B13 - testing the condensate trap level switch, B14 - removing and replacing the condensate trap, Testing the condensate trap level switch – LAARS NeoTherm NTV (Sizes 150–285 MBTU/h) - Service Manual User Manual

Page 41: Removing and replacing the condensate trap, B13 b14

31

Service Manual NeoTherm 80 - NeoTherm 285

Testing the Condensate Trap Level Switch

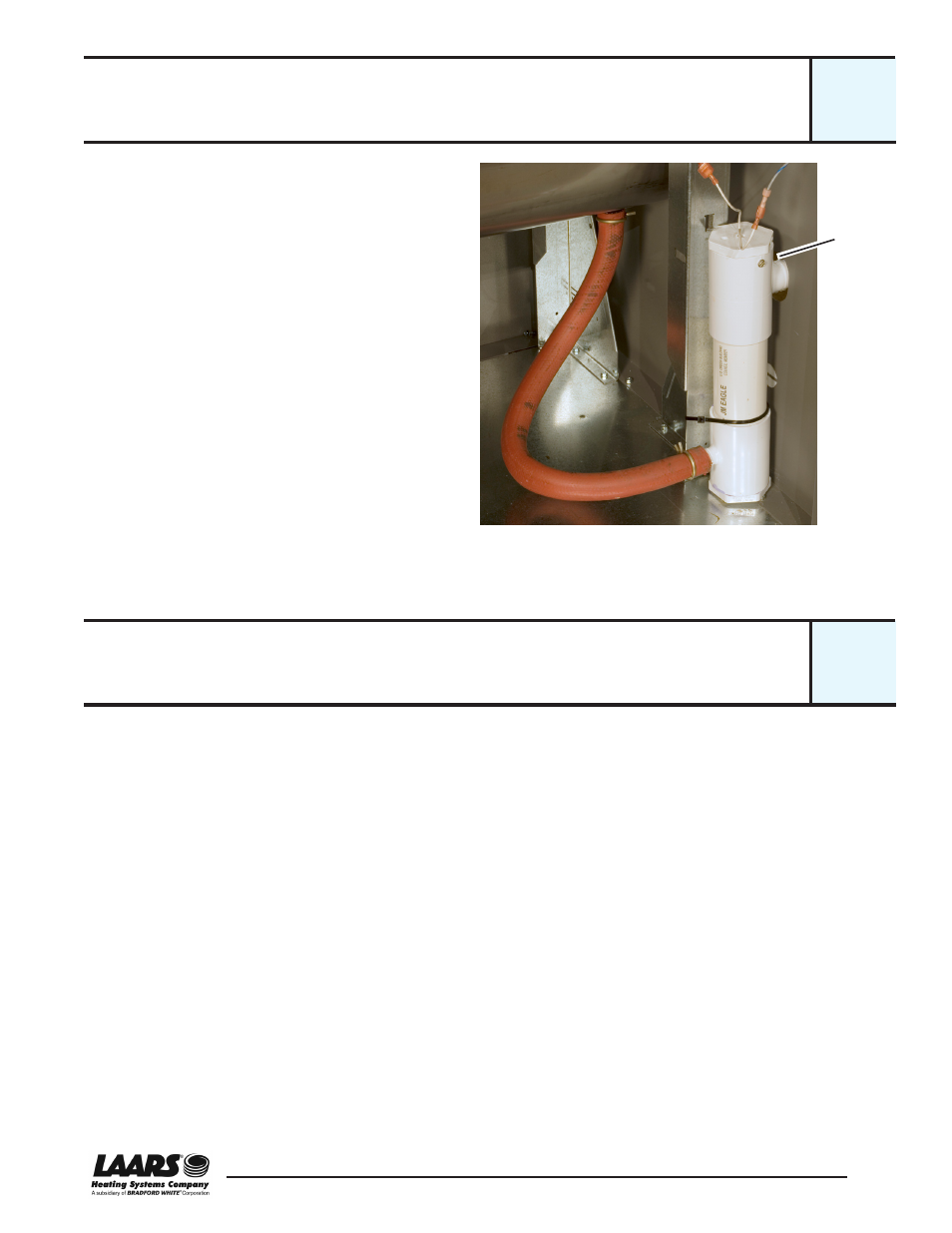

Fig. B13-1 - Small condensate trap assembly (typical)

Some operating conditions can cause small particles

of mineral material to be formed in the heat exchang-

er and collect in the condensate trap. The drain can

also be blocked if it is frozen or plugged with debris.

If the water cannot drain freely, it can back up into

the heat exchanger. The level switch is designed to

prevent this by shutting off the unit before the water

can reach the heat exchanger.

This assembly uses a float-type switch. To test, plug

the outlet (the higher fitting on the assembly). Mea-

sure the resistance across the switch contacts when

the assembly is empty. At this point, the contacts

should be closed (no resistance). Next, add water at

the inlet (the lower fitting). As the water level rises in-

side the assembly, you should see the contacts open

(infinite resistance).

Removing and Replacing the Condensate Trap

The NeoTherm unit is designed to operate in the “condensing” mode.

The combustion of natural gas produces a lot of water vapor. In the NT

unit, this water vapor is condensed out of the exhaust gas inside the heat

exchanger. The water is collected from the bottom of the heat exchang-

er, and sent to the condensate trap. The trap includes a float valve. If

the condensate drain is plugged or blocked for some reason, the float

rises inside the trap. If the water rises high enough, the float trips a

switch and prevents the NT unit from firing. This means the condensate

water can never back up into the heat exchanger.

Note that the condensate water can be hot. The water is also acidic, and

can damage metal pipes.

The photo above shows a condensate trap from a smaller NT unit. The

water enters through the hose at the bottom of the unit, and exits through

the top. At the top of the unit you can see the two wires for the float

switch.

The cap on the PVC assembly is held in place by a set-screw. Once you

remove this screw, you can remove the cap and unscrew the switch.

Set-

screw

B13

B14