Carrier 16DF013-050 User Manual

Page 33

Inspect Field Piping —

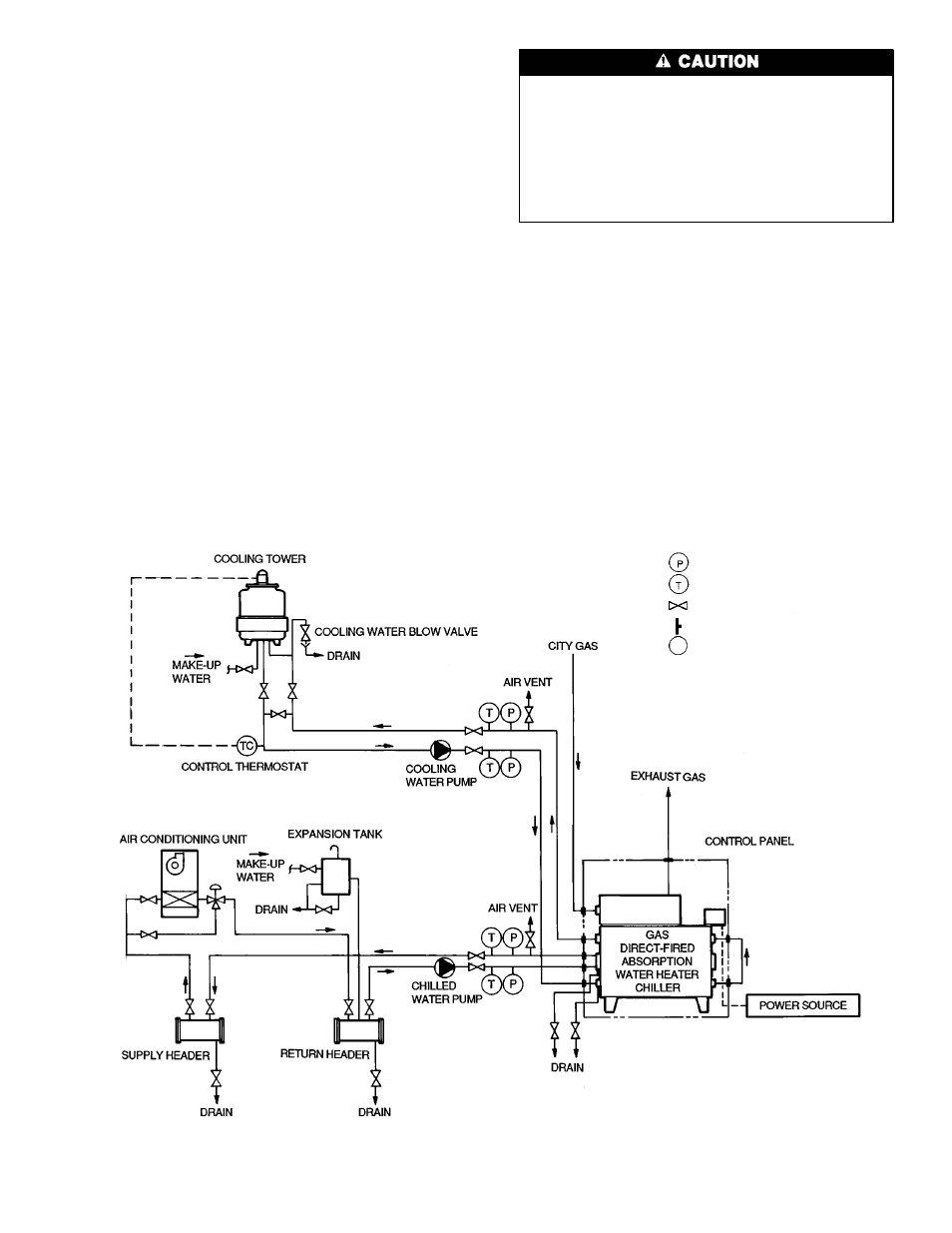

Refer to the field piping dia-

grams and inspect the chilled/hot water and cooling water

piping. (See Fig. 28 for typical piping arrangement.)

1. Verify location and flow direction of the water lines as

are specified on the drawings.

2. Check that all water lines are vented and properly sup-

ported to prevent stress on water box covers or nozzles.

3. Make sure all water box drains are installed.

4. Ensure that water flow through the evaporator and con-

denser meet job requirements. Measure the pressure drops

across both cooler and condenser water tube bundles when

the system has been charged with water and the pumps

can be operated.

5. Make sure chilled/hot water temperature sensors are in-

stalled in the leaving and entering chilled/hot water pip-

ing. Also check that appropriate thermometers or temperature

wells and pressure gage taps have been installed in both

entering and leaving sides of the evaporator, absorber, and

condenser water piping.

Inspect Field Wiring —

Refer to the field and ma-

chine wiring diagrams and inspect the wiring for both power

supply and connections to other system equipment (cooling

tower, water supply pumps, auto. start if used, etc.).

Do not connect or disconnect any wiring, and do not

touch any bare wires or wiring terminals unless power

supply disconnects have been locked open and tagged.

Do not apply power to hermetic pumps or attempt to

start the machine until it has been charged with lithium

bromide solution and refrigerant at initial start-up. The

pumps will be severely damaged if rotated without the

full liquid charge. Open disconnects in control panel if

power is to be applied.

1. Examine wiring for conformance to job wiring diagrams

and applicable electrical codes.

2. Check pump and motor nameplates and control panel for

agreement with supply voltage and frequency (hertz).

3. Verify correct overload and fuse sizes for all motors.

4. Check that electrical equipment and controls are properly

grounded in accordance with applicable electrical codes.

5. Make sure customer/contractor has verified proper op-

eration of water pumps, cooling tower fan, and associ-

ated auxiliary equipment. This includes ensuring that motors

are properly lubricated and have correct electrical power

supply and rotation.

NOTE: See manufacturer’s burner manual for fuel line components.

Fig. 28 — Typical Piping and Wiring

Pressure Gage

Thermometer

Valve

Piping Connection

Pump

ᮣ

33