Install differential carrier assembly – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 31

Install Differential Carrier Assembly

IMPORTANT:

D341, 381(P), 401-P, 402(P), 451-P models do NOT use an output shaft Rear Bearing Retaining Washer

WARNING:

WHEN INSTALLING DIFFERENTIAL CARRIER ASSEMBLY, IT IS IMPORTANT TO

FOLLOW CORRECT PROCEDURES TO ASSURE USEFUL LIFE. FAILURE TO CORRECTLY INSTALL

REAR BEARING AND RETAINING WASHER COULD RESULT IN PREMATURE AXLE FAILURE.

IMPORTANT:

Before installing carrier assembly, inspect and thoroughly clean interior of axle housing.

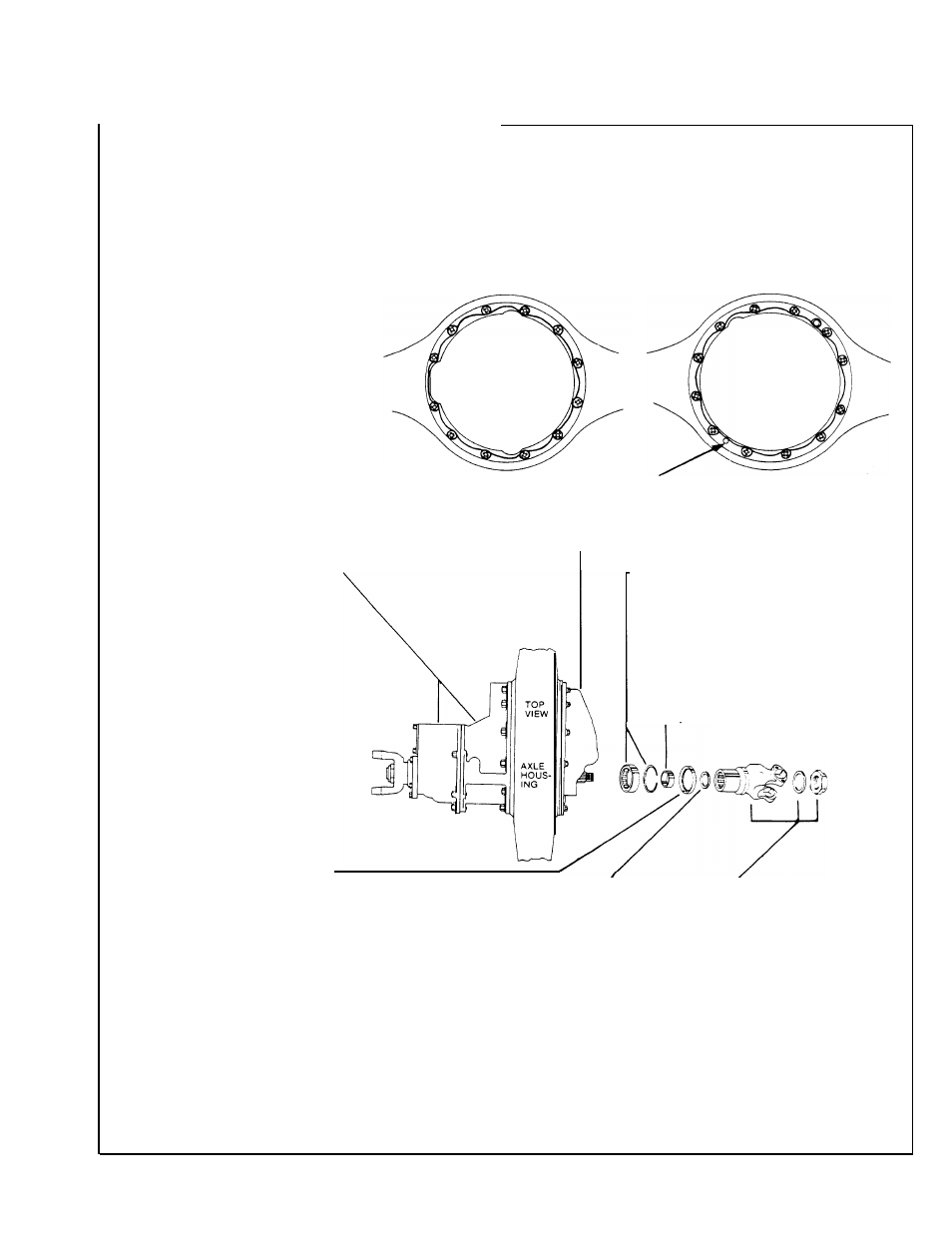

NOTE: Use silicone rubber

SILICONE GASKET COMPOUND

SILICONE GASKET COMPOUND

gasket compound on axle housing

PATTERN. DIFFERENTIAL CARRIER

PATTERN. HOUSING COVER

mating surface as shown in the

MATING SURFACE.

MATING SURFACE.

illustrations. Compound will set in

20 minutes. Install carrier and axle

housing cover before compound

sets or reapply.

Location

of hole in

(Follow procedure in numerical sequence.)

rear cover.

1.

Apply silicone gasket compound.

2.

Axle Housing Cover and Output Shaft Bearing Parts.

If removed,

Install differential carrier assembly

install cover and fasten with nuts, cap screws and lockwashers. Tighten

in axle housing. Install nuts and “

to correct torque. If removed

lockwashers. Tighten to correct

torque.

Reference torque chart

page 76.

5.

Install a new output shaft’

seal in the axle housing cover *

until flush with chamfer in bore.

Lubricate the seal inner

diameter to prevent damage

during yoke installation.

8.

Install axle shafts, and stud

nuts (if used, also install lock-

washers and taper dowels).

9.

Connect main and inter-axle

drivelines.

10.

Fill axle with correct lubricant

(see Lubrication Section).

install bearing parts (see steps 3 through 6).

-3.

Install output shaft rear bearing.

Tap the outer race (with a sleeve or

drift) until it is seated firmly in the

machined pocket of the cover.

Secure with snap ring.

4.

Lubricate and install the rear bear-

ing sleeve on the output shaft. Make

certain it fits snugly against the

shoulder at the forward edge of the

\

shaft splines.

6.

Slide the rear bearing retaining

washer over the splines of the

outer shaft until it seats flush

against the output shaft bearing.

IMPORTANT:

*D341, 381 (P),

401-P, 402(P), 451-P models do

NOT use an output shaft Rear

Bearing Retaining Washer.

11.

Connect differential lockout

air line.

12.

Dual Range Axle only — Install

shift unit, nuts and lockwashers.

Torque nuts to 55-61 ft.-lbs. (74-82

N.m). Connect air line.

7.

Install output yoke, flat washer

and self-locking nut. Tighten to

correct torque. Ref. chart on page

26, 76.

NOTE:

Flat washer not used with

metric threaded nuts.

IMPORTANT: When axle has been

disassembled or housing, gears,

axle shafts or wheel equipment

replaced, check axle assembly for

proper differential action before

operating vehicle. Wheels must

rotate freely and independently.

*IMPORTANT See page 15

for service information on Seals, Yokes & Slingers.

31