LINK Systems System 1100 Tonnage Monitor User Manual

Page 65

INSTALLATION

___________________________________________________________________

5-6

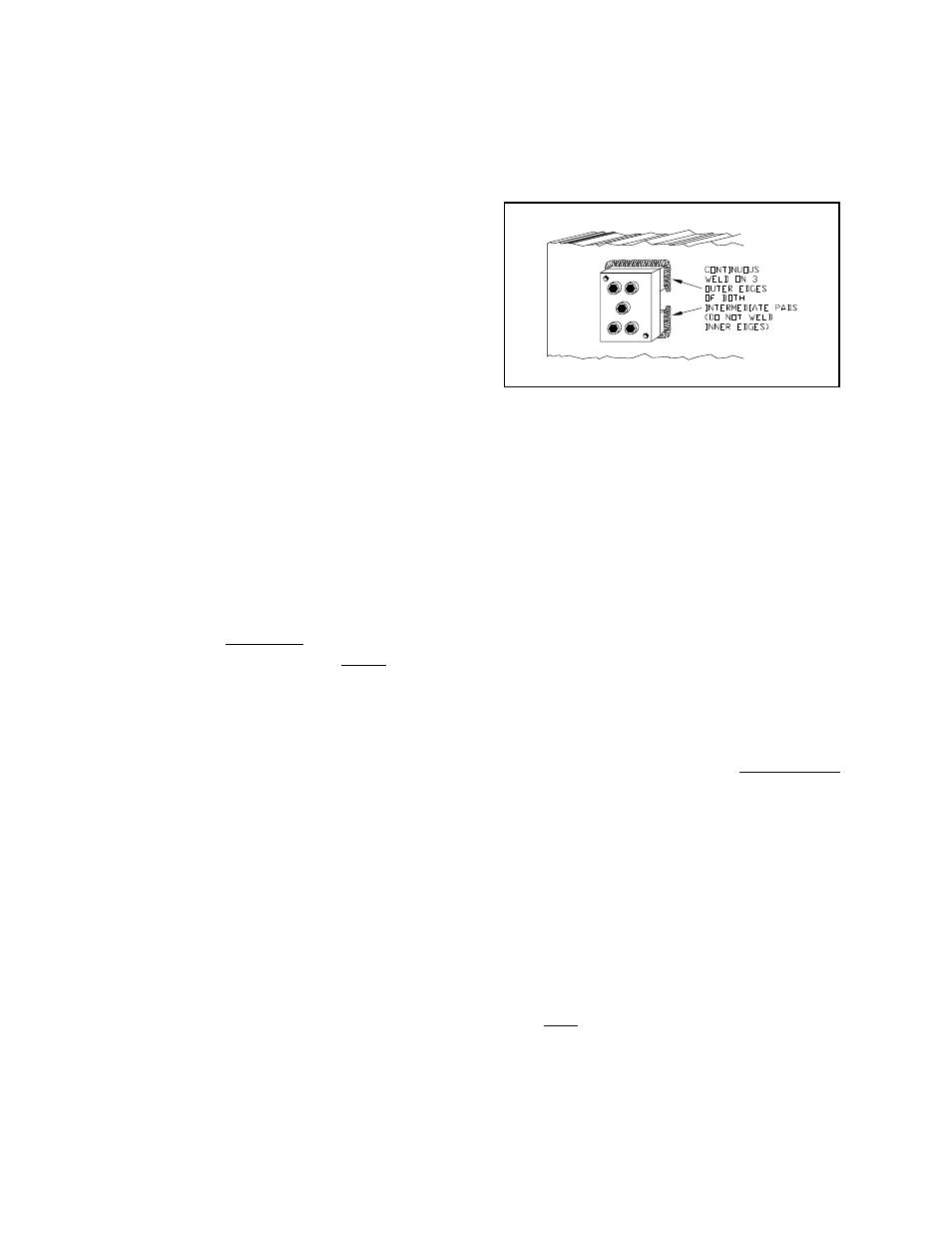

Figure 22. LST-1000 Weld

Pads.

4)

Assemble the intermediate pads to the alignment/clamping

fixture using the 1/4 x 28 bolts provided, as shown in Figure

20.

5)

Hold the alignment/clamping

fixture firmly on the

mounting area in the

direction of tension or

compression of the structural

member or, alternatively,

drill a 5/8 inch deep hole

through the center hole of

t h e a l i g n m e n t / c l a m p i n g

fixture, tap for 1/4 x 28

threads, and bolt the

alignment/clamping fixture to the mounting area through the

center hole. Tack weld both sides of each intermediate pad to

the mounting surface first, then continuously weld the out

ends and sides of the intermediate pads to the mounting

surface as shown in Figure 21.

6)

Remove the alignment/clamping fixture and bolt the LST-1000

strain link to the pre-tapped holes in the intermediate pads.

Make certain that the washers provided with the strain link

kit are placed over the strain links. Torque the 1/4 x 28

bolts to 150 in-lbs. A calibrated torque wrench is the

preferred tool to torque the bolts.

7)

Mount the protective cover box provided in the strain link

kit, if used, centrally over the strain link. It is important

to mount the cover box before calibration begins. The cover

box mounting holes may slightly change the strain sensed by

the strain links.

5.2.3 Intermediate Adhesive Pad Mounting

1)

Repeat steps 1-4 of the procedure for Intermediate Weld Pad

Mounting.

2)

Thoroughly clean the mounting surface and intermediate pads

with a solvent such a perchloroethylene or triclorethylene,

etc.. It is important to remove all grease or oil from the

surfaces to be bonded.

3)

Mix the epoxy cement provided with the intermediate adhesive