Carrier 16DF013-050 User Manual

Page 40

10. Place the burner on full AUTO. control and provide enough

load on machine for continued operation at high fire for

3 to 5 days. Periodically check the weak solution con-

centration (see Solution or Refrigerant Sampling in Main-

tenance Procedures section, page 48) to be sure the strong

solution is not approaching crystallization. It may be nec-

essary to leave the TS2 dilution valve on MANUAL dur-

ing cooling operation if there is not enough load for

continued burner operation at high fire.

Add Octyl Alcohol —

When the initial start-up is per-

formed during cooling operation, add the amount of initial

octyl alcohol specified in Table 14 before normal operation

is started. When starting during heating operation, do not

add the initial octyl alcohol charge until the machine is switched

over to cooling.

Add the alcohol through the high-temperature generator

drain valve according to the instructions under Adding Oc-

tyl Alcohol in the Maintenance Procedures section page 49,

do not allow air to be drawn into the machine.

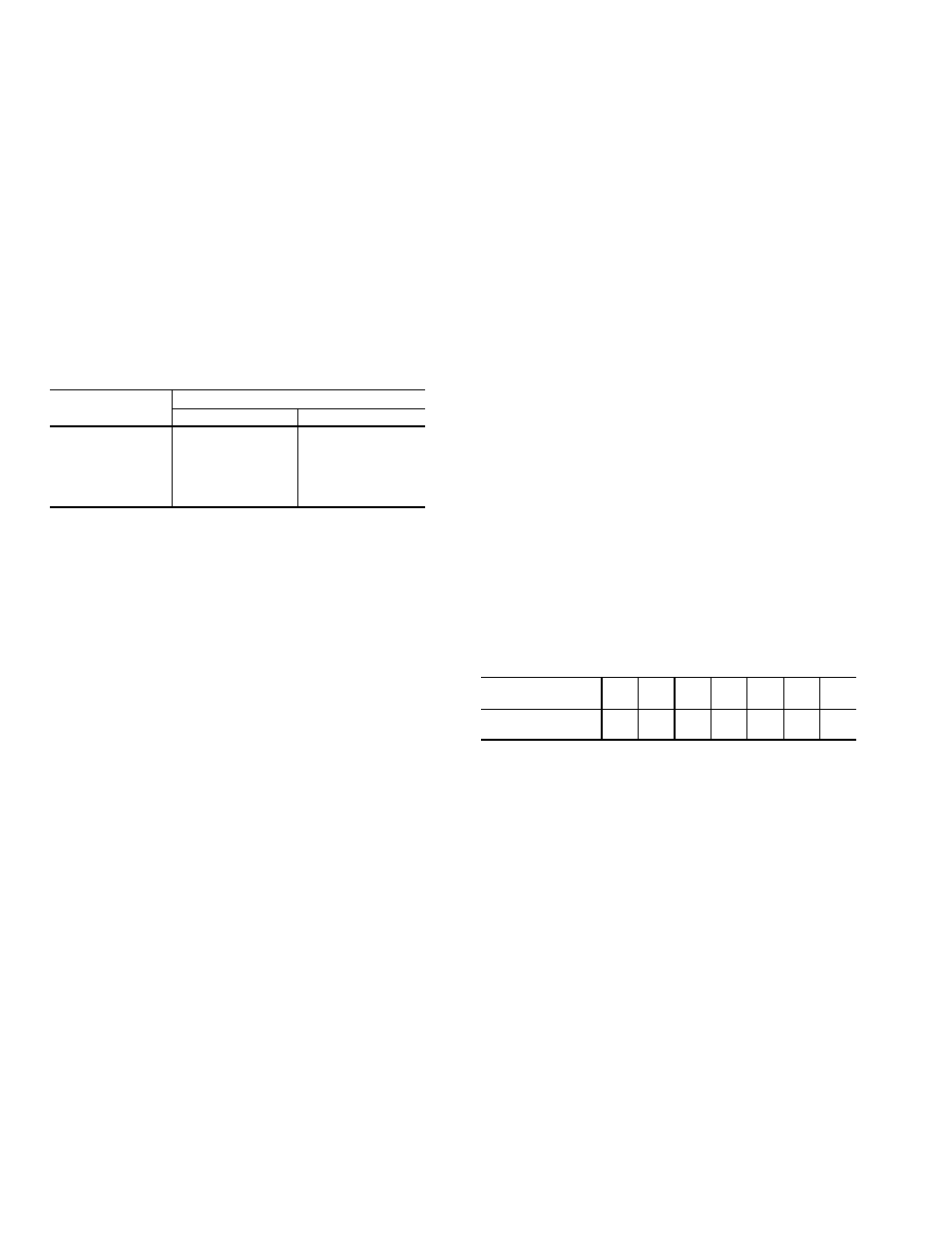

Table 14 —Octyl Alcohol Initial Charge

16DF

OCTYL ALCOHOL

Gal.

