Great Planes ESP6 Easy Sport 60 - GPMA0152 User Manual

Page 22

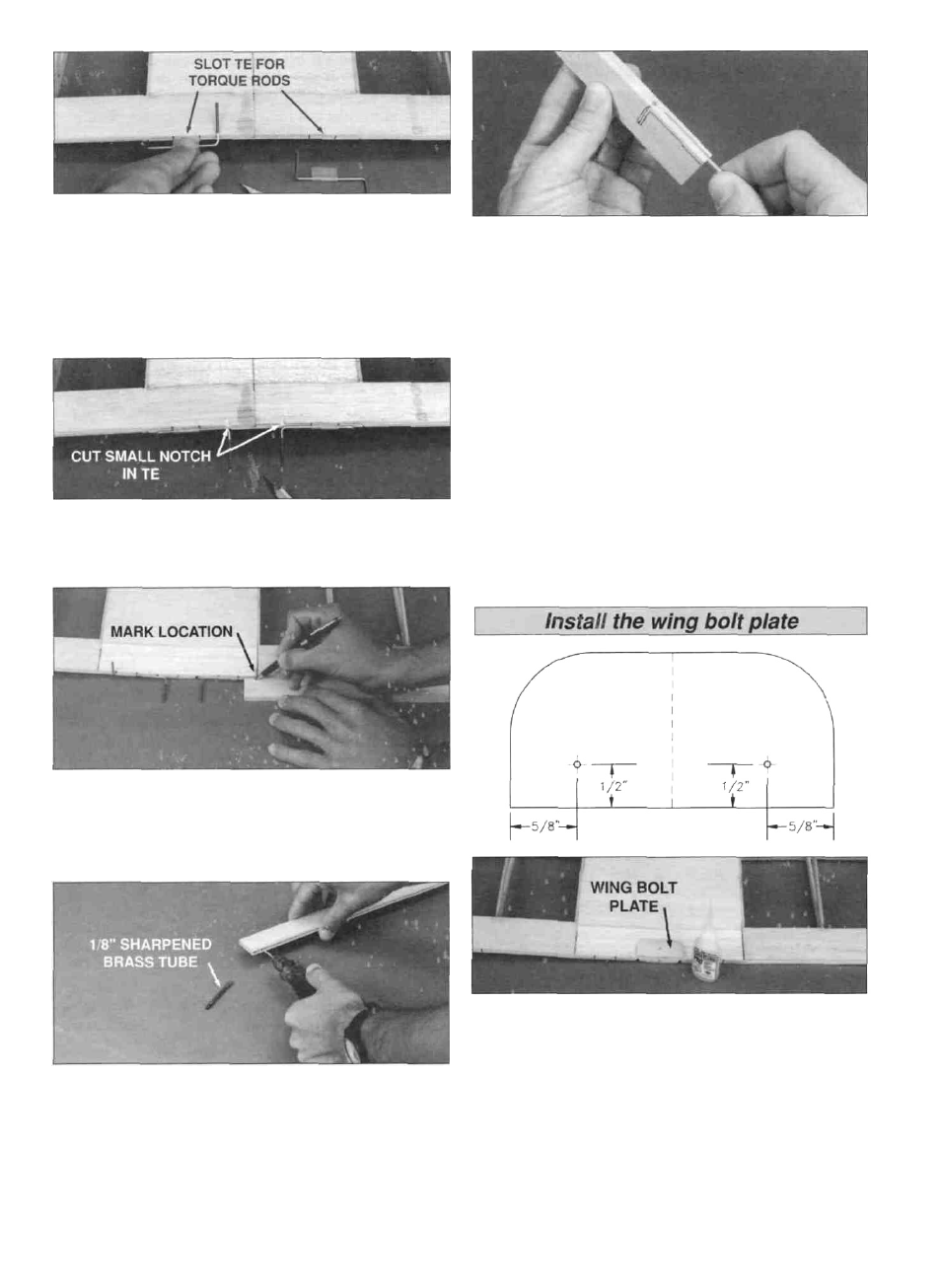

D 5. Align each wing half over its respective view on the

plans and mark the locations of the aileron torque rod

bearings and hinges. Using the same technique as

slotting for hinges, carefully slot the TE to accept the

aileron torque rod bearing in both wings. It helps to

have the torque rod handy for reference.

D 6. Cut small notches in the bottom of the TE to allow

the torque rod arms to swing forward.

D 9. Use the sharpened 1/8" diameter brass tube to cut

a groove in the leading edge of the ailerons to accept

the torque rods. Test fit the ailerons onto the torque rods

and cut as necessary until they fit.

D 10. Sand the LE of the ailerons to a "V" shape and

the TE of the ailerons to a rounded shape, as shown on

the plans.

D 11. Test fit the ailerons on the wing. Check for free

movement in both directions. There should be no

binding. Now is the time to locate any problems and

rectify them before the wing is covered and the ailerons

are permanently attached. A f t e r the ailerons are

checked, round the TE tips to match the ailerons.

D 12. Remove the ailerons, hinges and torque rods for

now. They'll be reinstalled later.

D 7. While holding the ailerons in place against the TE

(with the ends of the ailerons lined up with the TE tip),

mark the locations where the torque rods will enter

the ailerons.

D 8. Drill a 7/64" hole in each aileron to accept the

torque rod. Start at the leading edge centerline and drill

straight in to the proper depth.

Locate the die-cut 1/8" ply wing bolt plate (WB) and,

with medium CA, glue it to the top center TE of the wing

as shown on the plans. Make sure that (WB) is centered

on the TE and securely glued in place. On the Easy

Sport 40, the punch mark must face up so that you can

use it later. On the Easy Sport 60, place two marks at

the locations shown on the drawing above.

22