Innovation series water heaters – AERCO Innovation (G-10-1350 to G-11-0563) User Manual

Page 82

GF

-

128

Innovation Series Water Heaters

Chapter 7

OMM-0079_0B

USER MANUAL

Troubleshooting Guide

Page 82 of 200

AERCO International, Inc.

· 100 Oritani Dr. · Blauvelt, NY 10913 · Phone: 800-526-0288

PR1 - 07/21/11

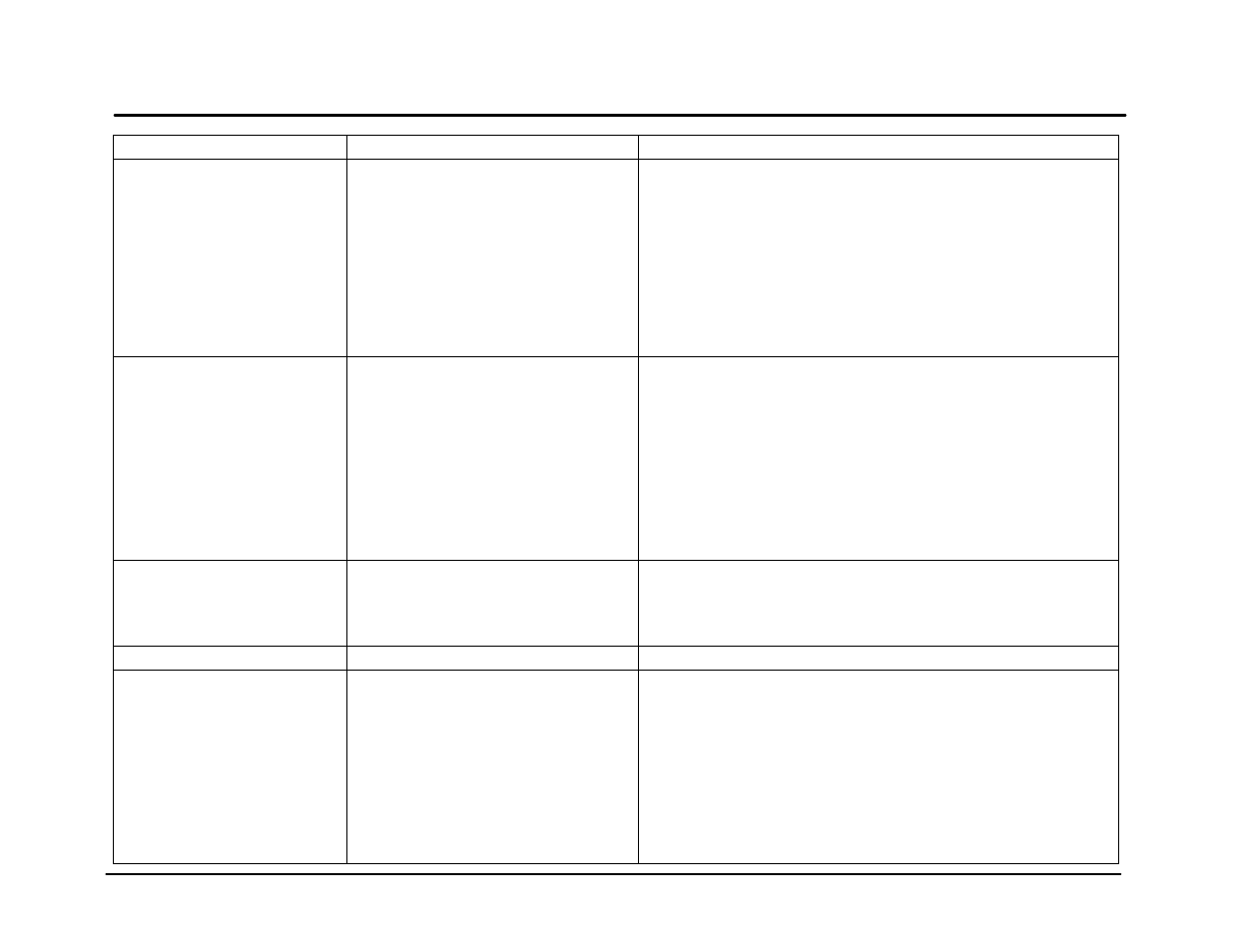

TABLE 7-1. WATER HEATER TROUBLESHOOTING – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

(continued)

2. Defective or shorted switch.

3. Switch wired incorrectly.

4. Defective Power Supply Board or

fuse

5. Defective IGST Board

2. If the Air/Fuel Valve does rotate to the ignition position, check

the purge switch for continuity between the N.O. and COM

terminals. If the switch shows continuity when not in contact

with the cam, check to ensure that the switch is wired correctly

(correct wire numbers on the normally open terminals).

3. If the switch is wired correctly, replace the switch.

4. Check DS1 & DS2 LEDs on Power Supply Board. If they are not

steady ON, replace Power Supply Board.

5. Check “Heartbeat” LED DS1 and verify it is blinking ON & OFF

every second. If not, replace IGST Board.

PRG SWTCH OPEN

DURING PURGE

1. Defective purge switch.

2. No voltage present at switch.

3. Switch wired incorrectly.

4. Defective Power Supply Board or

fuse

5. Defective IGST Board

1. If the air-fuel valve does rotate, check purge switch for continuity

when closing. Replace switch if continuity does not exist.

2. Measure for 24 VAC from each side of the switch to ground. If

24VAC is not present, refer fault to qualified service personnel.

3. Check to ensure that the switch is wired correctly (correct wire

numbers on the normally open terminals).

4. Check DS1 & DS2 LEDs on Power Supply Board. If they are not

steady ON, replace Power Supply Board.

5. Check “Heartbeat” LED DS1 and verify it is blinking ON & OFF

every second. If not, replace IGST Board.

OUTDOOR TEMP

SENSOR FAULT

1. Loose or broken wiring.

2. Defective Sensor.

3. Incorrect Sensor.

1. Inspect Outdoor Temperature sensor for loose or broken wiring.

2. Check resistance of sensor to determine if it is within

specification.

3. Ensure that the correct sensor is installed.

RECIRC PUMP FAILURE

1. Internal recirculation pump failed.

1. Replace recirculation pump.

REMOTE SETPT

SIGNAL FAULT

1. Remote setpoint signal not present:

Not yet installed.

Wrong polarity.

Signal defective at source.

Broken or loose wiring.

2. Signal is not isolated (floating) if 4 to

20 mA.

3. Control Box signal type selection

switches not set for correct signal

type (voltage or current).

1. Check I/O Box to ensure signal is hooked up.

Hook up if not installed.

If installed, check polarity.

Measure signal level.

Check continuity of wiring between source and unit.

2. Check signal at source to ensure it is isolated.

3. Check DIP switch on PMC board to ensure it is set correctly for

the type of signal being sent. Check control signal type set in

Configuration Menu.