Cub Cadet Yanmar 3TNV72 User Manual

Page 124

ENGINE

TNV IDI Service Manual

6-25

Cylinder Head

Cleaning of Cylinder Head

Components

Thoroughly clean all components using a

non-metallic brush and an appropriate solvent.

Each part must be free of carbon, metal filings and

other debris.

Inspection of Cylinder Head

Components

Visually inspect the parts. Replace any parts that

are obviously discolored, heavily pitted or otherwise

damaged. Discard any parts that do not meet its

specified limits.

IMPORTANT

Mark all valve train components so they can

be installed in their original locations.

Note: Record all measurements taken during

inspection.

Inspection of Push Rods

Push Rod Bend

Determine if the bend of the push rods is within the

specified limit.

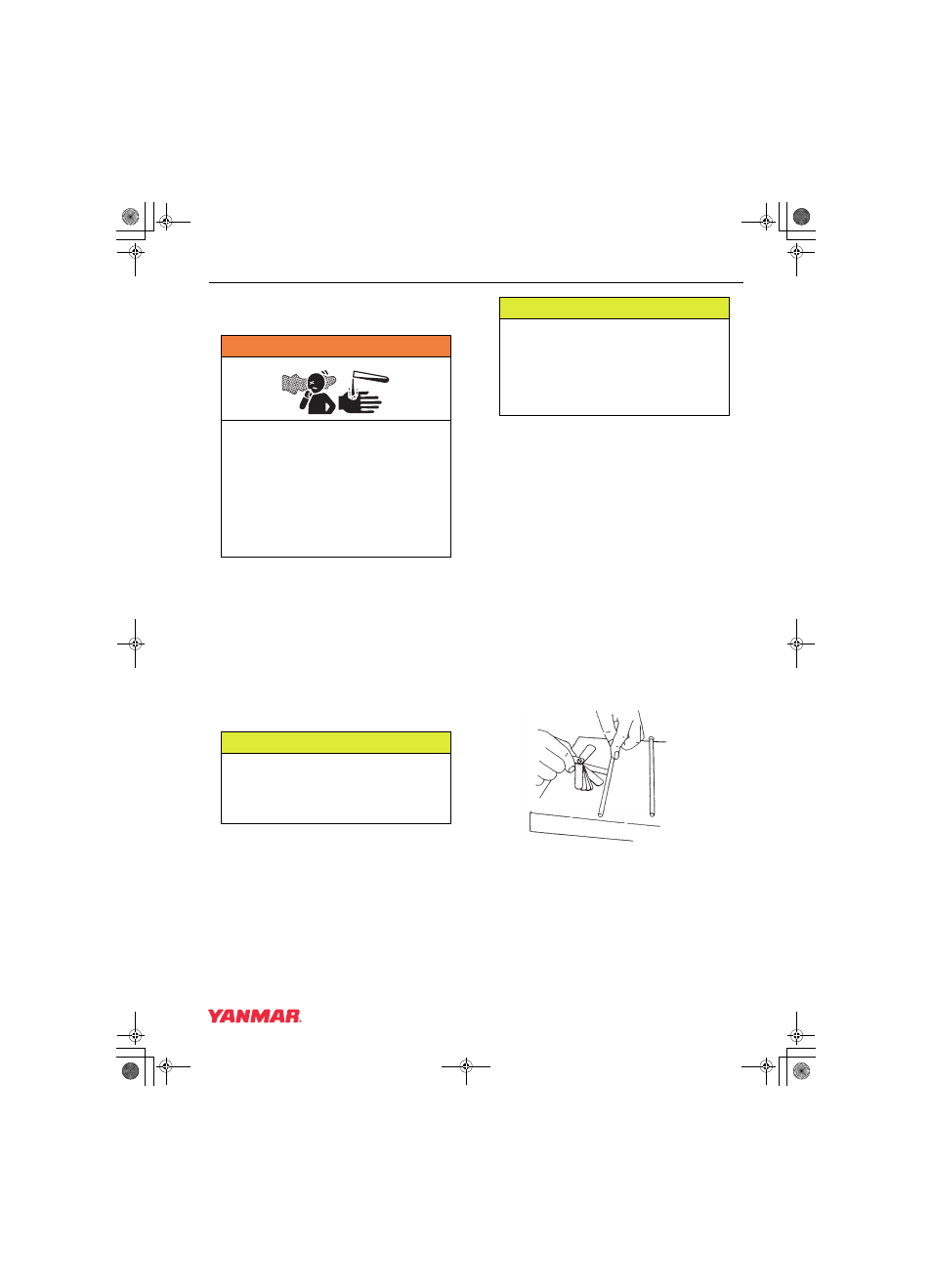

1. Place the push rods on a flat inspection block or

layout bed.

2. Roll the push rods until a gap can be observed

between a portion of the push rod and the

surface of the block or layout bed.

3. Use a feeler gauge to measure the gap

(Figure 6-11). See Push Rod on page 6-6 for

the service limit.

Figure 6-11

A

WARNING

FUME / BURN HAZARD!

• Always read and follow safety related

precautions found on containers of

hazardous substances like parts

cleaners, primers, sealants and

sealant removers.

• Failure to comply could result in death

or serious injury.

0000014en

CAUTION

Any part which is found defective as a

result of inspection or any part whose

measured value does not satisfy the

standard or limit must be replaced.

0000119en

CAUTION

Any part determined to not meet the

service standard or limit before the next

service, as determined from the state of

current rate of wear, should be replaced

even though the part currently meets the

service standard limit.

0000120en

0000204

TNV_IDI_ServiceManual_(3TNV72 for YN only).book 25 ページ 2007年11月29日 木曜日 午後2時58分