Differential carrier overhaul, Forward axle - install pinion, Forward axle - install helical gear – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 54

.

Differential Carrier Overhaul

I

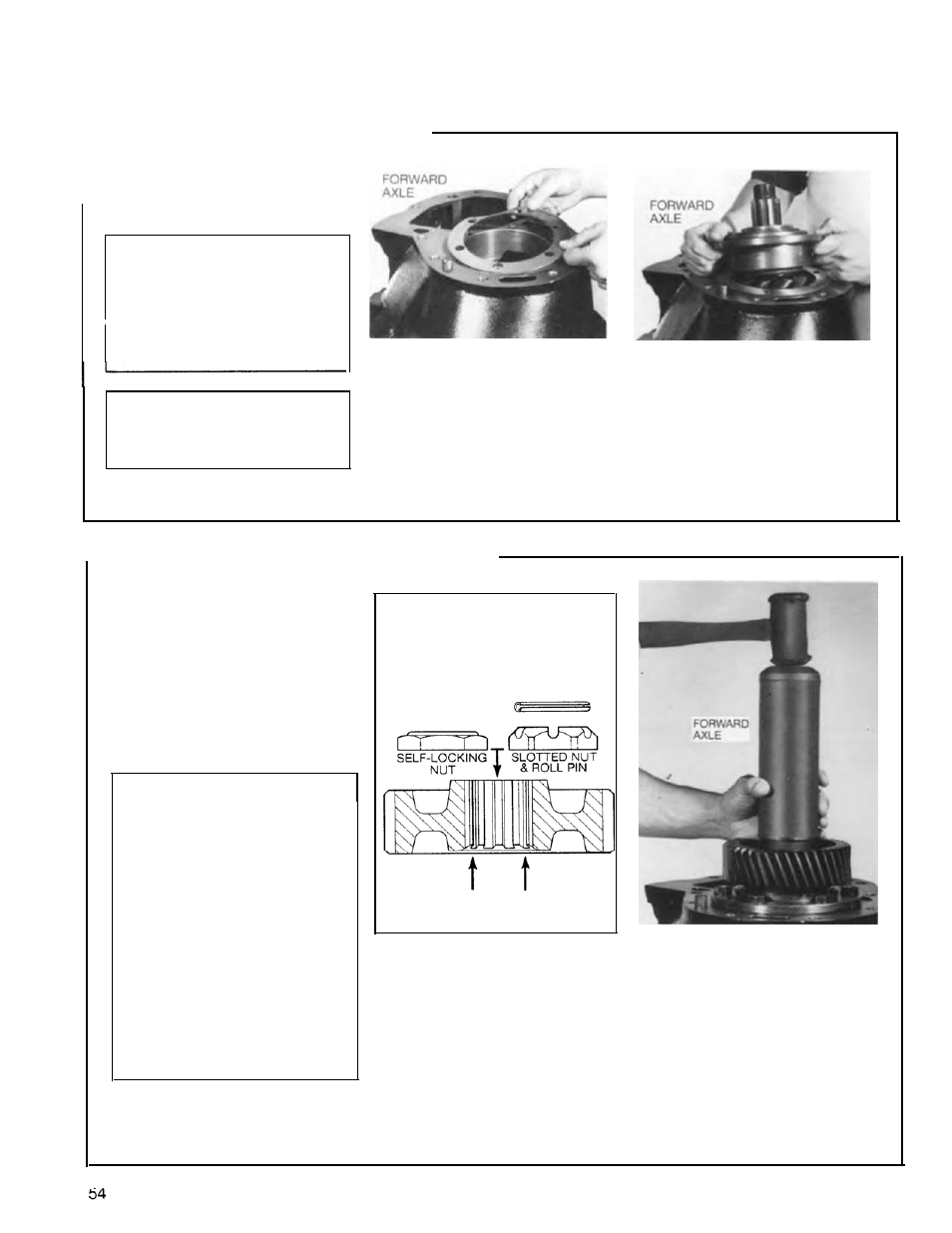

Forward Axle -

Install Pinion

I

1. Output Shaft Side Gear Bearing

Cup.

If removed, press bearing

cup in carrier.

Torque Chart

Bearing Cage Cap Screw

Size

Ft-lbs.

N.m

I

9/16-12

155-175

210-237

(Grade 8)

Nominal Shim Pack

In.

mm

0.024

0.609

2.

Place shim pack on carrier,

making certain that holes in shims

are aligned with carrier holes.

NOTE:

If gear set is to be reused,

install same quantity and size of

shims removed during disassem-

bly. When installing a new gear

set, use nominal shim pack

(see chart).

3.

Install drive pinion assembly.

Install bearing cage cap screws

and lockwashers. Torque cap

screws (see chart).

NOTE:

The forward axle pinion is

equipped with a helical gear. For

easier disassembly during carrier

adjustment procedure, use a dum-

my yoke (if available) in place of

helical gear.

Forward Axle - Install Helical Gear

1. Install helical gear on pinion,

positioned as shown in the illustra-

tion. Install self-locking nut or

slotted nut. Torque nut properly

(see chart), using a suitable fixture

to hold helical gear.

NOTE: On axles equipped with

slotted nut and roll pin, do not

install roll pin until carrier

adjustments are completed.

Torque Chart

Pinion SELF-LOCKING NUT

Size

Ft-lbs.

Nm

(D340, 380(P), 400-P)

1-1/2-18

560-700

759-949

(D341 ,381 (P), 401-P, 402(P), 451-P)

1-518-18

780-960

1057-1301

(D341 , 402(P), 451(P)

produced after 7-1-95

M42

X

1.5 840-1020

1140-1383

Pinion SLOTTED NUT

& ROLL

PIN

(D341, 381(P), 401-P, 402(P), 451-P)

1-518-18

840*

1139*

Pinion Helical Gear

Mounting Position

NOTE:

See Torque Chart for

Pinion Nut Variations

POSITION LARGE CHAMFER

TOWARD BEARING CONE

Installing Pinion Helical Gear.

*IMPORTANT:

Torque to 840 ft-lbs.

(1139 Nm), then continue tighten-

ing nut to align slot with the nearest

hole in pinion shank. Install roll

pin.

I