Series 5500 xtherm – EFCO 5500X Outside Glazed User Manual

Page 45

EFCO 2012

Page 45

Series 5500 XTherm

™

Curtain Wall Assembly and Installation Instructions

Note: Care should be

taken when handling

the frames to avoid

damaging the edges

of the fillers. Blocks

of wood used with

“C” clamps should be

employed to aid in

snapping together the

filler and the

mullions.

Apply joint plugs into the

open areas adjacent to the

horizontals as shown in

Section 8, starting on page 29.

NOTE: On long runs,

check overall frame

dimensions at every

fifth opening to avoid

dimensional build-up.

The commercial cut

length tolerance is +/-

1/16”. It is critical to

check every fifth unit

for location relative to

established

benchmarks.

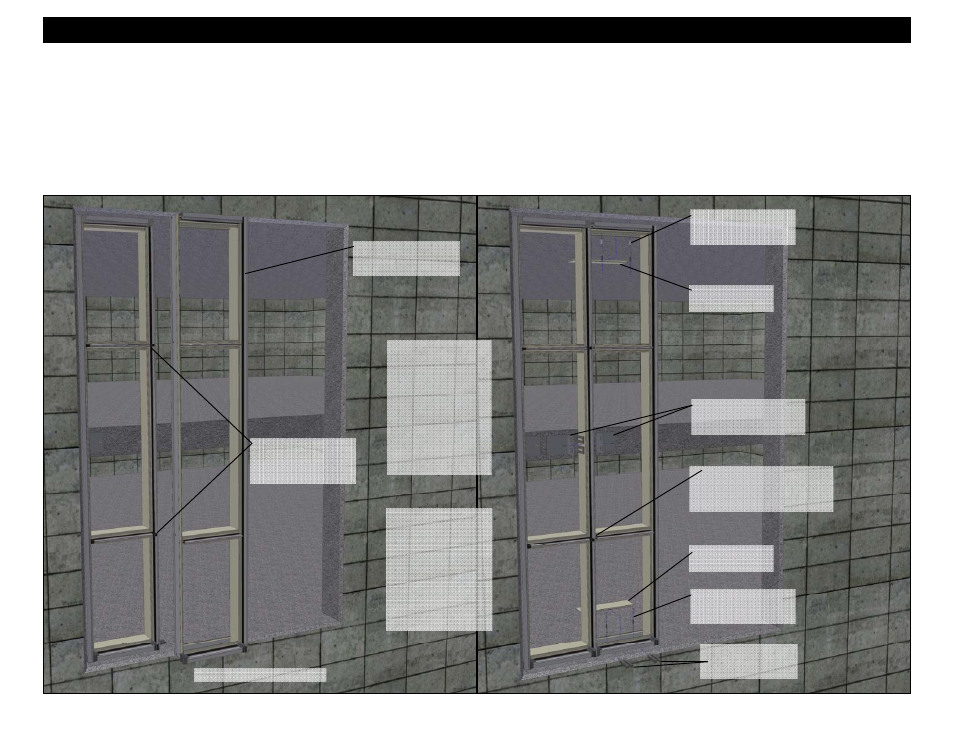

Section 12 - Install Twin Span Frame Components

Typical Intermediate Frame

Set the frame into the

opening and shim

level and plumb.

Snap fillers in to

head and sill.

Seal the vertical at all

horizontal locations.

(See Figure 2 and 3

on page 17).

Snap fillers in to

head and sill.

Anchor the frame into

the opening as shown

on pages 33 and 34.

Anchor the frame into

the opening as shown

on pages 33 and 34.

Apply intermediate wind

load anchors. See

pages 46 through 47.

Apply dead load

shims at anchors

and below verticals

13. Apply sealant to the verticals as shown in Figures 2 and 3 on page 17 to seal the vertical and fillers at the intersection of the heads, sills, and intermediate

horizontals. This seal should be made immediately before snapping the filler and the vertical mullions together.

14. Set the intermediate frame into the opening mating the filler with the intermediate vertical until the filler and vertical snap together.

15. Use dead load shims at the sill to level the frame, and make all necessary adjustments to properly locate the frame to established benchmarks.

16. After the frame is plumb and all adjustments have been made, match drill through the holes in the head and sill into the surrounding substrate, and apply the

anchor bolts at the head and sill. Anchor bolt size, type, quantity, and location vary. Refer to the final approved shop drawings for more information. The

anchors at the head require an anchor bolt sleeve to accommodate thermal expansion and contraction, and building movements.

17. Apply intermediate wind load anchors as shown and noted on pages 46 and 47.