Mechanical (cont'd), 5 fan, blower, and drive – Reznor B Unit Installation Manual User Manual

Page 22

Form I-F/B, P/N 98126 R21, Page 22

6. Mechanical

(cont'd)

6.5 Fan, Blower, and

Drive

6.5.1 Fan Operation - Model F

The fan motor is equipped with thermal overload protection of the automatic reset type.

Should the motor refuse to run, it may be because of improper current characteristics.

Make certain that the correct voltage is available at the motor.

Blower Model

Sizes 25-100 are standardly equipped with a direct drive motor; an

optional belt drive motor is available on Sizes 50-100. Blower Model

Sizes 125-400

have an adjustable belt drive motor.

As part of the Check/Test/Start (Paragraph 9), check the belt for proper tension and

check that the setscrews are tight to the shaft.

Proper belt tension is important to the long life of the belt and motor. A loose belt will

cause wear and slippage. Too much tension will cause excessive motor and blower

bearing wear. Adjust the belt tension by turning the adjusting screw on the motor base

until the belt can be depressed 1/2-3/4" (13-19mm). (See

FIGURE 23.) After correct

tension is achieved, re-tighten the locknut on the adjusting screw.

Most blower motors are equipped with thermal overload protection of the automatic

reset type. If a motor is not equipped with thermal overload protection, the unit will be

equipped with a starter. The adjustable setting on the starter will be factory set to match

the amp draw of the motor and sealed. No change should be made to starter set unless

the original motor is replaced.

Starters are supplied from the factory for manual reset operation. If an overload condi-

tion is experienced, the condition must be corrected, and the starter must be manually

reset.

After the installation is complete including all ductwork, check the amp draw of the

motor with an amp meter to verify that the motor amp rating on the motor nameplate

is not being exceeded. Amps may be adjusted downward by reducing blower speed or

by increasing the duct system static pressure. The temperature rise must be within the

range specified on the unit rating plate.

6.5.2 Belt Tension and

Blower Operation -

Model B

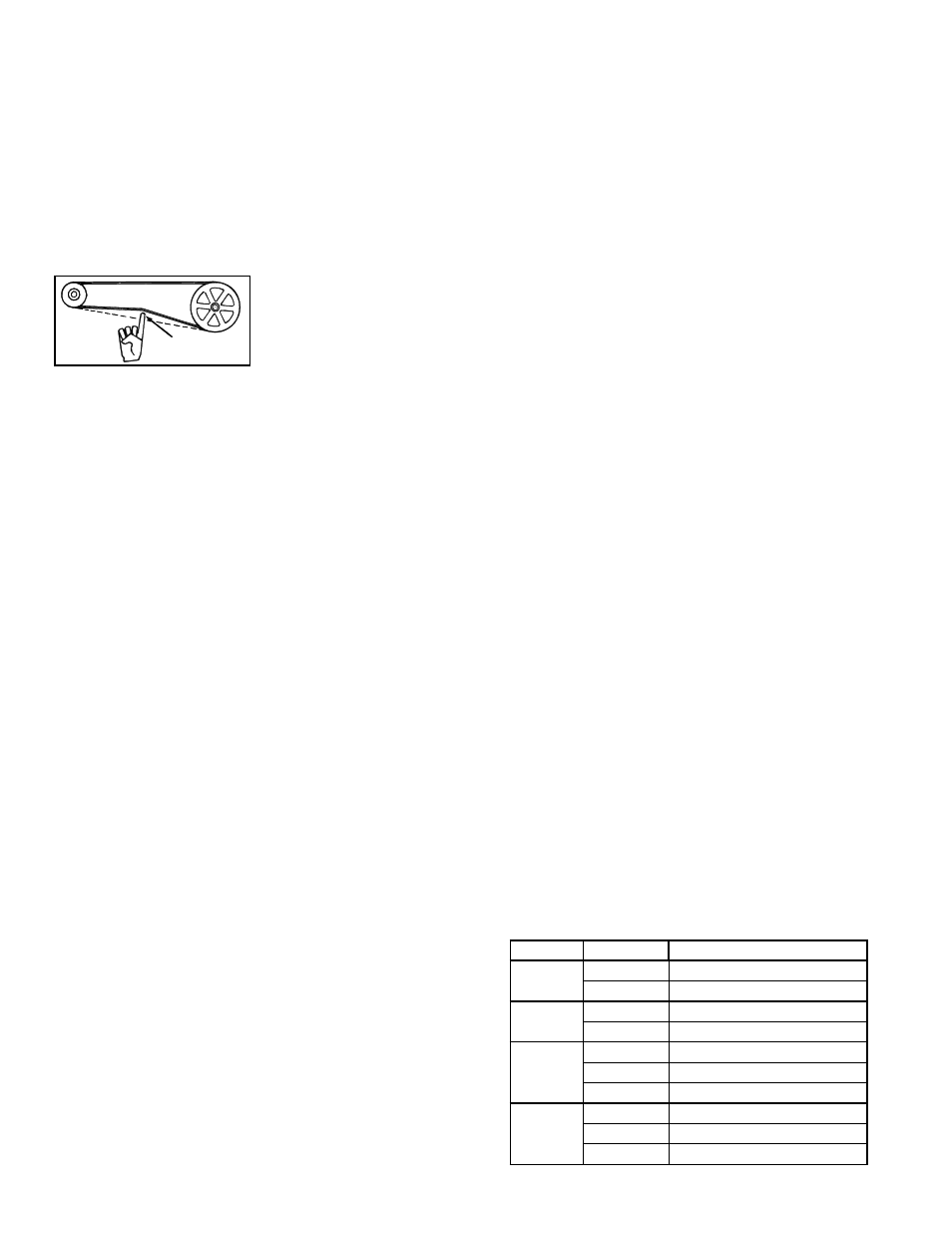

3/4 (19mm)

FIGURE 23 - Adjusting

Belt Tension

Blower Speed

Adjustment

The blower speed may be adjusted to achieve the desired outlet temperature, as long

as the adjustment is within the temperature rise and the static pressure limits shown

on the heater rating plate.

Direct drive motors are factory set as indicated in the chart

below.

Belt drive motors are factory set at the midpoint between maximum and mini-

mum blower speeds.

If the duct resistance is low, the blower may deliver too high an air volume; or if the

heater is operated without ductwork, it may deliver sufficient excess air to overload the

motor, causing the overload protector to cycle the motor. Reducing the blower speed

will correct these conditions. If ductwork is added to an installation, it may be neces-

sary to increase the blower speed. Decreasing blower speed will increase outlet tem-

perature; increasing blower speed will decrease outlet temperature.

Blower Model Sizes 25-100 with Direct Drive

Direct drive blower motors have multi-speed taps for speed adjustment. If your instal-

lation requires an adjustment of the blower speed, the motor may be re-wired to an

alternate tap by following these instructions.

1. Turn off the gas and the electric power.

2. Remove the left (left when

facing the back of the unit)

outer side panel of the

heater to reveal the wiring

connections.

3. Consult the wiring diagram

on the heater and follow

the chart on the right to

choose the wire connections

for the desired adjustment.

The asterisk(*) indicates the

factory-wired speed.

Size

Speed

Use these Two Motor Wires

25

*Medium

*Blue and White

Low

Red and White

50

*High

*Black and White

Medium

Blue and White

High

Black and White

75

*Medium

*Blue and White

Low

Red and White

*High

*Black and White

100

Medium

Blue and White

Low

Red and White