Index – Reznor B Unit Installation Manual User Manual

Page 39

Form I-F/B, P/N 98126 R21, Page 39

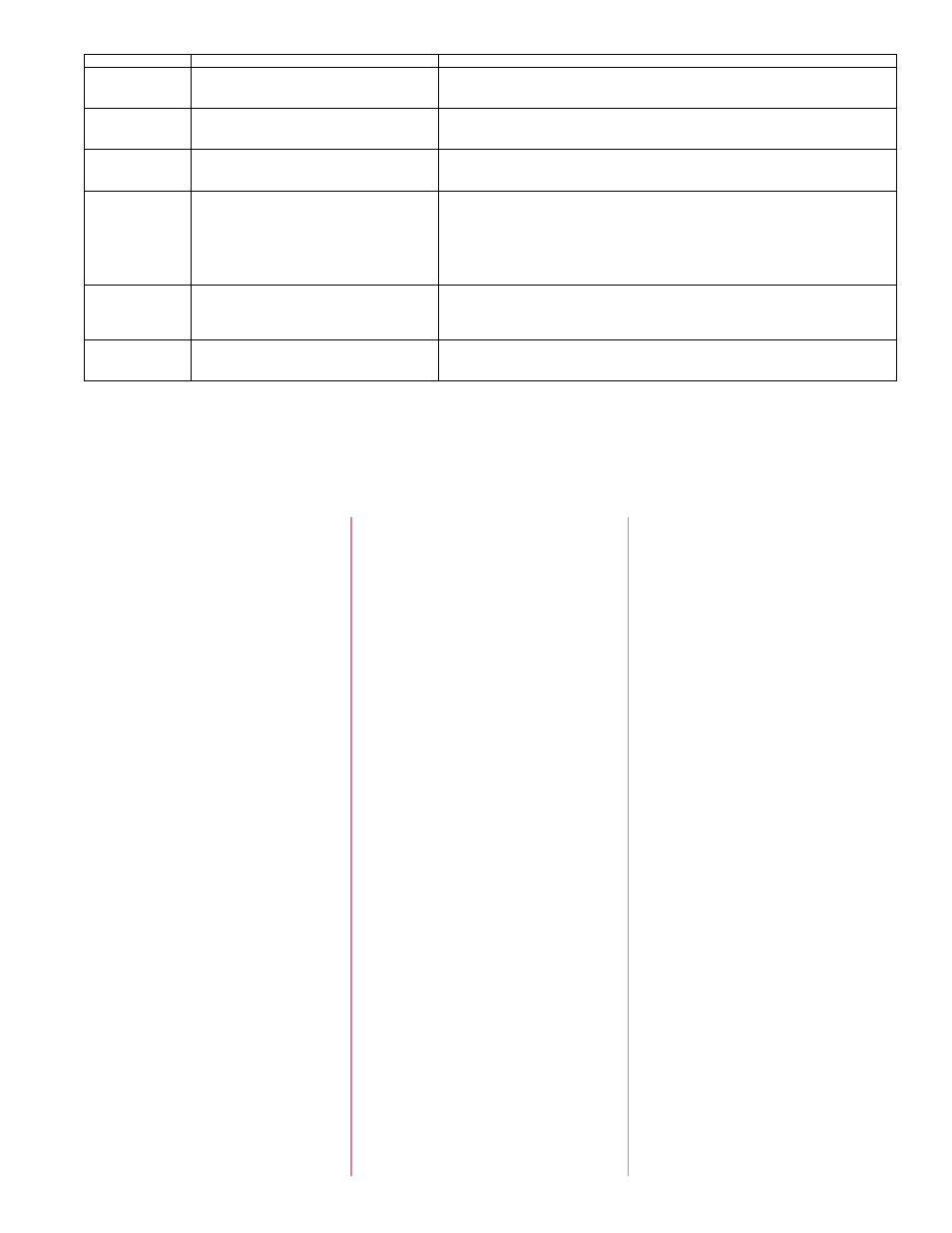

TROUBLE

PROBABLE CAUSE

REMEDY

No heat (Heater

Operating)

1. Incorrect manifold pressure or orifices.

1. Check manifold pressure (See Paragraph 6.1).

2. Cycling on limit control.

2. Check air throughput (See Paragraph 16).

3. Improper thermostat location or adjustment.

3. See thermostat manufacturer's instructions.

Cold air delivered 1. Fan control improperly wired

1. Connect as per wiring diagram.

On Start-up

2. Defective fan control.

2. Replace fan control.

During Operation 3. Incorrect manifold pressure.

