring End Play with Dial

Indicator.

NOTE:

If difficulty is experienced

in achieving correct torque on the

input yoke nut, torque the nut with

truck on the ground and axle shafts

installed.

ñMetric Nut used on Axles produced after 7/1 /95

42