Carrier 16DF013-050 User Manual

Page 8

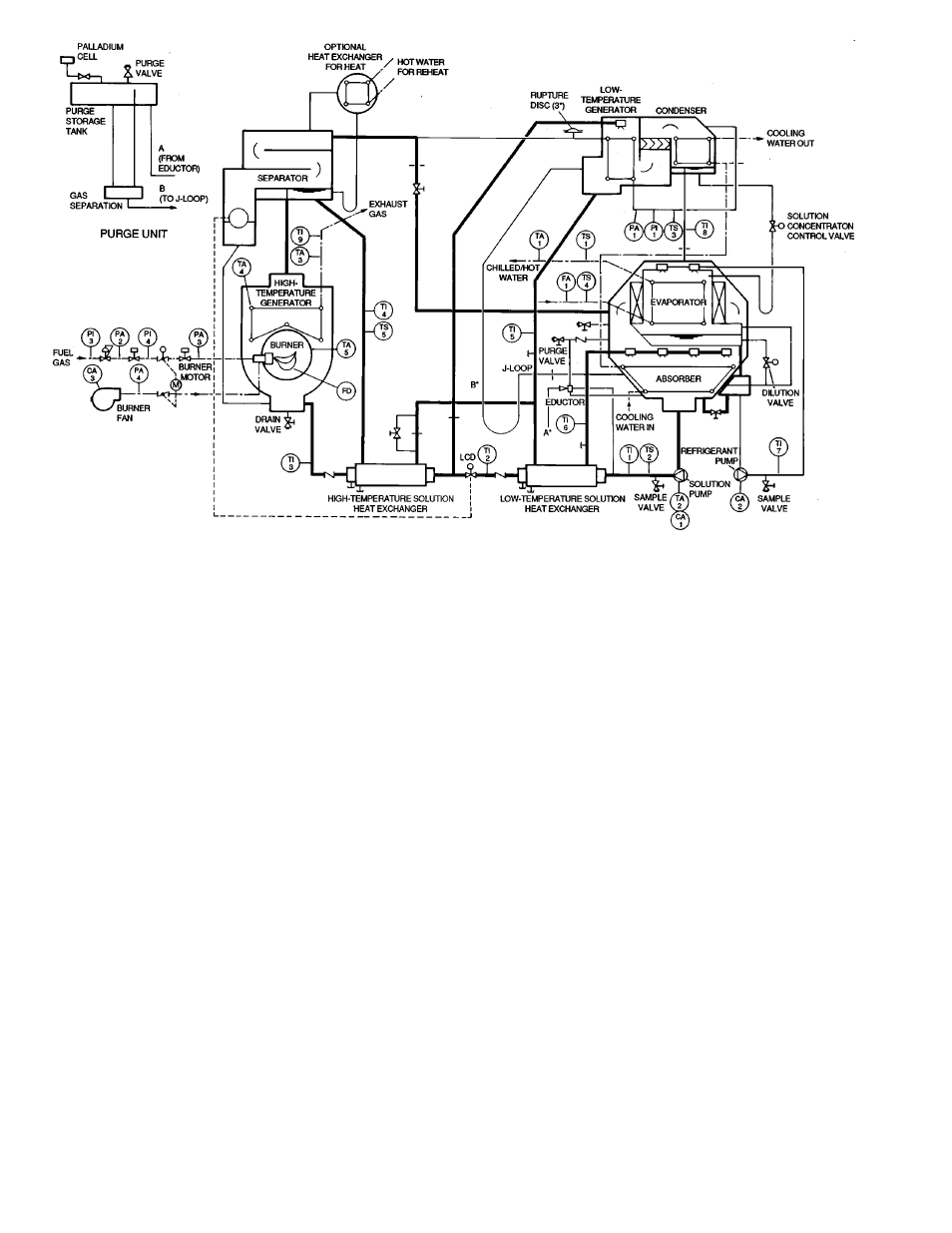

LEGEND

A,B

— Connecting Piping from Purge

Unit Diagram to Machine Cycle

Diagram

CA1 — Solution Pump Motor Overload

CA2 — Refrigerant Pump Motor Overload

CA3 — Burner Blower Motor Overload

FA1

— Chilled/Hot Water Flow Switch

FD

— Burner Flame Detector

LCD — Level Control Device

M

— Burner Firing Rate Positioning

Motor

PA1

— High-Temperature Generator High-

Pressure Switch

PA2

— Low Gas Pressure Switch

PA3

— High Gas Pressure Switch

PA4

— Low Combustion Air Pressure

Switch

PI1

— High-Temperature Generator

Pressure Gage

PI3

— Supply Gas Pressure Gage

PI4

— Regulated Gas Pressure Gage

TA1

— Chilled/Hot Water Temperature Limit

TA2

— Solution Pump Motor High-

Temperature Limit

TA3

— Exhaust Gas High-Temperature

Limit

TA4

— Fire Tube High-Temperature Limit

TA5

— Return End Refractory

High-Temperature Limit

TI1-3 — Weak Solution Temperature

Measurement Wells

TI4-6 — Strong Solution Temperature

Measurement Wells

TI7

— Refrigerant Temperature

Measurement Well

TI8

— Refrigerant Condensate Tempera-

ture Measurement Well

TI9

— Exhaust Gas Temperature

Measurement Gage

TS1 — Leaving Chilled/Hot Water

Temperature Sensor

TS2 — Weak Solution Temperature

Sensor

TS3 — High-Temperature Generator

Vapor Temperature Sensor

TS4 — Entering Chilled/Hot Water

Temperature Sensor

TS5 — High-Temperature Generator

Strong Solution Temperature

Sensor

*See Purge Unit insert.

NOTE: Service valve connections are

1

⁄

2

-in. NPT.

Fig. 6 — Heating Cycle with Data Points

8