Reznor B Unit Installation Manual User Manual

Page 17

Form I-F/B, P/N 98126 R21, Page 17

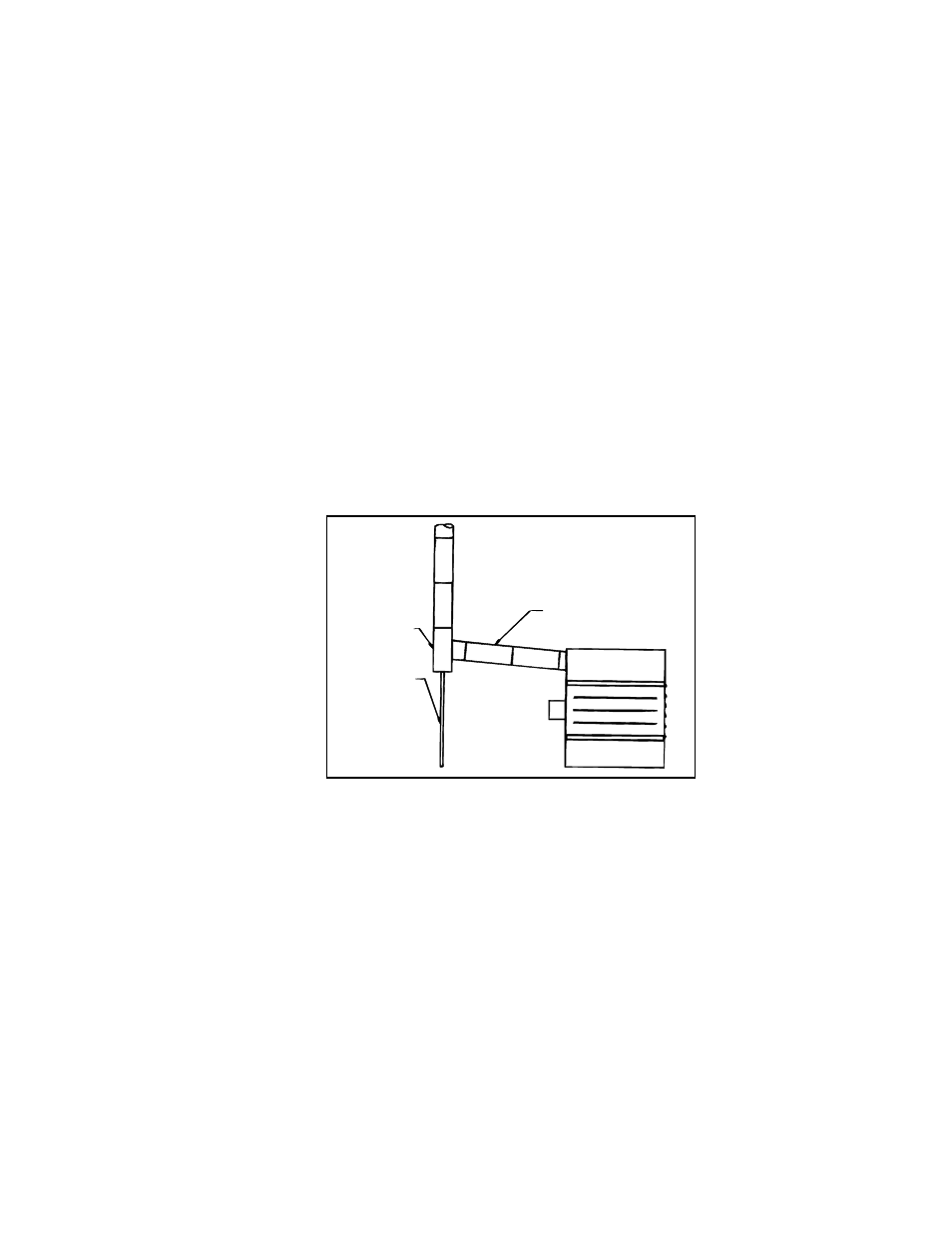

Slope upward at

least 1/4 per foot

(6mm per 305mm)

Tee

with cap

installed

Small

diameter

tubing

to drain

FIGURE 13 - Vent with

Condensate Drain

8. The vent connection may be made into a suitable permanent chimney or into a

gas vent. The effective area of the vent connector, gas vent or chimney when

connected to a single appliance shall not be less than the area of the appliance

drafthood outlet or in accordance with approved venting methods. The effective

area of the gas vent or chimney when connected to more than one appliance shall

not be less than the area of the largest vent connector plus 50% of the areas of

additional vent connectors or in accordance with approved venting methods.

Minimum permissible height of the vertical vent is five feet (1.5M) providing no

horizontal vent pipe connector is used. If a horizontal vent connector is necessary,

consult Vent Run Length Tables on page 18 or the National Fuel Gas Code or

the Canadian Installation Code for Gas Burning Appliances, for the maximum

permissible length of a horizontal pipe run (vent connector) for a given vertical

height of gas vent.

The gas vent or chimney should extend at least three feet (1M) above the highest

point where it passes through a roof of a building and at least two feet (.6M) higher

than any portion of a building or obstruction within a horizontal distance of ten

feet (3M). Terminate the vent pipe with a Reznor Option CC1 vent cap. (

NOTE:

When installing a Size 125, run the required 7" vent pipe and use a field-supplied

increaser to attach an 8" vent cap.)

See illustrations in

FIGURES 14, 15, and 16.

is recommended. Where it is necessary to run the vent pipe through an exterior

wall of combustible materials, a suitable thimble must be used. The vent pipe shall

have a clearance of at least six inches (152mm) from combustible materials, or as

is specified by the double-wall vent pipe manufacturer.

4. With the outlet on the heater in the horizontal position, it is recommended that a

12-18" (305-457mm) piece of straight pipe be connected to the flue collar before

installing an elbow. The horizontal vent pipe run should have a uniform rise of at

least 1/4" per foot (6mm per 305mm) of horizontal run in the direction of discharge.

The length of the lateral run must not exceed lengths showing in the vent tables

of the National Fuel Gas Code or the Canadian Installation Code for Gas Burning

Appliances. (See Vent Table on page 18.)

5. Lateral runs should be supported every six feet (1.8M) using a non-combustible

material, such as strap steel or chain. Do not rely on the drafthood or heater for

support of either horizontal or vertical vent pipe.

6. Vent connectors serving Category I heaters shall not be connected into any portion

of a mechanical draft system operating under positive pressure.

7. Where it is necessary to use a long run of vent pipe, or where the vent pipe is

exposed to cold air, condensation within the pipe may occur. There are two ways

to overcome or eliminate this problem.

(a) Prevent condensation by insulating the pipe so that the temperature of the flue

products never drops below 250°F.

(b) Use double-wall, Type B vent pipe which is recommended for the reduction or

elimination of condensate problems. Where extreme conditions are present and

condensate is anticipated, install a drain for condensate. (See

FIGURE 13.)