Combustion adjustment procedure, Units with current user interface – LAARS NeoTherm NTV (Sizes 150–285 MBTU/h) - Service Manual User Manual

Page 66

56

Service Manual NeoTherm 80 - NeoTherm 285

Combustion Adjustment Procedure -

Units with Current User Interface

WARNING

Improper adjustment of the high fire and low fire settings may lead

to poor combustion, increasing the amount of carbon monoxide

produced. Excessive carbon monoxide levels may lead to personal

injury or death.

Equipment required:

• Flue product analyzer

• 2 mm Allen wrench

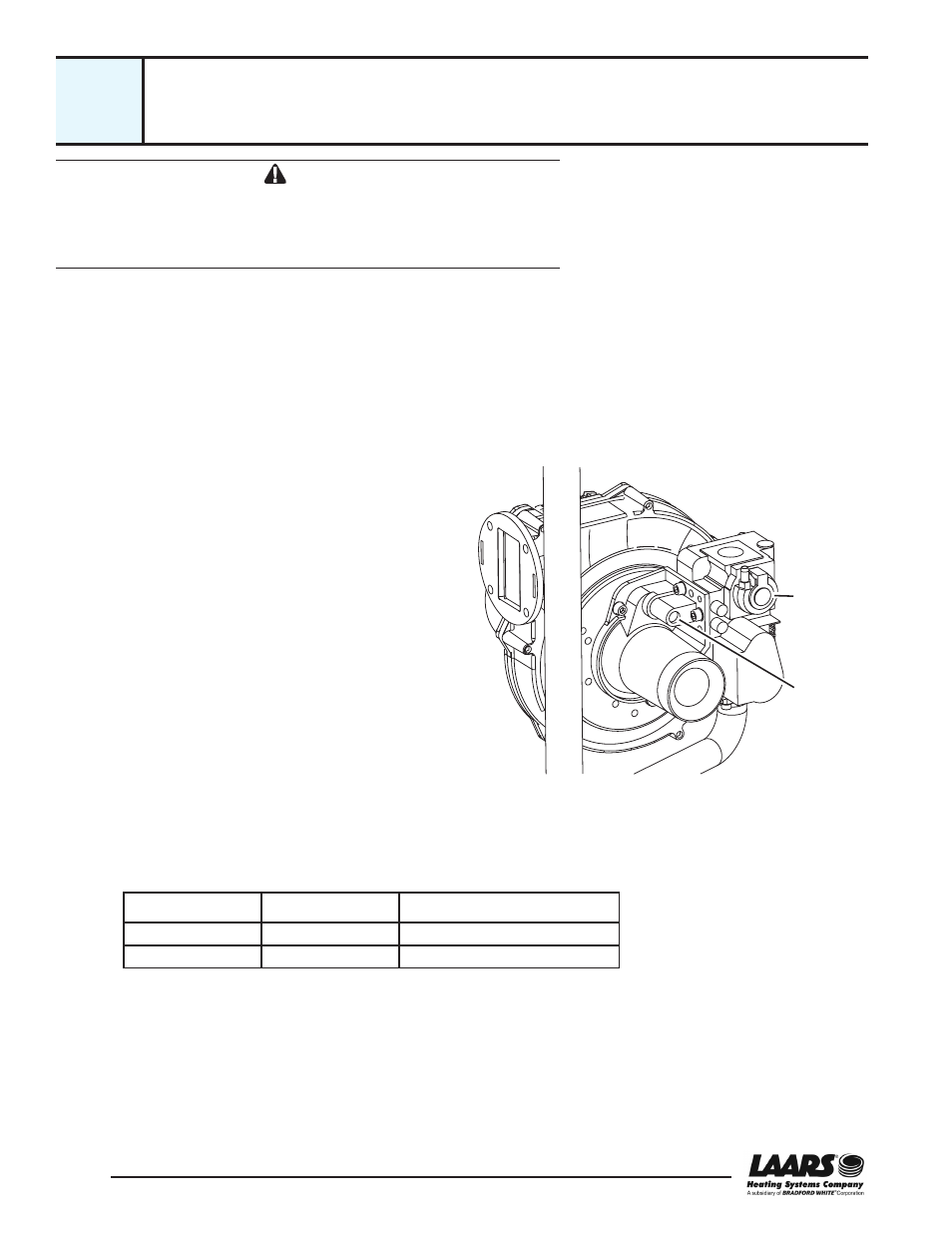

Fig. C3-1 - High- and low-fire adjustments on gas

valve - NT 85 through NT 285

Procedure:

1. Start by measuring the CO

2

and O

2

in the flue prod-

ucts at high fire. The controller has a feature that

makes it easy to go directly to the high fire condition.

The unit will operate at high fire for 5 minutes, then

shut down automatically.

How to get there: From the “Home” screen, press

“I” to go to “Info/ Install.” Choose “Test,” then go to

“Forced Rate.” Select “Set High Fire,” then select

“Start Test.”

The CO

2

readings should be between the values

shown in Table C3-1. If the CO

2

is not within the cor-

rect range, adjust the high fire setting. See Fig. C3-1

to locate the high fire adjuster screw. Slowly make

adjustments (1/16 of a turn at a time) until the CO

2

is within the range shown in the table. For the high

fire adjustment, turning the screw counter-clockwise

(CCW) opens the adjustment and makes the mixture

richer.

Gas Type

High Fire CO

2

Low Fire CO

2

Natural

8.5% to 9.0%

0.5% lower than high fire CO

2

Propane

9.8% to 10.0%

0.5% lower than high fire CO

2

Table C3-1 - CO

2

Range and Pressure Differential

Low fire

CO

2

adjustment

High fire

CO

2

adjustment

C3