LINK Systems System 1100 Tonnage Monitor User Manual

Page 69

INSTALLATION

___________________________________________________________________

5-10

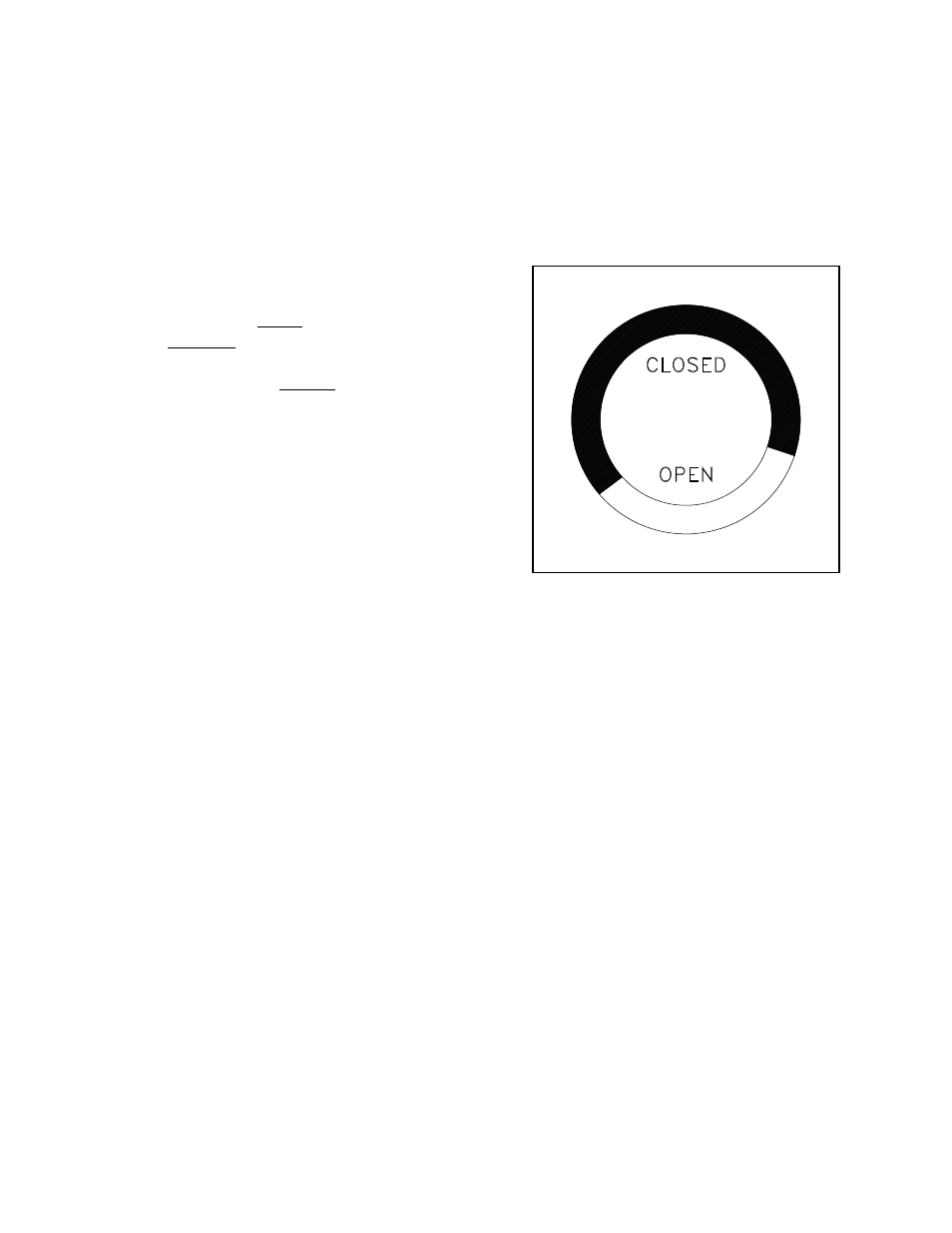

Figure 24. Setting of

Optional Zeroing Cam

Switch.

switch contact can be connected to the machine for grounding.

2)

If an ungrounded machine control system is present, run a wire

from the second side of the cam switch back to the GND

terminal adjacent to the EOC terminal on the Logic board.

3)

Adjust the zeroing cam switch as

shown in Figure 23. The cam

switch must be set to open

before the machine tooling

exerts force on the downstroke,

and close after all tooling and

stripper forces are relieved on

the upstroke.

4) O n

m a c h i n e s

t h a t a r e n o t

crankshaft driven, such as

hydraulic power presses, a limit

switch that is held closed when

the slide is in the upper

section of the stroke can be

used instead of a cam switch.

Always run cam switch or limit

switch wires in separate conduit

from 115VAC or higher voltage

conductors.

5.4.4 Connecting Optional Data Window Cam Switches

1) Data windows are used to display and place setpoints on

tonnage other than the absolute peak tonnage. The data window

cam switches should be setup as discussed in section 3.6.

When data windows are to be used, connect a wire from one

contact of each data window cam switch to the System 1100 data

window terminals located on the Logic board is the Logic Unit.

The four data window terminals are labeled DW1, DW2, DW3 and

DW4. If the System 1100 is grounded to the machine ground the

other contact of all the data window cam switches can be

connected to the machine for ground.

2)

If an ungrounded machine control system is present, wire the

other data window cam contacts to the GND terminal adjacent to

the data window terminals on the System 1100 Logic board.

3)

Always run data window can switch wires in separate conduit