San unit specifications – FEC DSP1500 (SAN3) User Manual

Page 17

PAGE 2-3

enFORCE

Operation Manual

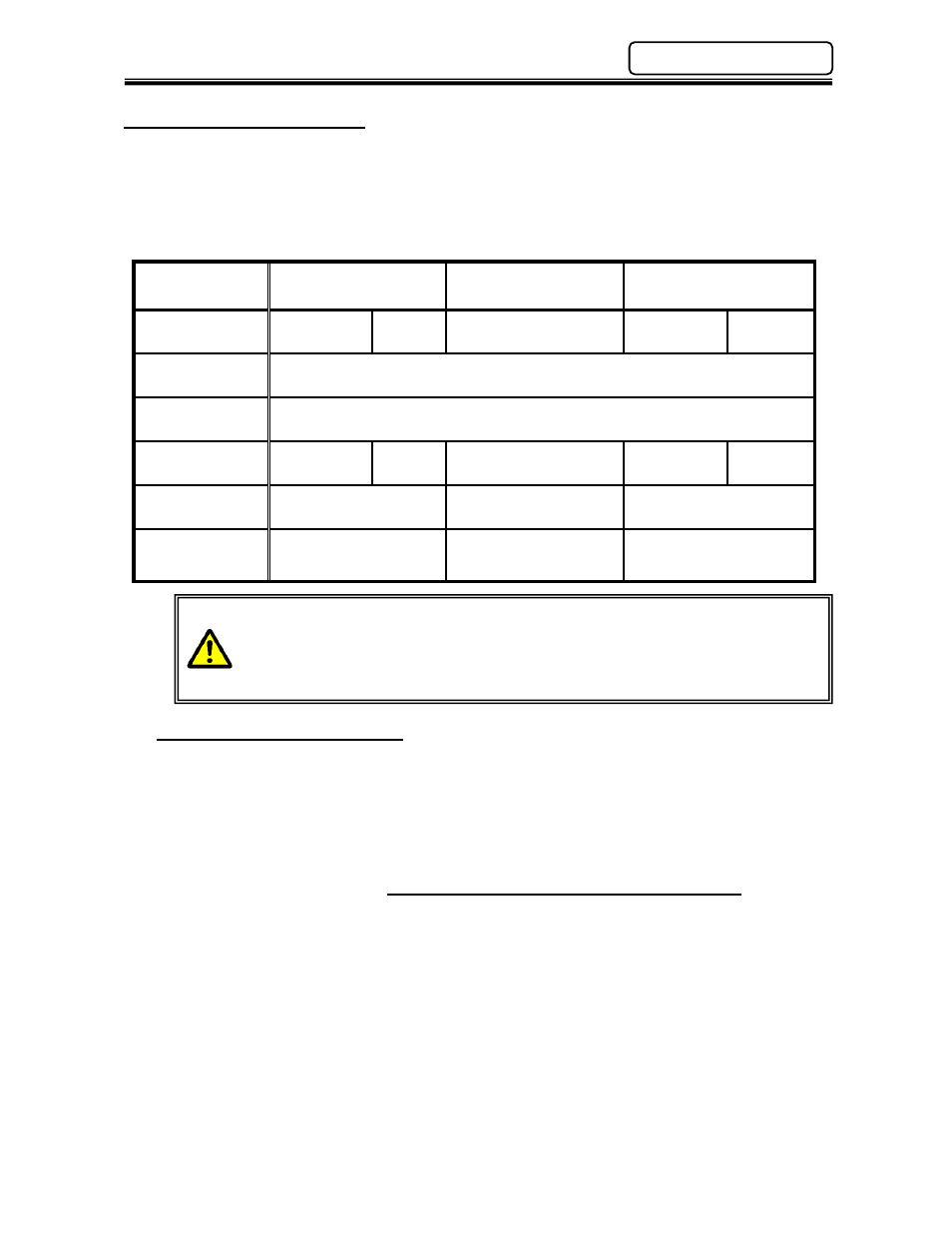

2.2 SAN Unit Specifications

CPU:

32 bit RISC (Reduced Instruction Set CPU)

Data Communication:

RS485 (2 Ports) – 1 for DSP User Console Software

Parameter / Firmware Storage:

Flash ROM

SAN Unit

Type

SAN3 - 24S

SAN3 - 40S

SAN3 – 120S

Motor Type

RM1

RM2

RM3

RM4H

RM5

(B)

SAN Unit Input

Power

180~242VAC

, 3φ

SAN Unit

Frequency

50/60HZ

MAX. POWER

OUTPUT

60W

80W

200W

1500W

3000W

IN-RUSH

CURRENT

18A

38.6A

116.4A

SAN POWER

CONSUMPTION

18W

IDLE

31W

IN CYCLE

18W

IDLE

3

9

W

IN CYCLE

18W

IDLE

109

W

IN CYCLE

After powering down wait at least 5 seconds (1 minute recommended) before

powering up again. If the equipment is powered “ON” and “OFF” repeatedly

without this delay, the in-rush current circuit will stop the unit from functioning.

If this happens it may take up to five minutes before the unit will power up

again.

2.2.1 Duty Cycle Calculation

Duty Cycle is rated as a percentage of the time the motor is running to the overall cycle time of

the machine. This is an important factor in determining overload protection for servo amplifiers

and motors as it directly relates to the amount of power or heat dissipation of the motor / servo

package. The rated duty cycle for the

enFORCE

system is calculated as follows:

Duty Cycle Percentage (%) =

Tool Pressing Time x 100

Total Cycle Time (Tool Pressing + Tool Waiting)

Duty cycle ratings vary between tools. As a general rule, however, it should not exceed 60%. If

duty cycles remain above 60% for extended periods, a “Servo Amplifier Error / Overload” will

result (see Abnormal Code 8-10). Protection for high duty cycle is a standard feature of the

servo amplifier to prevent servo or motor damage.

Chapter 2: Specifications