Reznor B Unit Installation Manual User Manual

Page 15

Form I-F/B, P/N 98126 R21, Page 15

6.1.2 Manifold or

Orifice Pressure

Settings

Measuring manifold gas pressure cannot be done until the heater is in operation. It is

included in the steps of the "Check-Test-Start" procedure in Paragraph 9. The following

warnings and instructions apply.

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result

in unregulated

manifold pressure

causing excess

overfire and heat

exchanger failure.

WARNING:

Manifold gas

pressure must

never exceed 3.5"

w.c. for natural gas

and 10" w.c. for

propane.

For Natural Gas: When the heater leaves the factory, the combination gas valve is set

so that the outlet gas pressure of a single-stage valve or high fire of a two-stage valve

is regulated to 3.5" w.c. Low fire on a two-stage valve is set to 0.9" w.c. Inlet supply

pressure to the valve for natural gas must be a minimum of 5" w.c. or as noted on the

rating plate and a maximum of 14" w.c.

For Propane: When the heater leaves the factory, the combination gas valve is set so

that the outlet gas pressure of a single-stage valve or high fire of a two-stage valve is

regulated to 10" w.c. Low fire on a two-stage valve is set to 3.8" w.c. Inlet supply pres-

sure to the valve for propane gas must be a minimum of 11" w.c. and a maximum of

14" w.c.

Before attempting to measure or adjust valve outlet (manifold) gas pressure, the inlet

supply pressure

must be within the specified range both when the heater is in opera-

tion and on standby. Incorrect inlet pressure could cause excessive manifold gas pres-

sure immediately or at some future time. If natural gas supply pressure is too high,

install a regulator in the supply line before it reaches the heater. If natural gas supply

pressure is too low, contact your gas supplier.

Instructions on How

to Check Valve Outlet

(Manifold) Pressure

(can only be done after

heater is installed):

1) With the manual valve positioned to prevent flow to the main burners, connect a

manometer to the 1/8" pipe outlet pressure tap in the valve.

NOTE: A manometer

(fluid-filled gauge) is recommended rather than a spring type gauge due to the

difficulty of maintaining calibration of a spring type gauge.

2) Open the valve and operate the heater. Measure the outlet pressure of the gas

valve. To measure low stage pressure on units equipped with a two-stage valve,

disconnect the wire from the "HI" terminal on the valve. (Be sure to reconnect the

wire.)

Normally adjustments should not be necessary to the factory preset regulator.

(For high altitude settings, see below.) If adjustment is necessary, remove the

cap from the adjustment screw(s). Set pressure to correct settings by turning the

regulator screw IN (clockwise) to increase pressure. Turn regulator screw OUT

(counterclockwise) to decrease pressure.

Derating by Valve Outlet (Manifold) Pressure Adjustment for High

Altitude Operation

If the heater is being installed above 2000 ft (610M) and it was determined in Para-

graph 3.2.1 that derating by valve outlet pressure adjustment is permissible, follow the

instructions that follow.

Instructions for Derating a Heater by Adjusting Valve Outlet Pressure

(The heater MUST have a single-stage gas valve and MUST be factory-

equipped for sea level operation.)

1. Check the rating plate to be certain that the heater is equipped for sea level

operation.

Do not attempt to derate by valve outlet pressure adjustment if

the heater is factory equipped for high altitude. Do not attempt to adjust

manifold pressure on heaters equipped with two stage gas valves.

2. Determine the required valve outlet (manifold) pressure for the elevation where the

heater will be operating. If unsure of the elevation, contact the local gas supplier.