L

013,015

2

7.6

018,020

2

7.6

023,025

2

7.6

028,032

3

11.4

036,040

3

11.4

045,050

4

15.2

Initial Start Operation —

When the initial combus-

tion run-in period has been completed, normal operation may

begin. Start machine following the procedures described in

Operating Instructions section for Start-Up After Extended

Shutdown, page 43. Evacuate the machine to remove non-

condensables if the absorber loss is above 5° F (2.8° C). If

the absorber loss is below 5° F (2.8° C), the machine may

be placed in AUTO. control for normal operation.

Capacity Control Adjustments —

The control set

points for the leaving chilled water and hot water tempera-

tures are factory set but may be adjusted, if necessary, ac-

cording to the Automatic Capacity Control explanations in

the Machine Controls section, page 31.

Refrigerant Charge Final Adjustment —

The re-

frigerant charge final adjustment must be made to ensure that

normal solution concentrations can be achieved for full ca-

pacity and that refrigerant overflow will occur with exces-

sive solution concentrations to prevent crystallization. The

adjustment should be made only when:

1. machine is operating on cooling with stable temperatures

at 40 to 100% of full load;

2. absorber loss is 3° F (1.7° C) or less; and,

3. refrigerant specific gravity is 1.02 or less.

Proceed as follows:

1. Remove a solution sample from the solution pump

service valve and measure the specific gravity and

temperature.

2. Locate the intersection point of the specific gravity and

temperature values on equilibrium diagram (Fig. 30A or

30B). Read down from this point to the solution concen-

tration scale to determine the percent lithium bromide by

weight in the weak solution.

3. Determine the approximate percent of full load on the ma-

chine by comparison of chilled water temperature spread

and flow in relation to design. Enter Table 15 at this per-

cent load and find the corresponding weak solution con-

centration required for refrigerant charge adjustment un-

der nominal conditions.

4. Adjust machine operating conditions until machine op-

erates with stable temperatures at either of the weak so-

lution concentrations (±0.1%) listed in Table 15 under the

selected percent load.

To increase the concentration:

a. Increase the load.

b. Lower

chilled

water

temperature

(set

point

adjustment)

c. Raise condensing water temperature (or reduce con-

densing water flow).

After adjusting conditions, repeat Steps 1 and 2 to verify

solution concentration.

5. Check the relative temperature of the evaporator refrig-

erant overflow pipe.

a. If it is cold (about the same temperature as the refrig-

erant pump discharge), the machine may have too much

refrigerant. Remove about 3.8 L (1 gal.) of water through

the refrigerant pump discharge valve. Continue to re-

move water in 3.8 L (1 gal.) increments until the over-

flow stops. Wait about 10 minutes between reductions

to allow for temperature changes to be noted. Refrig-

erant overflow will change machine operating condi-

tions, so repeat Steps 1 through 4 periodically.

b. If it is warm (close to ambient temperatures, the ma-

chine may have too little refrigerant. Add about

3.8 L (1 gal.) of water through the refrigerant pump

service valve. Do not allow air to be drawn into the

machine. Continue to add water in 3.8 L (1 gal.) in-

crements until overflow just starts. Wait about 10 min-

utes between additions to allow for temperature changes

to be noted.

Table 15 — Weak Solution Concentration For

Refrigerant Charge Adjustment

PERCENT LOAD

ON MACHINE

100

90

80

70

60

50

40

WEAK SOLUTION

CONCENTRATION

60.0

60.4

60.8

61.2

61.6

61.9

61.2

Check Machine Shutdown —

Press the Stop button

to verify normal shutdown sequencing. The burner should

drive to low fire and then stop. The machine will go through

a dilution shutdown period and the pumps will stop accord-

ing to the Typical Control Sequence for Normal Cooling Stop

or Normal Heating Stop described in the Machine Controls

section, page 28.

OPERATING INSTRUCTIONS

Operator Duties

1. Become familiar with absorption machine and related equip-

ment before operating. See Introduction and Machine De-

scription sections, page 3.

2. Start and stop machine as required.

3. Inspect equipment; make routine adjustments; maintain

machine vacuum and proper refrigerant level; exhaust purge

as required; check and maintain combustion system.

4. Keep log of operating conditions and recognize abnor-

mal readings.

5. Protect system against damage during shutdown.

40