Shutdown below freezing conditions, Actions after abnormal shutdown (fig. 26 ), Actions after power interruption – Carrier 16DF013-050 User Manual

Page 45

Shutdown Below Freezing Conditions —

Begin

by shutting the machine down with Normal Shutdown

Procedure.

Then transfer most of the refrigerant into the solution:

1. Turn the burner control switch to OFF and depress the

machine Start button. Then depress the machine Stop but-

ton to start the dilution cycle.

2. Open the changeover valve ‘‘B’’ under the refrigerant tank

to drain refrigerant into the absorber.

3. After about 10 minutes, close the changeover valve ‘‘B’’.

4. The machine will stop after a dilution period of about

15 minutes.

The refrigerant circuit requires special treatment to prevent

freezing:

1. Fill a hose with water (to avoid letting air into the ma-

chine) and connect the hose between the solution pump

and refrigerant pump service valves.

2. Push machine Start button (while burner control switch

is still in the OFF position) to start the pumps.

3. Open both pump service valves for about 15 minutes. The

solution pump discharge pressure is higher so solution

will flow into the refrigerant circuit to provide antifreeze

protection.

4. Depress machine Stop button, return the burner control

switch to ON, open the control panel main circuit breaker

(MCB), and remove the transfer hose.

Completely drain all water tube bundles and flush all tubes

with an antifreeze chemical such as glycol.

Actions After Abnormal Shutdown (Fig. 26 ) —

Abnormal stop occurs automatically when any of the safety

devices sense a condition exceeding their normal safe op-

erating limit. When this happens, the fuel valve is closed,

the alarm buzzer sounds, and the machine shuts down. The

cause of the safety shutdown will be displayed in code by

the status indicator on the front of the control panel. These

codes are listed in Table 16. In case of a burner or combus-

tion failure, an alarm light on the burner control panel also

illuminates.

Some safety conditions will close the fuel valve imme-

diately, and others will first modulate the burner to the mini-

mum firing position for a normal low fire shutdown. Also,

most safety conditions will allow the normal shutdown di-

lution period but some will stop the machine immediately

without dilution. The latter conditions should be corrected

as quickly as possible to allow a restart or manual dilution

before solution crystallization can occur. See Abnormal Shut-

down in the Machine Controls section, page 29 for limit set-

tings and shutdown action for each safety type.

Take the following actions after an abnormal shutdown:

1. Identify the problem from the control panel status indi-

cator, and also from the burner control panel if it is a burner

problem.

2. Depress the machine Stop button to silence the buzzer

and to reset the control circuit for a restart after noting

the failure code.

3. Correct the cause of the problem and restart the machine

to be sure it operates normally. See Troubleshooting Guide,

pages 54 - 56 for remedies. If shutdown occurred with-

out adequate dilution, this should be done as soon as

possible.

