Great Planes ESP6 Easy Sport 60 - GPMA0152 User Manual

Page 10

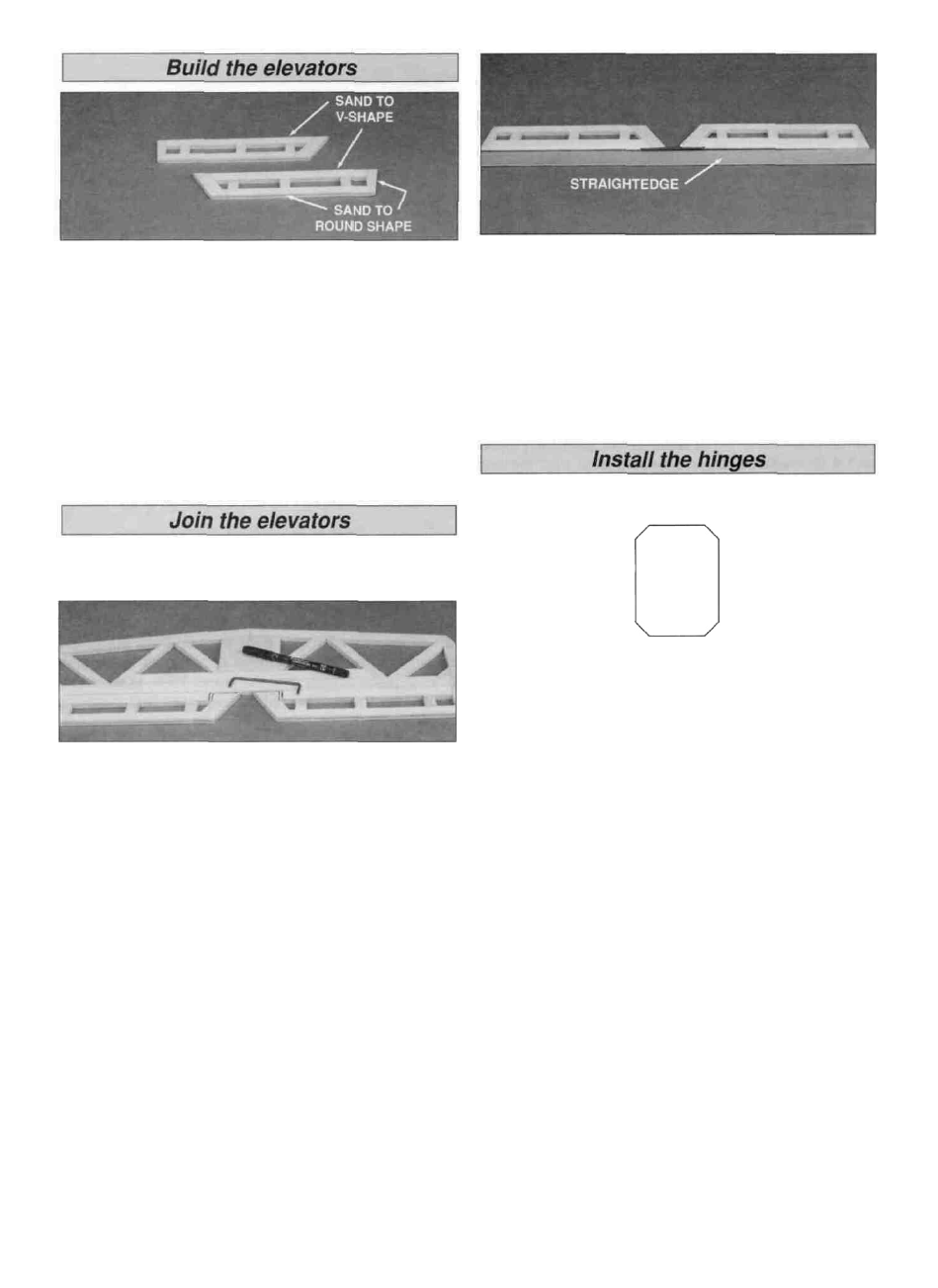

D 1 In the same manner as the rudder, build each

elevator using the 5/16" x 3/4" and 5/16" x 1/2"

balsa sticks

D 2. Shape the elevator tips to the shape as shown on

the plan.

D 3. Carefully draw a centerline all around the edges

of the elevators.

D 4. Sand the leading edge to a "V-shape Sand the

trailing edge and the outside edge of the tip to a round

shape as shown on the plans.

D 6 Trial fit the joiner wire into the elevators Then

glue it in using 6-minute or 30-mmute epoxy When

gluing, lay the elevators on a flat surface, with the

leading edges along a straightedge to insure perfect

alignment Cover the top of the joined elevators with a

sheet of waxed paper Then lay a flat, heavy object on

top A telephone book works well This will insure a true,

flat elevator assembly when the epoxy cures

(Do not glue)

D 1 Temporarily pin the elevators and stab over their

respective drawings on the plan

D 2. Lay the 1/8" wire elevator joiner in place on the

elevators and mark its outline using a fine point felt-tip pen

D 1. Cut 18 hinges (3/4" x 1") from the 2" x 9" CA hinge

strip Trim the corners at a 45 degree angle to make

insertion easier.

D 2 Lay the rudder and elevators on the plan and mark

the hinge locations. Place the rudder against the fin TE

and transfer the marks to the fin Place the elevators

against the stab TE and transfer the marks to the stab.

D 3 Accurately drill holes in the elevators for the 1/8"

wire joiner Begin by drilling a 1/16" or 5/64" pilot hole

Then drill the final hole to a depth of 7/8" with a 9/64"

drill bit (The hole is drilled slightly oversize to allow for

positioning, and to create a hard epoxy "sleeve" around

the wire)

D 4 Use the sharpened 1/8" diameter brass tube or a

drill bit to cut a groove in the leading edge of the

elevators to accept the joiner wire.

CAUTION: You must use extreme care when

cutting hinge slots with a hobby knife, to avoid

cutting yourself! If the balsa part breaks while you

are pushing on the knife, the blade could go into

your hand before you know it! A good precaution

is to wear leather gloves while performing the

following steps, and always cut away from

yourself.

D 5 Roughen the joiner wire with coarse sandpaper,

then clean the wire thoroughly with alcohol to remove

any oily residue.

D 3. Cut the hinge slots on the accurate centerlines

which you previously drew, using a hobby knife or a

slotting fork and slotting hook (The recommended hinge

slotting technique is explained on the next page.)

10