Great Planes ESP6 Easy Sport 60 - GPMA0152 User Manual

Page 45

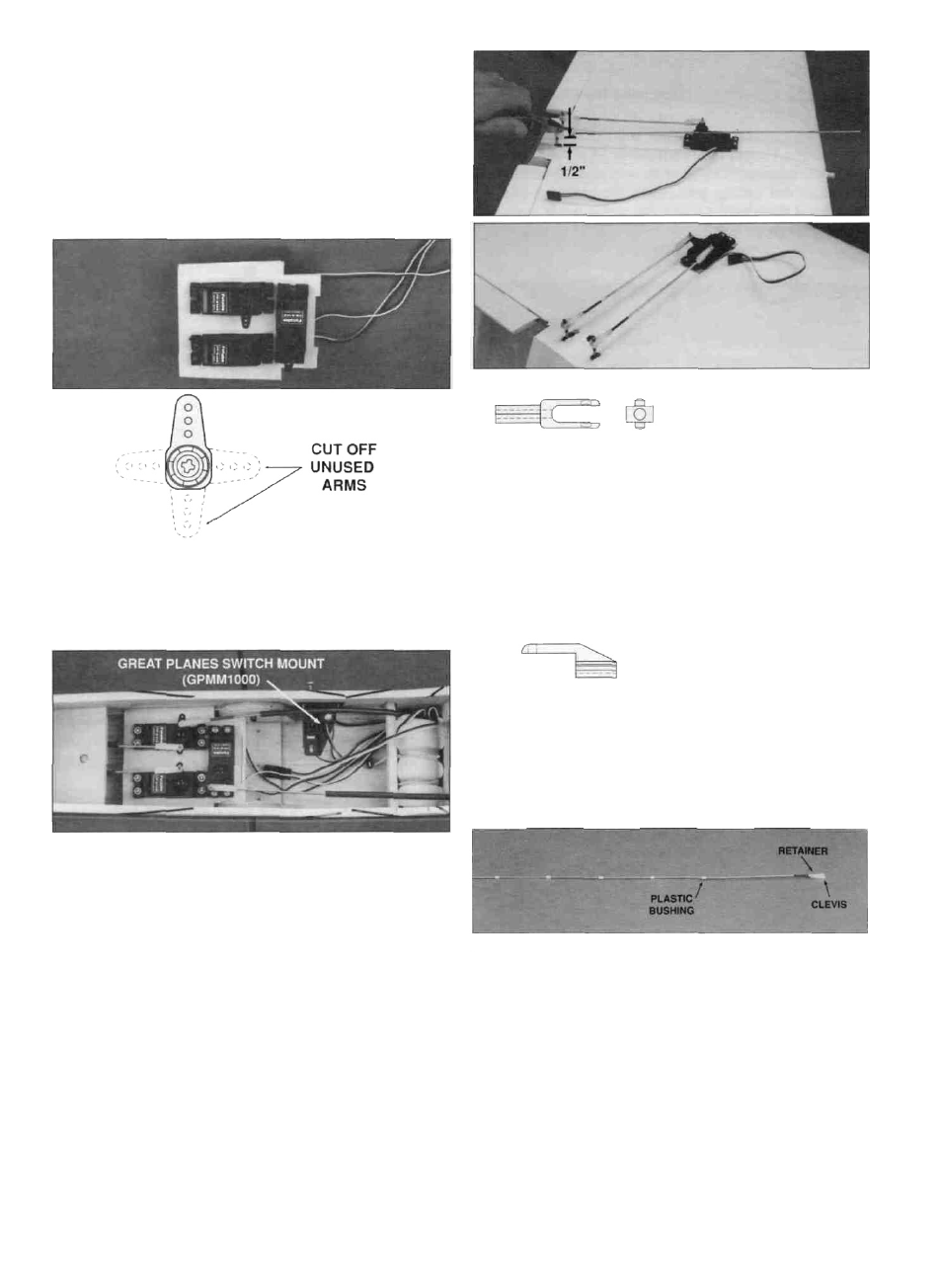

D 3 On the Easy Sport 40, glue the servo tray and the

die-cut 1/8" ply servo tray support (STS) securely in

place with medium or thick CA Add thick CA along the

joints to lock the tray in place

On the Easy Sport 60, do not glue the servo tray in

place at this time After the plane is covered and the

accessories are installed, the servo tray can be moved

forward or aft to adjust the balance point.

D 4 Mount the servos to the tray with the screws

included with your radio Attach the servo arms to the

servos with the hardware supplied with the radio You

may trim the servo arms to the shape required by the

particular application (study the photos)

D 5 Install the switch on the side opposite the engine

exhaust We added a Great Planes Switch Mount &

Charge Jack (GPMM1000) for convenience and ease of

use at the field Hook up the receiver and receiver

battery following the manufacturer's instructions Wrap

the receiver battery and receiver in 1/4" foam rubber,

then temporarily secure them in the fuselage After the

model has been balanced, use "popsicle sticks" or

leftover balsa glued between the fuse sides to

permanently hold the components in place Note The

compartment directly under the fuel tank has been

designed to house the battery in the event that nose

weight is needed for balancing Instead of adding weight

in the form of lead, try moving the battery to this location

during balancing.

Swivel Clevis & Swivel

D 6 Install the aileron servo as shown in the photo Make

sure the servo horn is toward the trailing edge Assemble

the swivel clevises then thread a 12" wire pushrod at least

13 revolutions onto each of them Thread the swivels onto

the torque rods until they are 1/2" (1/4" on the Easy Sport

60) above the trailing edge Cut off the excess threaded

torque rod wire or it may hit the wing mount plate when

the wing is mounted on the fuse.

Faslink™ Pushrod Keeper

D 7. Center the ailerons, then mark the pushrods at the

point where they meet the holes in the servo arm Make

a 90 degree bend in the wires Enlarge the servo horn

holes with a 5/64" drill bit Insert the bent wire pushrods

into the servo horn Then secure them with Faslink™

pushrod keepers and cut off the excess rod

D 8 Cut ten 3/16" bushings from the supplied 6-1/2"

inner plastic pushrod Slide five bushings onto two 36"

pushrods that are threaded at one end, spreading them

out as shown on the plan If the bushings are tight and

difficult to slide on, cut them to a shorter length Check

the fit on both pushrods making sure that the bushings

won't come out of the outer tube during operation If they

do, they could snag on the outer tube thereby

preventing control movement If needed, a small drop of

thin CA will hold the bushings in position.

45