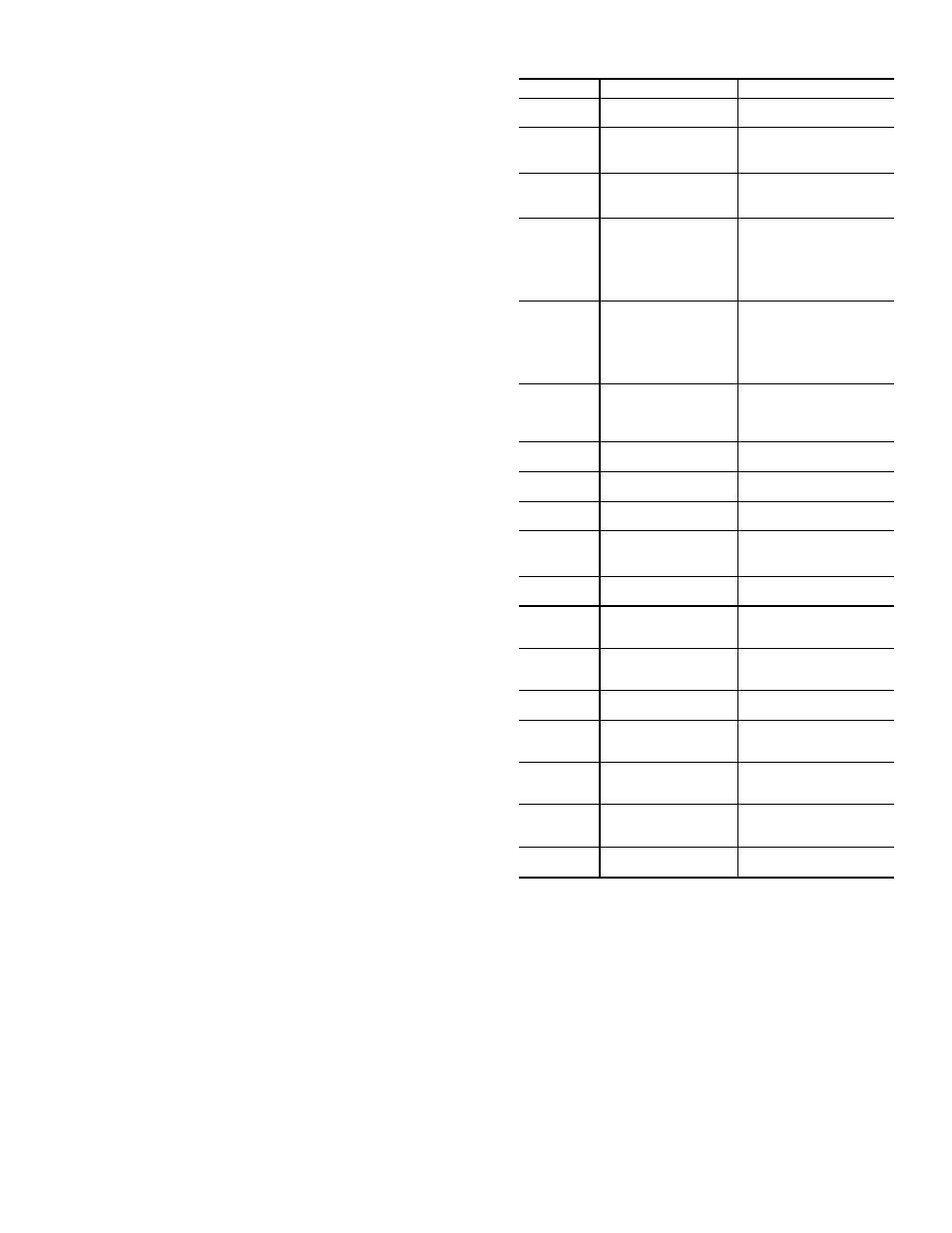

Table 16 — Safety Devices Status

Indication Summary

INDICATION

CAUSE

SAFETY DEVICE

E01

Chilled water

low temperature

Chilled water

low temperature cutout

E02

Chilled/hot water

low flow

Flow switch

Chilled/hot water pump

interlock

E03

Cooling water

low flow

Optional Flow Switch

Cooling water pump

interlock

E04

Hermetic pumps

overload

Solution pump thermal

relay

Solution pump coil

thermostat

Refrigerant pump thermal

relay

E05

Generator high

temperature or

high pressure

High temperature

generator

pressure switch

High temperature

generator solution

temperature sensor

E06

Exhaust gas

high temperature

Exhaust gas high

temperature thermostat

Fire tube high

temperature thermostat

E07

Absorber high

temperature

Absorber solution

temperature sensor

E08

Burner — no ignition

Burner flame detector

and combustion controller

E09

Burner — misfire

Burner flame detector and

combustion controller

E10

External limit device

External emergency

stop switch

Main power failure

E12

Chilled/hot water

flow check

Flow switch,

pump interlock

E13

High-temperature

generator,

solution high level

High-temperature

generator solution

level sensor

E17

Leaving chilled/hot

water temperature

Chilled/hot water

outlet temperature

sensor

E18

Absorber solution

temperature

Absorber solution

temperature sensor

E19

High-evaporator

generator,

refrigerant temperature

High-temperature

generator, refrigerant

temperature sensor

E20

Entering chilled/

hot water

temperature

Chilled/hot water inlet

temperature sensor

E24

High-temperature

generator,

solution temperature

High-temperature

generator, solution

temperature sensor

E90

Insufficient dilution

Control circuit

power failure

Actions After Power Interruption —

If the control

power is interrupted during operation, the chiller stops im-

mediately without the normal shutdown sequence and

dilution.

Solution crystallization can occur if the concentration is

high (chiller was operating with a relatively large load). If

so, depress the Start button to restart the machine as soon as

possible after the power is restored. The machine will not

restart automatically when power is recovered. If the chiller

cannot be operated because of crystallization, follow the So-

lution Decrystallization instructions in the Maintenance Pro-

cedures section, page 53.

45