Series 5500 xtherm – EFCO 5500X Outside Glazed User Manual

Page 33

EFCO 2012

Page 33

Series 5500 XTherm

™

Curtain Wall Assembly and Installation Instructions

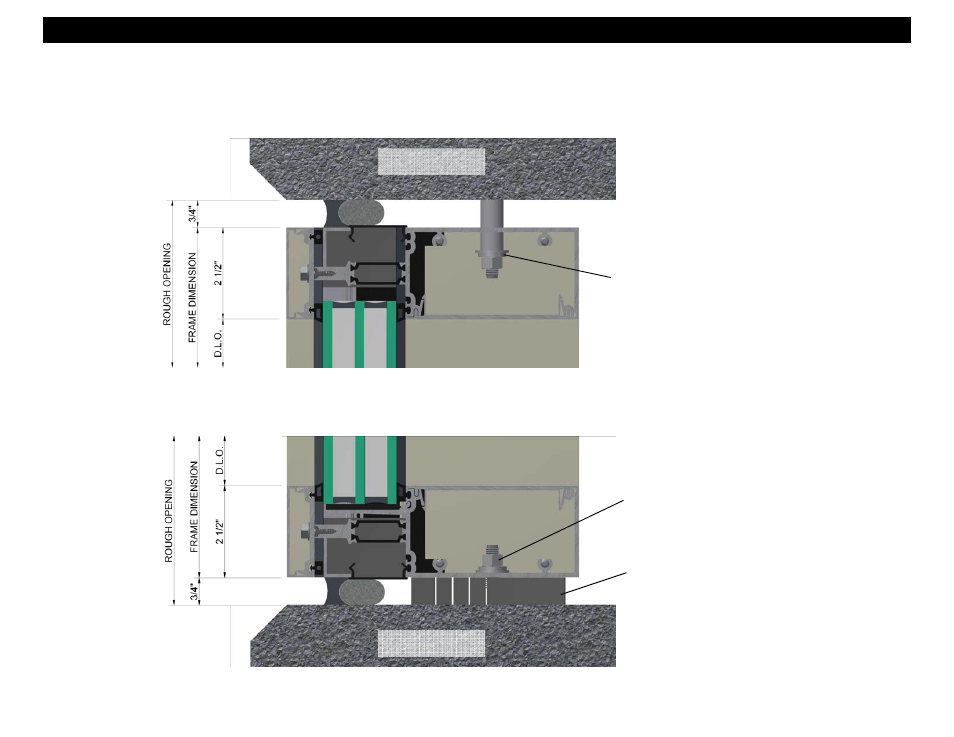

Section 10 - Standard Anchorage Method

Refer to the approved shop drawings for job specific conditions, anchor type, anchor bolt sizes, and locations. Install anchor assemblies according to the

final approved shop drawings. The anchor type used must be selected based on the structural requirements and the substrate.

Note:

See alternate anchorage details for head

conditions attaching to wood, light gauge

metal studs, or high load reactions.

Masonry or heavy

gauge steel condition.

Masonry or heavy

gauge steel condition.

Note: It is up to the responsible engineer to determine

the structural adequacy and type of anchorage method

to be used for a given substrate, applied loads, and

building movements. The S-5500 has different anchorage

options available to meet these conditions.

Anchor Bolts and Sleeve Anchor (Type and quantity as

required by conditions and loads, See shop drawings).

Anchor Bolts (Type and quantity as required by

conditions and loads, See shop Drawings)

Shim as required at anchors and

under each vertical mullion. (Shim

under setting blocks at heavy lites.)

Standard Head And Sill Anchorage

Note: The maximum reaction load for the Series 5500 XTherm

screw spline system is 1600 lbs. at the head and at the sill of

intermediate vertical anchor locations, and 800 lbs. at the head

and sill of jamb anchor locations. For higher reaction loads,

use mullion 'F' and 'M' anchors with drop on heads and sills.