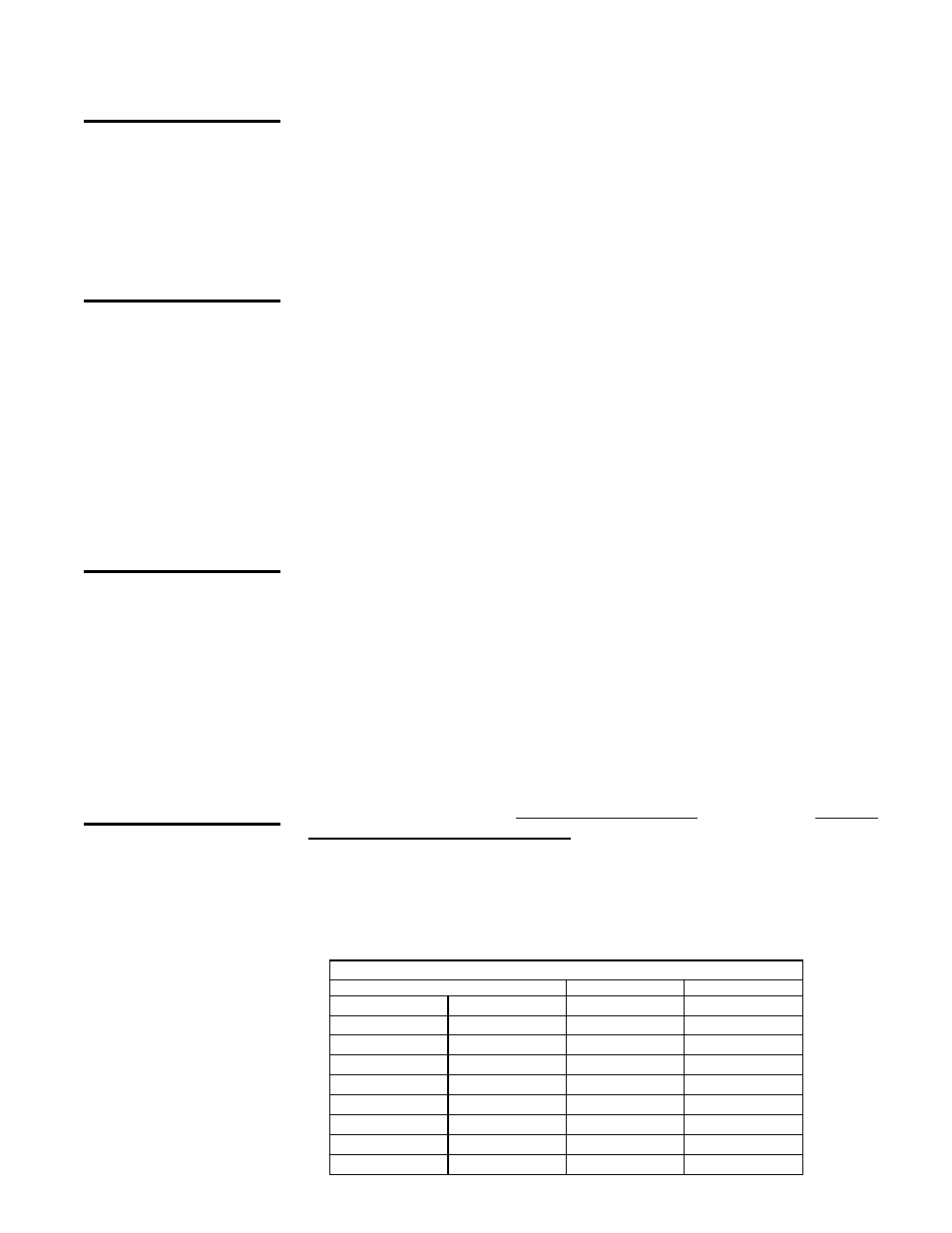

High Fire Valve Outlet (Manifold) Pressure by Elevation

Altitude

Natural Gas

Propane

Feet

Meters

(inches W.C.)

(inches W.C.)

0- 2000

0-610

3.5

10.0

2001-3000

611-915

2.8

7.7

3001-4000

916-1220

2.5

7.1

4001-5000

1221-1525

2.3

6.4

5001-6000

1526-1830

2.1

5.8

6001-7000

1831-2135

1.9

5.2

7001-8000

2136-2440

1.7

4.6

8001-9000

2441-2745

1.5

4.1