Cub Cadet Yanmar 3TNV72 User Manual

Page 152

ENGINE

TNV IDI Service Manual

6-53

Cylinder Block

Inspection of Camshaft Bushing and Bores

1. Measure the I.D. of the front bushing and the

remaining bores in the cylinder block. Record

the measurements. See Camshaft on page 6-7

for specifications.

If the camshaft bushing is not within specification,

replace using the appropriate service tool. If the

remaining bores are not within specification, the

cylinder block will require replacement as there are

no bearing inserts used.

Inspection of Idler Gear and Shaft

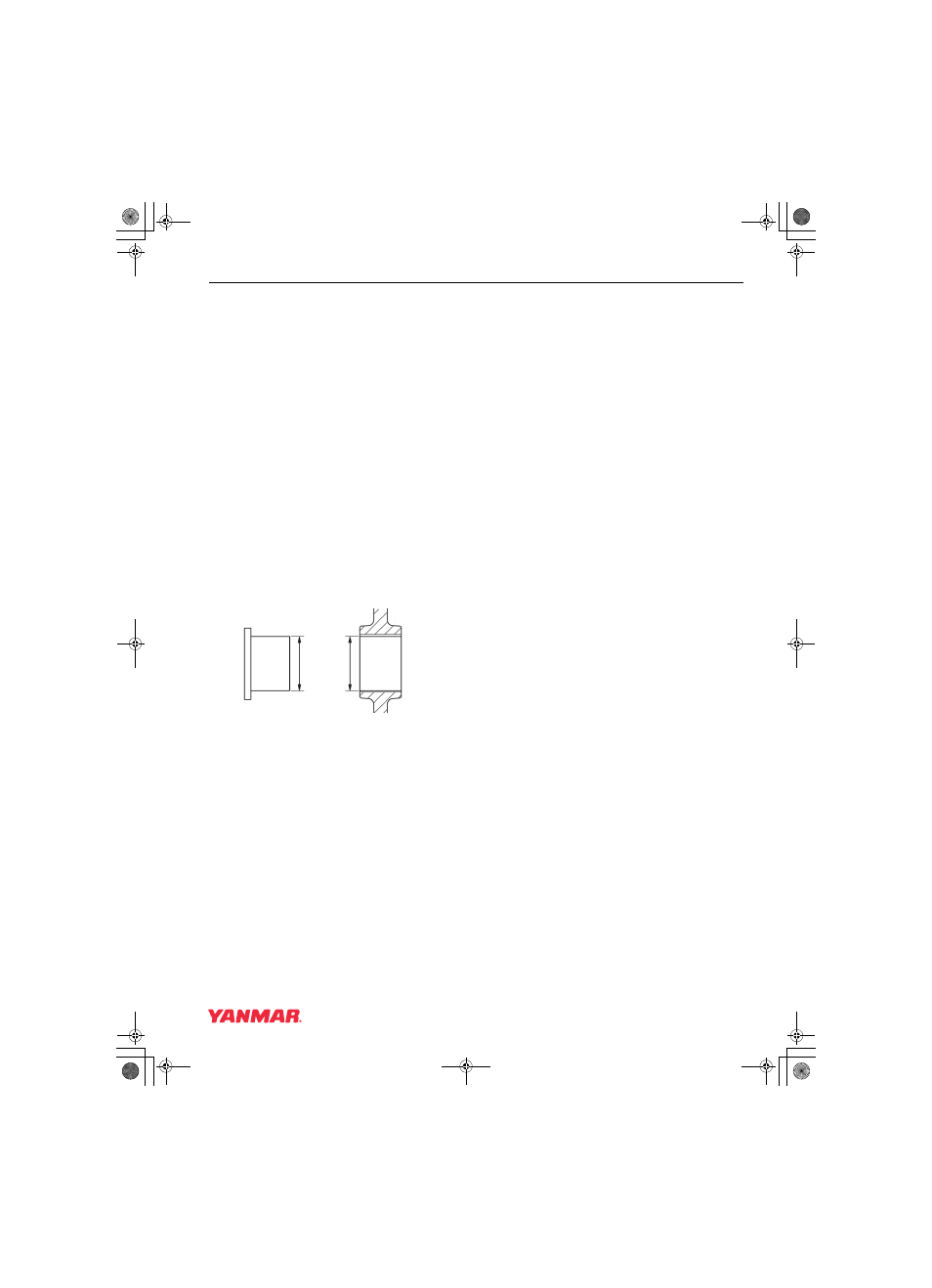

1. Measure the outside diameter

(Figure 6-80, (1)) of the idler gear shaft

(Figure 6-80, (2)). Record the measurements.

See Idler Gear Shaft and Bushing on page 6-8

for specifications.

2. Measure the inside diameter (Figure 6-80, (3))

of the idler gear bushing (Figure 6-80, (4)).

Record the measurements. See Idler Gear

Shaft and Bushing on page 6-8 for

specifications.

Figure 6-80

Honing and Boring

Pistons must move freely in the cylinders while

maintaining adequate compression and oil sealing.

If the cylinder walls are scuffed, scored,

out-of-round, or tapered beyond specifications,

rebore and hone to restore cylinders to usable

condition. Slight imperfections can be corrected by

honing alone.

1. Boring - Significant cylinder damage may be

corrected by boring the cylinder to an oversize

dimension. Refer to the appropriate parts

catalog for available oversize pistons and piston

rings.

• Boring a cylinder should always be done in a

properly equipped machine shop.

• A bored cylinder should always be finished with

a hone to properly prepare the cylinder surface

so the new piston rings will seat properly.

• After the cylinder has been bored and honed,

install the appropriate oversize pistons and

piston rings.

2. Honing - Minor cylinder imperfections may be

corrected by using a rigid cylinder hone

(Figure 6-82, (1)). Be sure not to exceed the

maximum cylinder bore specification.

Deglazing - A used cylinder that did not require

boring or honing, should always be deglazed with

a ball hone (Figure 6-82, (2)) before installing

new piston rings. This will properly prepare the

cylinder surface to allow new piston rings to seat

properly.

Note: When honing a cylinder, with either a

ridged hone or a ball hone

(Figure 6-81, (1)), move the rotating

hone up and down in the cylinder bore to

accomplish a 30° to 40° crosshatch

pattern (Figure 6-81). This will provide

the ideal surface for the proper seating of

new piston rings.

(1)

(3)

(4)

(2)

TNV_IDI_ServiceManual_(3TNV72 for YN only).book 53 ページ 2007年11月29日 木曜日 午後2時58分