Gf-5080 – AERCO Innovation (G-10-1350 to G-11-0563) User Manual

Page 188

Page 188 of 200

AERCO International, Inc.

· 100 Oritani Dr. · Blauvelt, NY 10913 · Ph.: 800-526-0288 07/21/11

GF-5080

TAG-0046 0A

Commercial Laundry Sizing Guide

Storage Tank size in gallons

=

2GPH • machine capacity in pounds

3 • 0.7

SIZING THE CIRCULATOR

Select the required pump flow rate from Chart B below, based on desired system set point and number of Innovation

units selected. Head loss depends on loop piping.

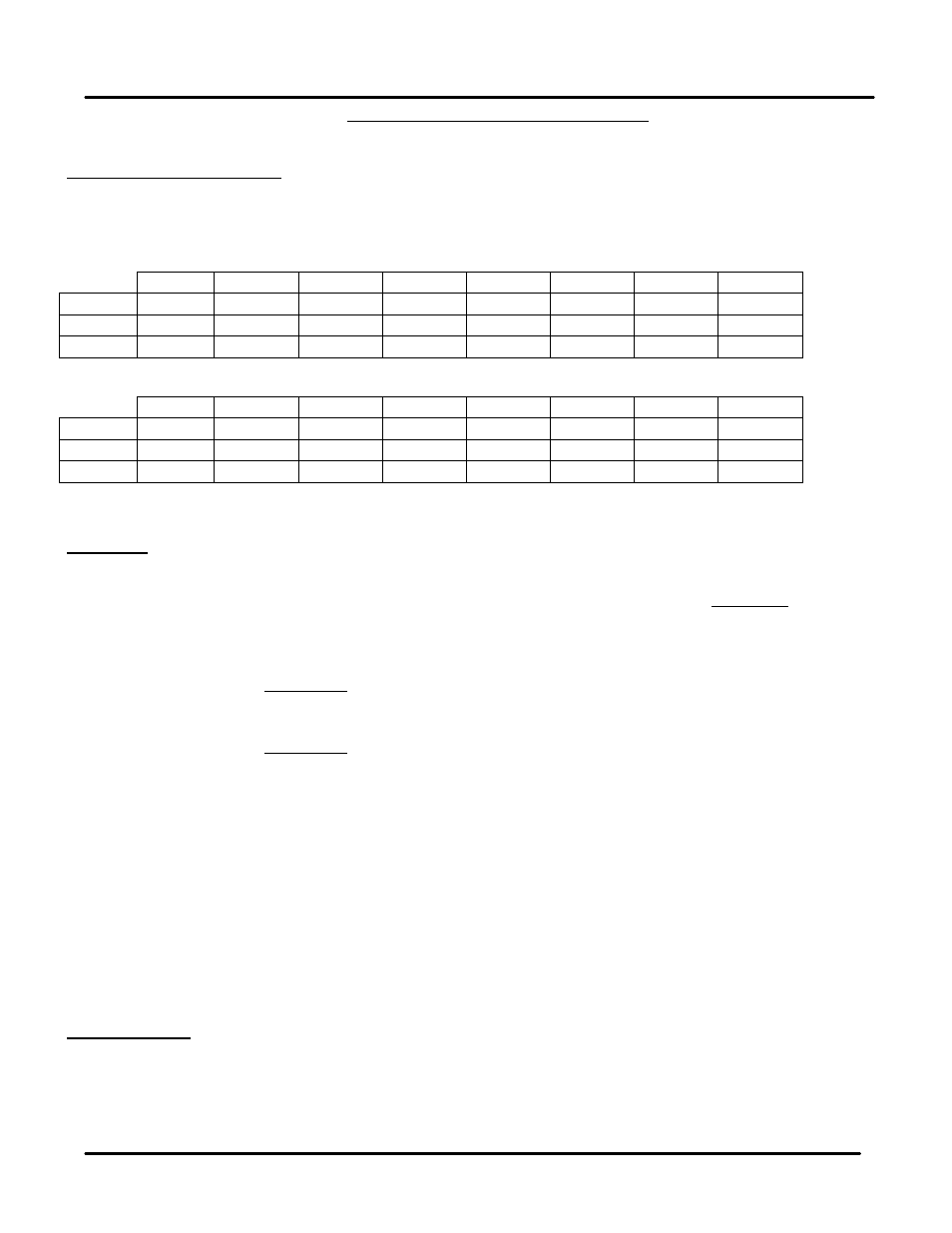

Chart A - Heater Selection (GPM)

(1) 600

(1) 800

(1) 1060

(2) 600

(2) 800

(2) 1060

(3) 800

(3) 1060

40 - 140

11

15

20

22

30

40

45

60

40 - 160

10

13

17

20

26

34

39

51

40 - 180

8

11

14

16

22

28

33

42

Chart B - Circulator Selection (GPM)

(1) 600

(1) 800

(1) 1060

(2) 600

(2) 800

(2) 1060

(3) 800

(3) 1060

40 - 140

11

15

20

22

30

40

45

60

40 - 160

10

13

17

20

26

34

39

51

40 - 180

8

11

14

16

22

28

33

42

If recovery rate is less than or equal to capacities shown above, select that number of Innovation water heaters.

EXAMPLE: Given washer capacities of:

1

400#

With a required temperature rise of 40°F – 160°F

1

200#

1

100#

1

75#

Total= 775#

AHHWR

=

2 • 775#

=

1550

Heater Capacity

=

2 • 775#

=

26 GPM; from Chart A: 2 INN800’s

60

Tank Capacity

=

2 • 775#

=

738 gallons

3 • 0.7

Circulator Capacity

=

26 GPM, from Chart B

DETERMINATION OF MAXIMUM INSTANTANEOUS DEMAND (MID)

The nominal machine cycle of 45 to 50 minutes, exclusive of loading and unloading, is generally based on a 50 to 60

second time to fill to high fill level. Many machine manufacturers are currently recommending a 30 second fill time to fill

to high level. While fill time has no impact on tank and circulator sizes, and none on heater capacity, it does impact line

sizes and dictates the maximum surge flow through the nozzles which must be accommodated. Therefore, it is

essential to be able to determine this flow for various “fill” times.

The factors used in the following examples are machine manufacturer’s recommended factors to account for diversity

resulting from a varying number of machines and variations in machine sizes.

2-minute fill time

1 or 2 machines:

MID = 0.15GPM • capacity of largest machine in pounds

3 or more machines:

MID = 0.15GPM • capacity of largest machines in pounds PLUS

0.10GPM • total capacity of all other machines in pounds

Pg. 4 of 10