Carrier 16DF013-050 User Manual

Page 25

Typical Control Sequence — Normal Cooling

Start (Fig. 24)

1. When power is supplied to the chiller control panel and

the machine is not in operation, the status indicator will

display ‘‘000’’.

2. For starting, the machine and burner switches should be

positioned as shown in Table 8, and the manual cooling/

heating valves positioned for cooling (Table 9).

NOTE: The Cool switch selection must be made before

the Start button is depressed.

3. When the Start button is depressed, the microprocessor

will initiate the timed starting and system checks se-

quence. The chilled water pump will be started, if not al-

ready running. After 20 seconds, the pump run interlock(s)

will be checked to verify if the pump is running. If it is,

the status indicator will display ‘‘CPO’’. If not, the se-

quence will be halted until the interlocks show the pump

is running.

4. The capacity controller then will be queried to see if there

is a need for cooling. If not, the sequence will be halted.

If cooling is required, the cooling water pump will be started,

if not already running. After 20 seconds, the pump run

interlock(s) will be checked to verify it is running. If it is,

the start sequence will proceed. If not, the sequence will

be halted until the interlocks show the pump is running.

When the pump is running, the status indicator will dis-

play ‘‘CPP’’.

5. The cooling water temperature will be checked and, if it

is not too low, the cooling tower fan will be started, if not

already running. The status indicator will now display

‘‘CPP’’. At the same time, the solution pump and burner

will be started. The refrigerant pump will be started after

a short time delay. The chiller is now in normal

operation. The control system will continuously monitor

the capacity controller for load requirements, the safety

interlocks for abnormal conditions, and operating limits

for override control when necessary.

Typical Control Sequence — Normal Heating

Start (Fig. 24)

1. When power is supplied to the chiller control panel and

the machine is not in operation, the status indicator will

display ‘‘000’’.

2. For starting, the machine and burner switches should be

positioned as shown in Table 8, and the manual cooling/

heating valves positioned for heating (Table 9).

NOTE: The Heat switch selection must be made before

the Start button is depressed.

3. When the Start button is depressed, the microprocessor

will initiate the timed starting and system checks se-

quence. The hot water pump will be started, if not al-

ready running. After 20 seconds, the pump run interlock(s)

will be checked to verify it is running. If it is, the status

indicator will display ‘‘HPO’’. If not, the sequence will

be halted until the interlocks show the pump is running.

4. The capacity controller then will be queried to see if there

is a need for heating. If not, the sequence will be halted.

If there is, the start sequence will proceed.

5. The solution pump and the burner will be started. The

status indicator will display ‘‘HPO’’. The heater is now

in normal operation. The control system will continu-

ously monitor the capacity controller for load require-

ments, the safety interlocks for abnormal conditions, and

operating limits for override control when necessary.

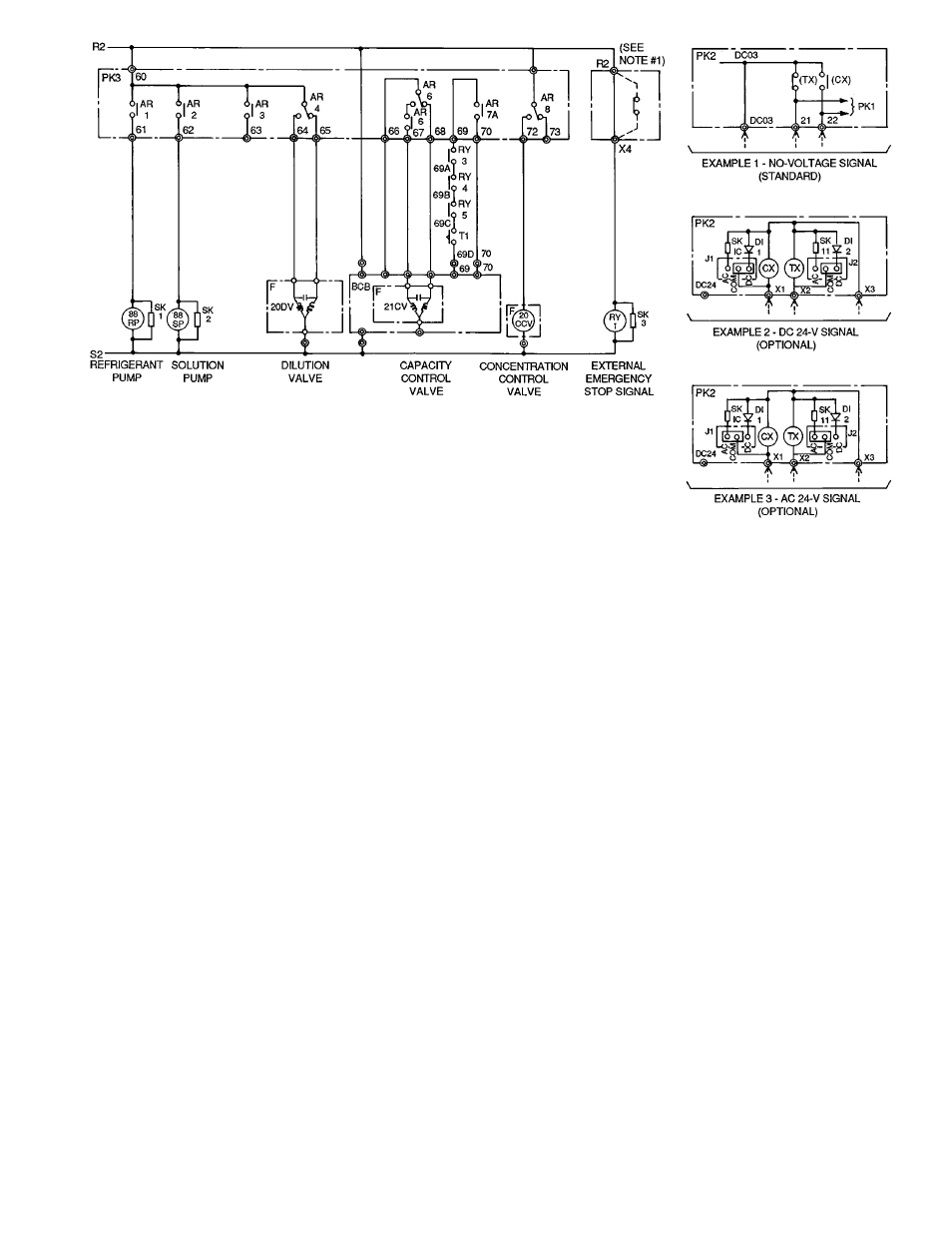

NOTES:

1. When the contacts of external emergency stop signals are con-

nected, remove the jumper wire between terminal R2 and X4 and

connect external contacts to these terminals.

2. BCB — installed in burner control box.

3. F — Positioning motor.

4. PK2 — input terminal module in control panel.

5. PK3 — output terminal module in control panel.

REMOTE OPERATION CIRCUIT

Fig. 23 — PK2 and PK3 Partial Wiring Connections

25