LINK Systems System 1100 Tonnage Monitor User Manual

Page 44

THEORY OF OPERATION

___________________________________________________________________

3-7

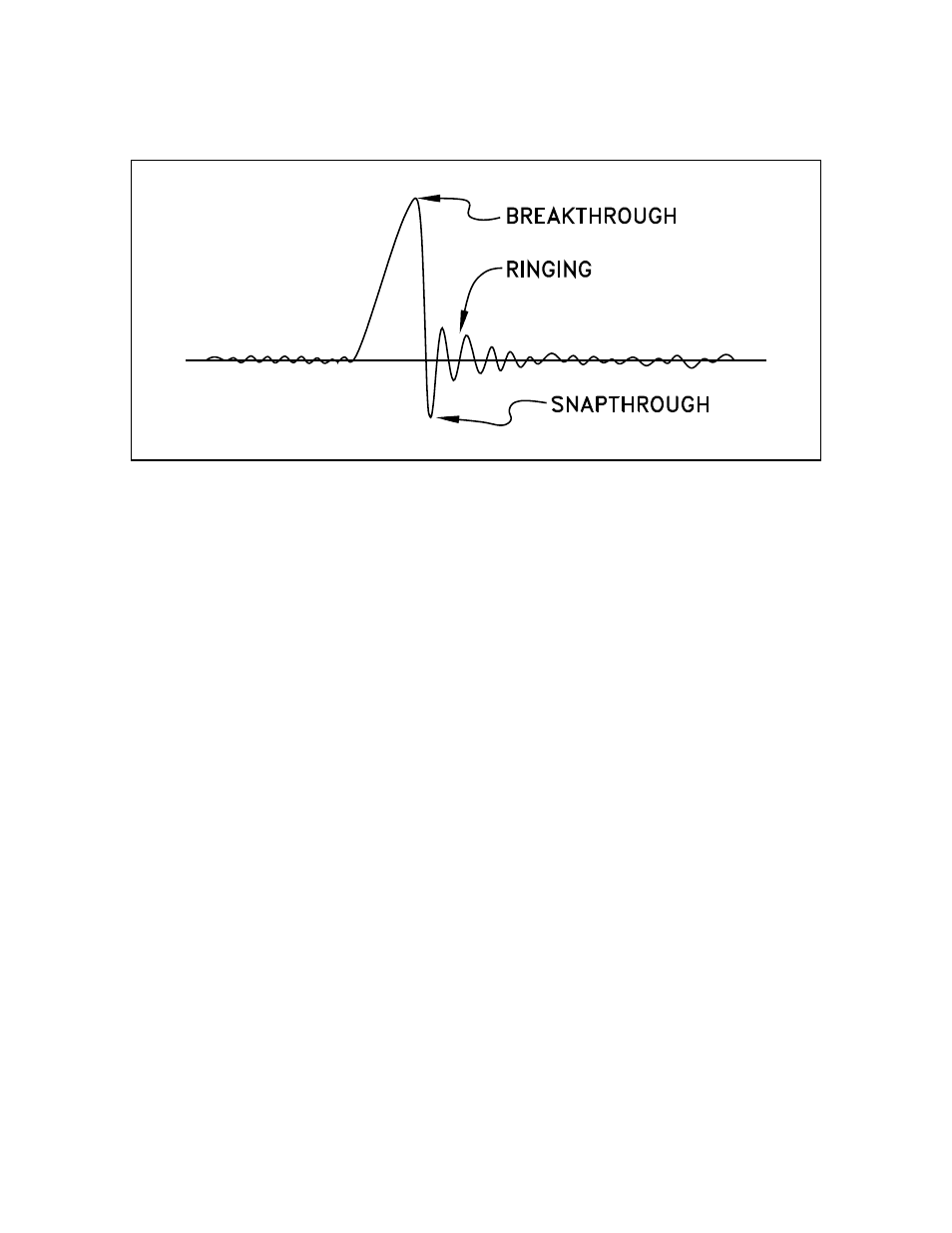

Figure 9. Structural Ringing.

The positive going signal is generated by machine frame stretch as

the tooling builds up force on the material. The signal increases

until the tooling breaks through the partly sheared material,

suddenly releasing the machine load to zero. The sudden release of

load causes the machine structure to rebound, creating the dying

oscillations (ringing) in the machine structure after material

breakthrough. The first negative peak of the oscillation is the

largest strain caused in the machine frame due to ringing, and is

often referred to as the "snapthrough" force. In effect, the

energy stored in the machine's frame under load creates a reverse

load on the machine when suddenly released.

Depending on structural mass and stiffness, ringing generally dies

out in a few milliseconds to a few hundredths of a second. This

short response normally has no effect on tonnage monitor accuracy

as long as machine speeds are less than 600 strokes per minute. At

speeds greater than 600 strokes per minute, the ringing may not die

out between load signals, and can cause a small offset in tonnage

monitor readings because the continuous ringing between load

signals interferes slightly with automatic zeroing circuits.

Ringing normally doesn't occur in forming, coining, forging, or

powdered metal compacting operations. The load on these operations

is released slowly by the machine ram or slide in the upstroke.

3.4.3 Structural Nonlinearity and Eccentric Loading