3. Check manifold line pressure (See Paragraph 6.1).

Motor will not run 1. Circuit open.

1. Check wiring and connections. .

2. Fan control inoperative.

2. Replace fan control.

3. Defective motor or capacitor.

3. Replace motor or capacitor.

Motor turns on

and off while

burner is operating

(See motor cuts

out on overload

below)

1. Fan control improperly wired.

1. Connect as per wiring diagram.

2. Defective fan control.

2. Replace fan control.

3. Poor contact between fan control and heat

exchanger tube. Surface contact is required.

3. Check for bent mounting or loose mounting screws.

4. Motor overload device cycling on and off

4. Check motor load against motor rating plate. Replace motor if needed.

5. Low ambient temperature (less than 40°F)

causing false cycling

5. Install fan delay kit (See Paragraph 8.1).

Fan motor cuts

out on overload

1. Low or high voltage supply .

1. Correct electric supply.

2. Defective motor.

2. Replace motor.

3. Poor air flow.

3. Clean motor, fan and fan guard.

4. Defective bearing or lubrication.

4. Lubricate bearings or replace motor.

Blower motor

cuts out on

overload

1. Improper motor pulley and/or adjustment.

1. See instructions in Paragraph 6.5.

2. Improper static pressure in the duct system.

2. Adjust duct system dampers.

3. Low voltage.

3. Check power supply.

INDEX

A

Air Shutter Adjustment 31

B

Belt Tension 22

Blocked Vent Switch 30, 37

Blower 36

Blower/Filter Cabinet 19

Blower Operation 22

Blower Rotation 23

Blower Speed Adjustment 22

Burner Air Adjustment 31

Burner Orifices 35, 36

Burner Rack Removal 34

Burner Rack Support 34

C

Carryover 36

Clearances 8

Combustion Air Requirements 4

Confined Space 4

Electrical Supply Connections 24

Contact 40

Control Wiring 24

D

Vent Control Damper 19

Derating by Valve Outlet 15

Dimensions 9

Direct Drive 22

Unit Discharge 20

Downturn Air Nozzles 20

Duct Flange 20

E

ECO Control 37, 38

Electrical Supply and Wiring 23

F

Fan 22, 36

Fan Blade 37

Fan Control 30, 38

OPTIONAL 50 HERTZ OPERATION 24

Flash Carryover 36

Field assembly of the flue outlet 5

G

Gas Supply and Connections 13

Guard Options - Model B 7

H

Hanger Kits 12

Hanging the Heater 11

Hazard Labels 2

Heat Exchanger 36

High Altitude Installation 5

I

Ignition System 31, 35, 36

Inlet Air - Blower Model B 19

Installation Codes 3

L

Lifting 11

Limit 37, 38

Heater Location 3

Optional Vertical Louvers 20

M

MAINTENANCE 33

Maintenance Schedule 33

Multiple Heater Control 25

N

Downturn Nozzles 20

O

Orifice Pressure Settings 15

P

Pilot 31, 35, 36

Piping Connection 14

Polytube Adapter 21

Power Venting 19

Preparing the Heater for Installation 4

Outlet (Manifold) Pressure by Elevation

15

S

SAFETY 1

Spark Gap 36

Start-Up 32

Suspending 11

T

Troubleshooting 38

U

Uncrating and Inspecting 4

V

Check Valve Outlet (Manifold) Pressure

15

Gas Valve 30, 33

Vent Control Damper 19

Venting 16

Venting Arrangement 18

Venting Requirements 16

Vent Outlet 5

Vent Outlet Instructions for Size 125 6

Vent Outlet Instructions for Sizes 25, 50,

75, 100, 165 and 200 6

Vent Outlet Instructions for Sizes 250,

300 and 400 7

Vent Outlet Positions 6

Vent Outlet Sizes 16

Vent System 37

Vent with Condensate Drain 17

Vertical Louvers 20

Supply Voltage 23, 24

W

Warranty 3

Weights 11

Wiring Diagrams 26