LINK Systems System 1100 Tonnage Monitor User Manual

Page 49

THEORY OF OPERATION

___________________________________________________________________

3-12

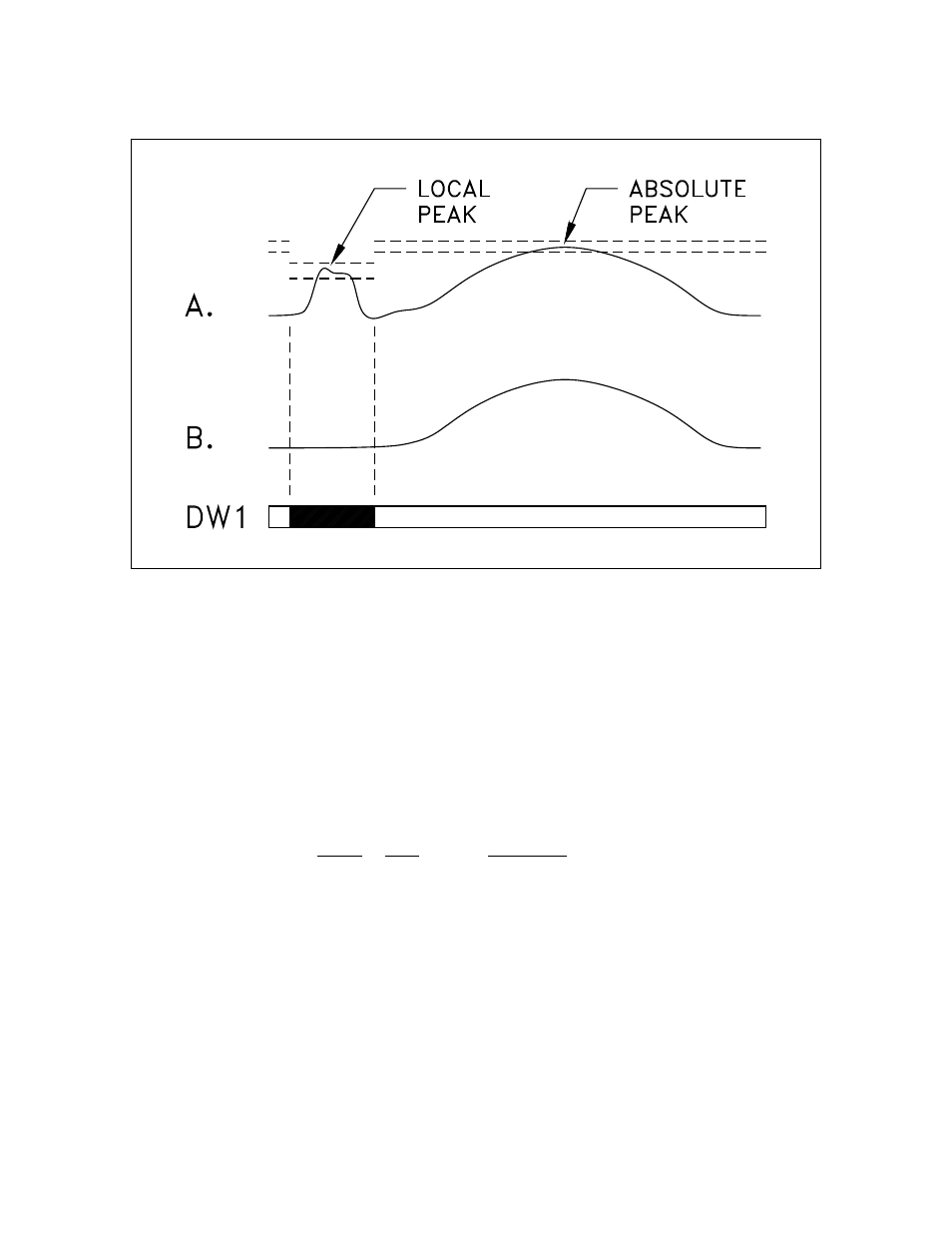

Figure 11. Use of a Data Window.

The tonnage verses time graph in Figure 10A is for a two station

die. The first station stamps a logo onto the part (absolute peak)

and the second station cuts out the part (local peak).

Since the absolute peak tonnage is created by the coining of the

logo, the local peak is not checked using a normal peak tonnage

monitor. The local peak could completely disappear as shown in

Figure 10B and a normal peak tonnage monitor would not detect any

anomaly in the process. This is exactly what would happen if the

material did not feed between strokes. Using a single data window,

however, places a high, low, and reverse tonnage setpoint on the

local peak.

Data window cams should be set to turn on before the local peak and

turn off after the local peak. When a data window input is active

(cam closed), the corresponding data window setpoints become

active. When no data window inputs are active (all open) the

absolute peak setpoints are active. This is illustrated in Figure

10 with the active setpoints shown as horizontal dashed lines.

In the maximum configuration the System 1100 can use five groups of

setpoints (peak & 4 data windows). On a four channel unit using