Press tool – FEC DSP1500 (SAN3) User Manual

Page 31

PAGE 3-7

enFORCE

Operation Manual

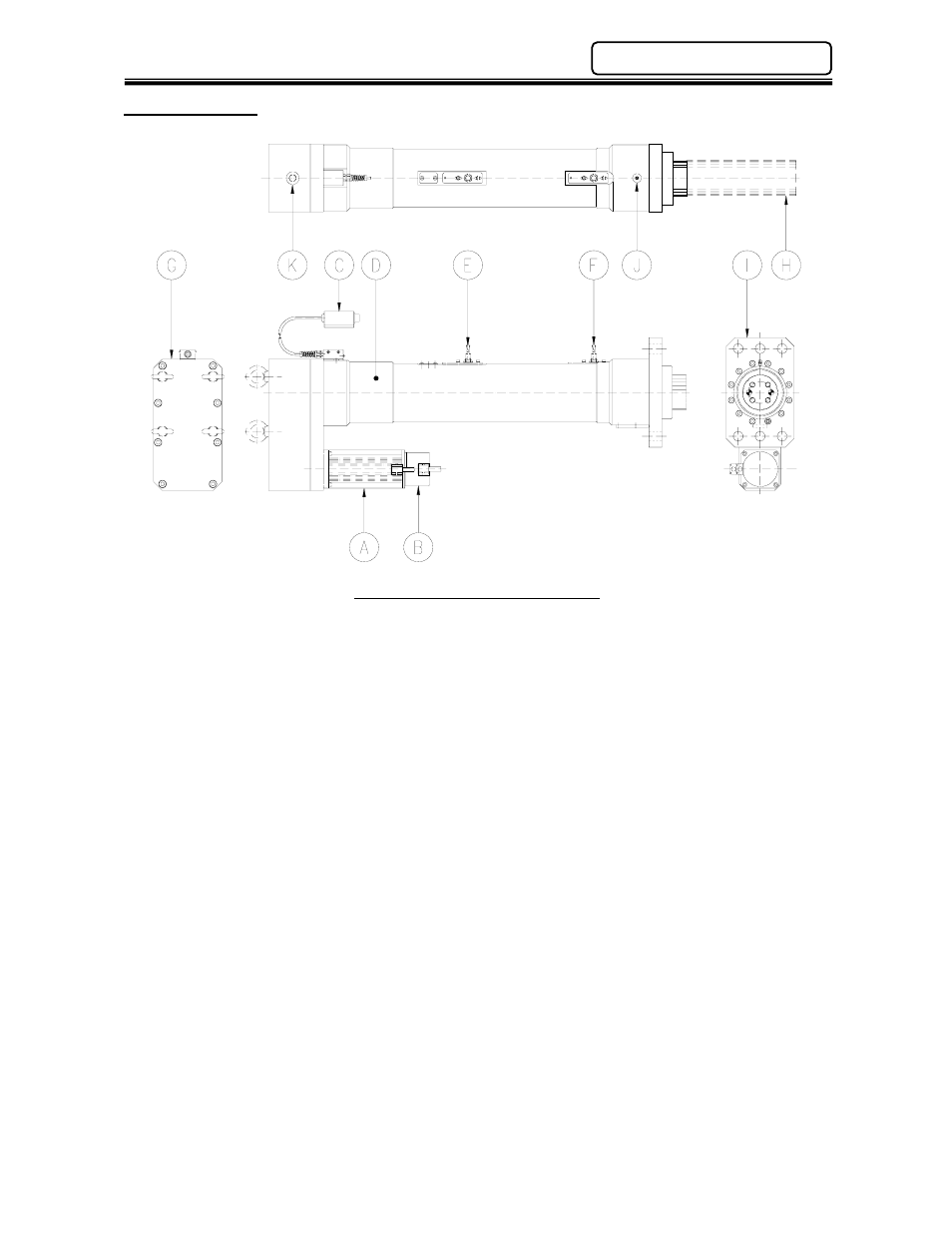

3.3 Press Tool

Drawing Shown For Reference Only

A) MOTOR:

Totally enclosed DC permanent magnet motor

Refer to Chapter 2 for available motor sizes

B) RESOLVER:

Provides feedback for speed regulation to servo amplifier

Provides distance monitoring capability to press operation

C) PRE-AMPLIFIER:

Amplifies load transducer signal.

Houses “I.D. chip” used to verify tool functionality

D) LOAD CELL:

Precision strain gage load transducer

Provides

press

force

feedback

to

servo

amplifier

E) HOME POSITION PROXIMITY:

Counter-clockwise (return) limit sensor

F) ADVANCED PROXIMITY:

Clockwise (advance) limit sensor

G) GEAR HOUSING:

Durable gear transmission

H)

SPLINE:

Ball

screw

driven

press

ram

I) MOUNTING FLANGE:

See Chapter 2 for size and hole pattern

J) GREASE FITTING:

Spline lubrication point.

K)

LUBE ACCESS POINT:

Gear lubrication point (availability and location dependant

on

press

size)

Chapter 3: System Description