Innovation series water heaters gf-128 – AERCO Innovation (G-10-1350 to G-11-0563) User Manual

Page 83

Chapter 7

Innovation Series Water Heaters

GF-128

Troubleshooting Guide

USER MANUAL

OMM-0079_0B

PR1 - 07/21/11

AERCO International, Inc.

· 100 Oritani Dr. · Blauvelt, NY 10913 · Ph: 800-526-0288

Page 83 of 200

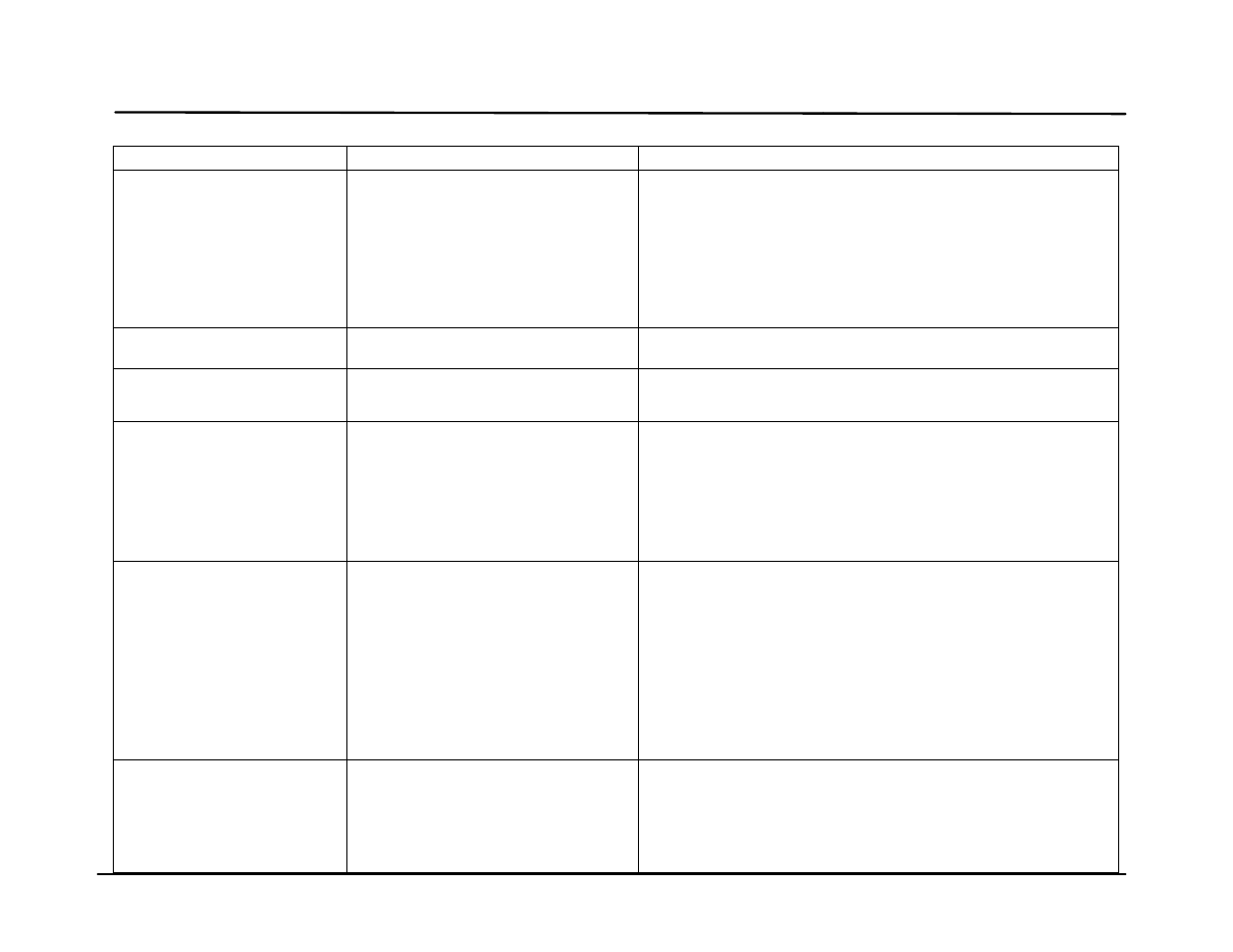

TABLE 7-1. WATER HEATER TROUBLESHOOTING – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

RESIDUAL

FLAME

1. SSOV not fully closed.

2. Defective Flame Detector

1. Check open/close indicator window of Safety Shut-Off Valve

(SSOV) and ensure that the SSOV is fully closed. If not fully

closed, replace the valve and or actuator.

Close the 1” Gas Shut-Off Valve downstream of SSOV (Figure

7-1). Install a manometer or gauge at the leak detection port

between the SSOV and Gas Shut Off Valve. If a gas pressure

reading is observed replace the SSOV Valve and/or Actuator.

2. Replace Flame Detector.

SSOV FAULT DURING

PURGE

See SSOV SWITCH OPEN

SSOV FAULT

DURING RUN

SSOV switch closed for 15 seconds

during run.

1. Replace or adjust microswitch in SSOV actuator. If fault

persists, replace actuator.

SSOV RELAY

FAILURE

1. SSOV relay failed on IGST board.

2. Floating Neutral.

3. Hot and Neutral reversed at SSOV.

1. Press CLEAR button and restart unit. If fault persists, replace

Ignition/Stepper (IGST) Board.

2. The Neutral and Earth Ground are not connected at the source

and therefore there is a voltage measured between the two.

Normally this measurement should be near zero or no more than

a few millivolts.

3. Check SSOV power wiring.

SSOV

SWITCH OPEN

1. Actuator not allowing for full closure

of gas valve

2. SSOV powered when it should not

be

3. Defective Switch or Actuator

4. Incorrectly wired switch.

1. Observe operation of the Safety Shut-Off Valve (SSOV) through

indicator on the Valve actuator and ensure that the valve is fully

and not partially closing.

2. If the SSOV never closes, it may be powered continuously.

Close the gas supply and remove power from the unit. Refer

fault to qualified service personnel.

3. Remove the electrical cover from the SSOV and check switch

continuity. If the switch does not show continuity with the gas

valve closed, either adjust or replace the switch or actuator.

4. Ensure that the SSOV Proof of Closure switch is correctly wired.

STEPPER MOTOR

FAILURE

1. Air/Fuel Valve out of calibration.

1. Perform Stepper Test per GF-112 (para. 6.3.5) to ensure

stepper motor rotates properly from 0% (fully closed) to 100%

(fully open) positions. Verify VALVE POSITION bargraph and

dial on the Air/Fuel Valve track each other to indicate proper

operation. If operation is not correct, perform the Stepper

Feedback Calibration (GF-112, para. 6.2.1).