Mechanical (cont'd), 2 venting, 1 gas piping and pressures (cont'd) – Reznor B Unit Installation Manual User Manual

Page 16

Form I-F/B, P/N 98126 R21, Page 16

6.2 Venting

3. With the manual valve positioned to prevent flow to the main burners, connect

a manometer to the 1/8” pipe outlet pressure tap in the valve. Use a fluid-filled

manometer that is readable to the nearest tenth of an inch w.c.

4. Remove the cap from the pressure adjusting screw and adjust the manifold

pressure to the pressure setting selected from the table. Cycle the main burners

once or twice to properly seat the adjustment spring in the valve.

Re-check the pressure. If necessary, re-adjust the pressure. When the pressure

is correct, remove the manometer and replace the cap. Check for leaks at the

pressure tap fitting.

5. With the heater operating determine that the inlet pressure to the heater for

natural gas is between 5 and 14 inches w.c. and for propane between 10 and 14

inches w.c. Take this reading as close as possible to heater (Most heaters are now

equipped with gas valves that have an inlet pressure tap.)

If the inlet pressure

is not within the specified range, the inlet pressure must be corrected and

Steps 3 and 4 repeated.

6. Find the High Altitude Adjustment label in the plastic bag that contained these

instructions. Using a permanent marker, fill-in the pressure setting. Adhere the

label on the heater near the gas valve so that it is conspicuous to someone

servicing the valve and/or the heater.

6.1.2 Manifold or

Orifice Pressure

Settings (cont'd)

DANGER: Failure to provide proper venting could result in death,

serious injury, and/or property damage. This heater must be installed

with a vent connection and proper vent to the outside of the building.

Install vent in accordance with Part 7, Venting of Equipment, of the

National Fuel Gas Code, ANSI Z223.1 (latest edition) or applicable

provision of national, state or local codes. A Canadian installation

must be in accordance with the CSA B149.1 and B149.2, Installation

Code for Gas Burning Appliances and Equipment, and applicable

local codes. Also, follow venting recommendations listed below.

Safe operation of any gravity-vented gas equipment requires a properly

operating vent system, correct provision for the combustion air (See

Paragraphs 2.2 and 4.1) and regular maintenance and inspection. See

Hazard Levels, page 2.

6.2.1 Vent Outlet

Sizes

6.2.2 Venting

Requirements - All

Models

1. Provide a minimum clearance of 18" (457mm) between the drafthood relief

opening and any obstruction. Do not expose the relief opening to wind drafts from

any source such as from an overhead door or adjacent air handling equipment.

2. The unit is equipped with a built-in draft diverter, consequently an external draft

diverter

MUST NOT be installed in the vent connector or any internal alterations

made. Do not install a manual damper or other fixed restriction in the vent

connector.

A gravity-vented unit heater manufactured after August 7, 2008, MUST be installed

with either an automatically controll

ed motorized vent damper (Option AV7) or

power venting (Option CA).

3. Vent pipe should be a minimum of 26 gauge galvanized steel or other non-

corrosive material. Double wall, Type B vent such as Metalbestos or Amerivent

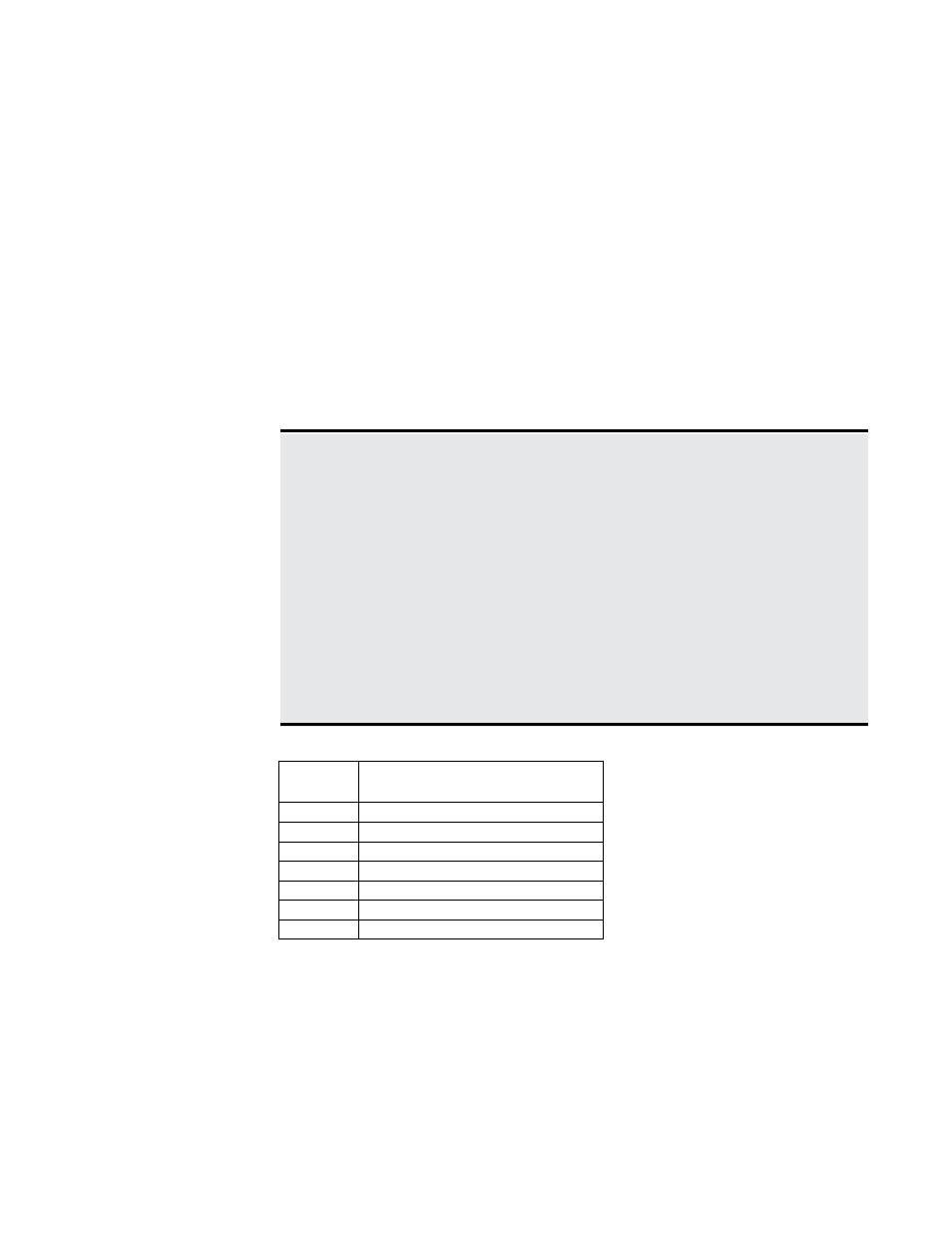

Heaters have the following vent outlet sizes:

Model

Size

Size Configuration of Horizontal/

Vertical Vent Outlet

25 - 50

4" Round

75

5" Oval

100

6" Oval

125

7" Oval

165 - 200

8" Oval

250 - 300

10" Oval

400

12" Oval

6. Mechanical

(cont'd)

6.1 Gas Piping

and Pressures

(cont'd)

NOTE: Standard units

manufactured prior to 10/89 (Serial

No. Date Code prior to AOJ) have

a round fixed vertical vent outlet in

the size listed. Units manufactured

prior to 10/89 with Option BT1

have the horizontal/vertical vent

outlet.