Maintenance and service (cont'd), 2 maintenance procedures (cont'd) – Reznor B Unit Installation Manual User Manual

Page 36

Form I-F/B, P/N 98126 R21, Page 36

FIGURE 44 - Pilot

Burner Spark Gap

(Spark Pilot)

.100 spark gap

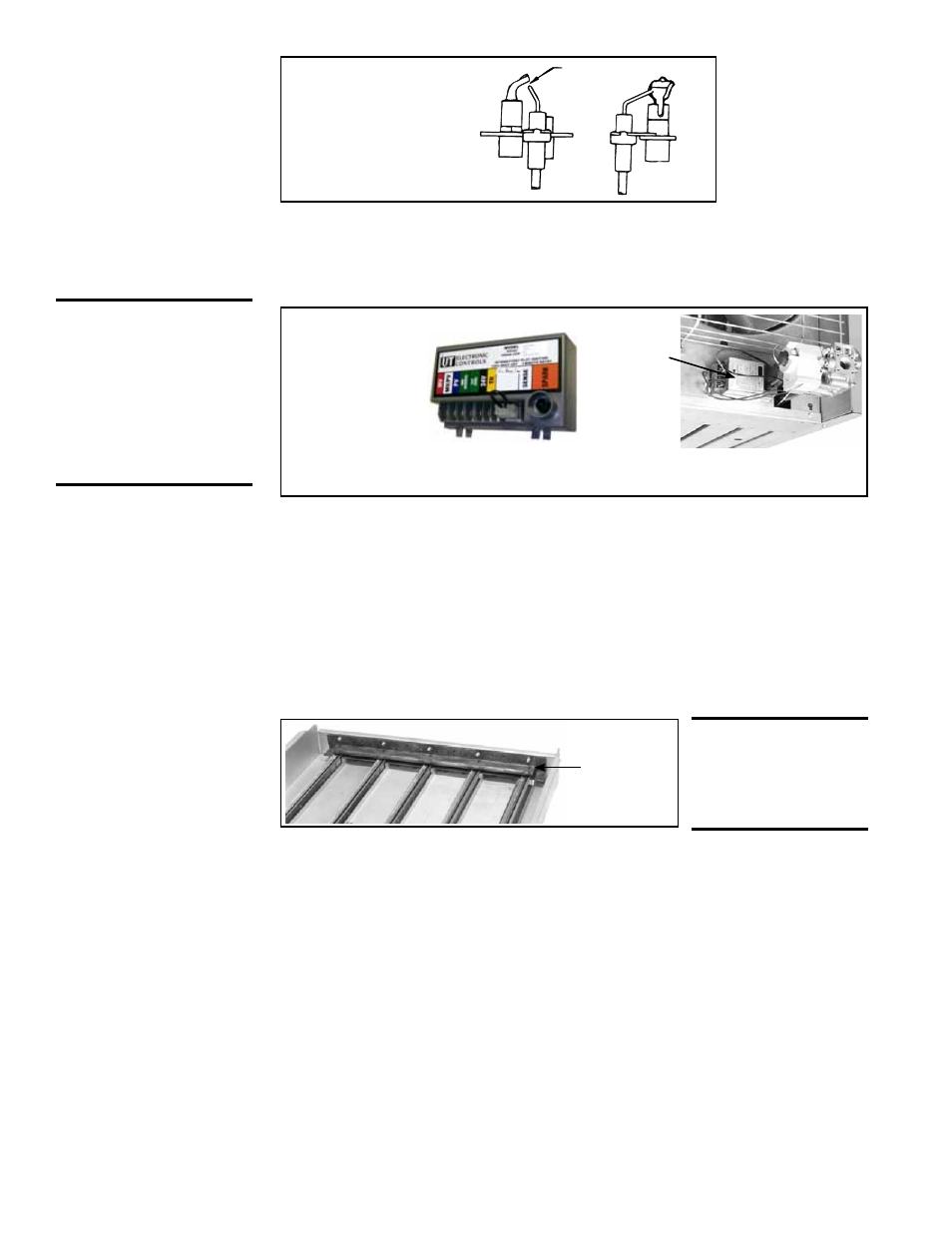

The

ignition controller of the optional intermittent electronic ignition pilot system is

visibly located on the back of the heater. (See

FIGURE 45.) Do not attempt to disas-

semble the ignition controller. There are no field replaceable components in the control

enclosure. However, each heating season the lead wires should be checked for insula-

tion deterioration and good connections.

FIGURE 45 - Ignition Controller,

UTEC 1003-514,

P/N 257010,

for Option AH3

Gas Control

Location

of Ignition

Controller

10.2.4 Burner Orifices

Heaters are shipped with orifices of proper size and type for gas and altitude specified

on the order. When ordering replacement orifices, give BTUH content, specific gravity

of gas, and altitude, as well as model and serial number of the heater.

Flash

Carryover

FIGURE 46 - Burner

Rack Flash Carryover

10.2.7 Fan or Blower

10.2.5 Flash

Carryover

See

FIGURE 46. The burner carryover system receives its gas supply from the main

burner ports. Check the carryover assembly and also the main burner ports for cleanli-

ness. Clean with air pressure.

CAUTION: Wearing

eye protection

when cleaning

this heater is

recommended.

10.2.6 Heat

Exchanger

Remove dirt and grease from the motor.

On fan model units, remove dirt and grease from the fan guard and blades. Use care

when cleaning the fan blades to prevent causing misalignment or imbalance. Check

that the hub of the fan blades is secure to the shaft.

On blower models,

remove the grease and dirt from the blower housing and check the

belt for wear and proper tension (See Paragraph 6.5).

Lubricate if the motor has oil cups or grease fittings. The motor supplied as standard

has lifetime lubrication and sleeve bearings.

On blower models, check current draw to motor rating plate.

The outside of the heat exchanger can be cleaned from the front of the heater with an

air hose and/or a brush. Remove all accumulated dust and grease deposits.

The inner surfaces of the heat exchanger can be reached for cleaning with the burner

rack removed. (See Paragraph 10.2.2.) Cleaning can be done with a long furnace

brush or a heavy wire to which steel wool has been attached. Brush up and down

inside each heat exchanger tube until all foreign material is removed. A flashlight is

helpful in examining the upper section of the tube.

Proper operation of the electronic spark ignition system requires a minimum

flame signal of .2 microamps as measured by a microampmeter.

10. Maintenance

and Service

(cont'd)

10.2 Maintenance

Procedures

(cont'd)

10.2.3 Pilot and

Ignition Systems

(cont'd)

CAUTION: Due to

high voltage on

pilot spark wire

and pilot electrode,

do not touch when

energized. See

Hazard Levels,

page 2.

Service NOTE: If replacing an earlier style of ignition controller, order replacement kit

P/N 257472 for a unit with recycling gas control Option AH2 or P/N 257473 for Option

AH3 gas control with lockout. (Option codes are listed on the unit wiring diagram.) Use

of a vent damper requires an ignition controller with lockout.