Great Planes ESP6 Easy Sport 60 - GPMA0152 User Manual

Page 40

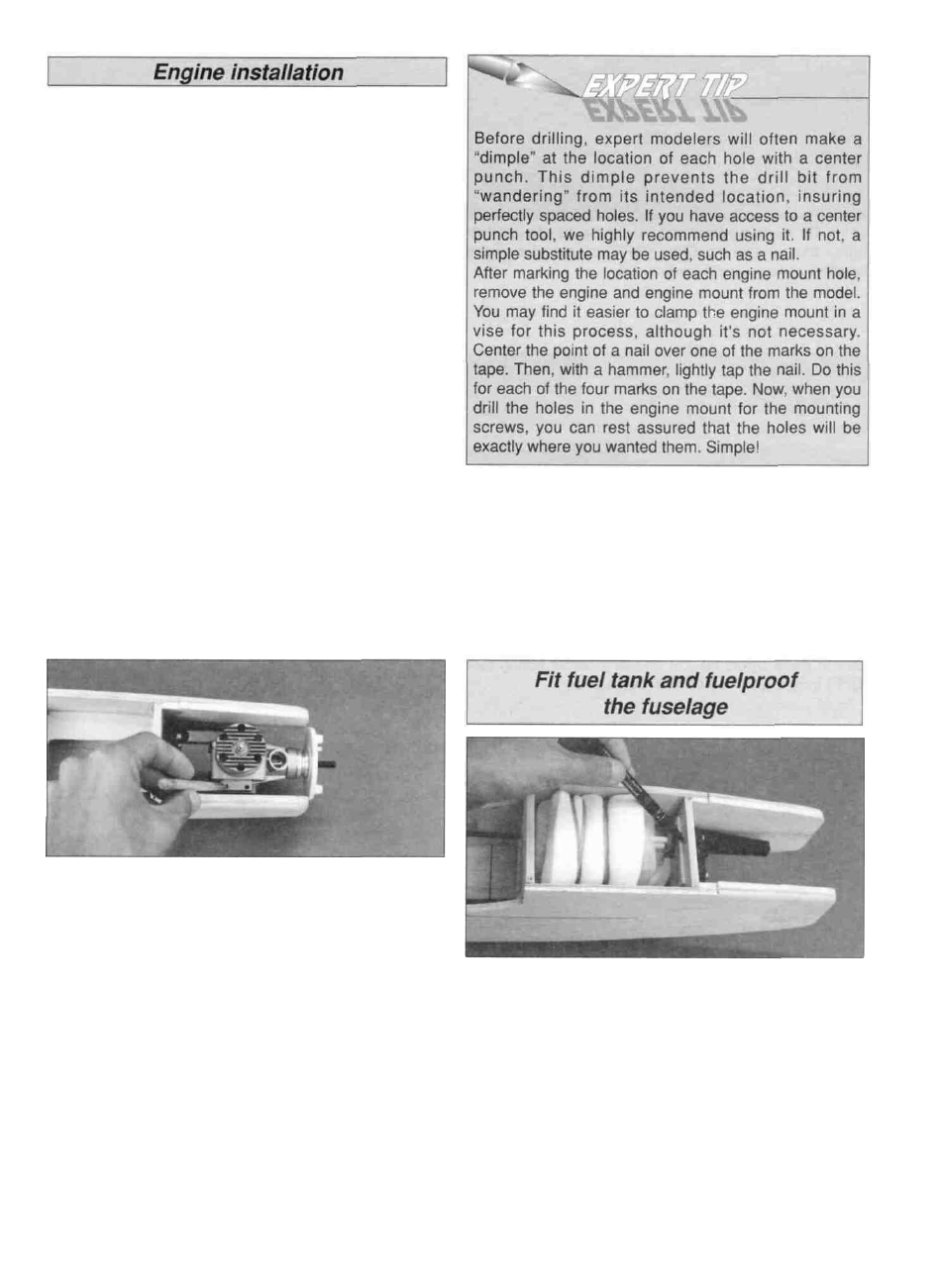

D 1. Cut off the spacer bar from each half of the engine

mount, and trim away any remaining bumps to permit

the mount halves to slide together

D 2. Fit the two halves of the mount together Remove

the muffler and carburetor from the engine and install

your spinner's backplate Test fit the engine to the

mount A d j u s t the width of the mounting rails to

accommodate the engine without binding or being too

loose (a couple of drops of thin CA may be used to tack

the two engine mount halves together) Remove the

engine. Use four #6 flat washers and four 6-32 x 3/4"

Phillips head screws (four #8 flat washers and four

8-32 x 1-1/4" socket head machine screws on the

Easy Sport 60) to attach the engine mount to the firewall

(do not tighten completely) Center the engine mount on

the f i r e w a l l using the embossed vertical line as

a reference

D 3. Tighten the mount screws so that you can mark the

engine screw holes without allowing the rails to move.

D 5 Remove the tape from the engine mount rails and

attach the engine to the rails using four #6 x 3/4" sheet

metal screws ( #8 x 1" sheet metal screws on the

Easy Sport 60) A drop of household oil on each screw

may help when initially installing the engine to the

engine mount Remove the engine from the mount

for now.

D 4. Place a length of masking tape on each rail of the

engine mount (the tape will allow you to see the pencil

marks) Position the engine forward or aft on the rails so

there is 4-7/8" between the firewall and the back of the

spinner backplate (6-1/4" on the Easy Sport 60) Use a

sharpened pencil to mark the four engine mounting

holes onto the tape Use a 7/64" drill bit (1/8" on the

Easy Sport 60) to drill pilot holes (see tip below) through

the rails for the #6 sheet metal screws (#8 sheet metal

screws on the Easy Sport 60) Note You must drill these

holes accurately, not allowing the drill bit to wander off

the mark The holes must also be perpendicular to the

rails The best way to achieve this is to use a drill press

If you do not have one, try to borrow a friend's.

D 1 Assemble your fuel tank according to the

manufacturer's instructions Wrap the fuel tank in latex

foam rubber and secure with #64 rubber bands (the

foam rubber shields the tank from engine vibration,

which can cause the fuel to foam) Fit the assembled

tank into the fuel tank compartment and mark the

location for the fuel and vent lines on the firewall

Remove the fuel tank and drill through the firewall at the

marks with a 15/64" drill

40