Troubleshooting guide (cont) – Carrier 16DF013-050 User Manual

Page 56

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 211

Catalog No. 531-603

Printed in U.S.A.

Form 16DF-1SS

Pg 56

801

5-92

Replaces: New

Book 1

Tab

5b

Copyright 1992 Carrier Corporation

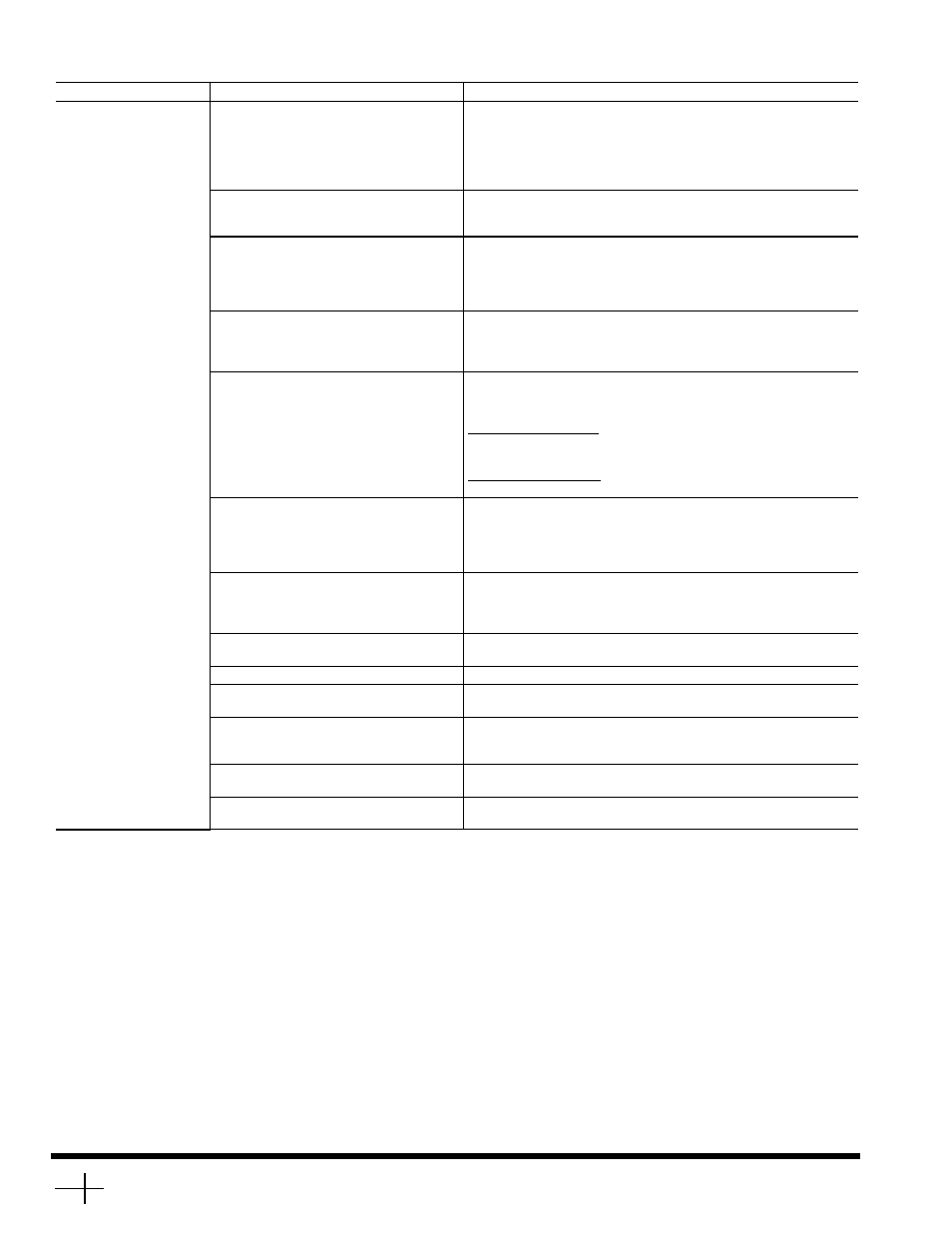

TROUBLESHOOTING GUIDE (cont)

PROBLEM/SYMPTOM

PROBABLE CAUSE

REMEDY

Abnormal stop

(fault code

displayed with

alarm buzzer)

Code “E01” (cooling only) —

low chilled water temperature

at or below 39 F (4 C)

Verify that chilled water low temperature cutout opens at

factory setting of 39 F (4 C) (see Check Low Chilled Water

Temperature Cutout section, page 35). Also verify that

the capacity control low-temperature limit turns the burner off

at no less than 41 F (5 C ) (see Machine Controls,

Automatic Capacity Control section, page 31).

Code “E02” — Low chilled/hot water

flow, or chilled/hot water

pump interlock(s) are open

Verify chilled/hot water pump is running, discharge pressure

is normal, valves are correct, and piping strainers are clear.

Code “E03” (cooling only) —

Condensing water pump

interlock(s) are open,

or low flow when flow switch

is used

Verify condensing water pump is running, discharge pres-

sure is normal, valves are correct, and piping strainers are

clear.

Code “E04” — Solution or

refrigerant pump motor overloads

or high motor temperature

switches

Press overload relay reset button if overload has tripped.

Check overload setting, motor run amps, pump discharge

pressure, and motor temperature. If solution pump has tripped,

check for solidification.

Code “E05” — High-temperature

generator, high solution temperature,

or high pressure

Verify high-stage generator limit settings of 338 F (170 C) for

strong solution temperature and –0.8 in. Hg (–20 mm Hg) for

maximum pressure, and check switch operation.

For cooling operation, check cooling water for high temper-

ature or low flow. Place the dilution switch in MANUAL for

about 3 minutes to dilute and cool the solution.

For heating operation, verify the machine switchover valves

are fully open.

Code “E06” — High flue gas,

fire tube, or refractory temperature

Verify temperature limit settings for exhaust stack and fire

tube are at 572 F (300 C) and the refractory is at 302 F

(150 C), then check switch operation. Check for dirty

generator tubes or damage to return end cover refractory.

Adjust burner controls or repair refractory if necessary.

Code “E07” (cooling only) —

High absorber weak solution

temperature

Verify absorber weak solution temperature above 113 F

(45 C). Check for low cooling water flow or high tem-

perature. Also check for poor absorber heat transfer

(dirty tubes).

Code “E08” — Burner ignition failure

See Cause and Remedies under Burner Misfire on Ignition

Attempt.

Code “E09” — Burner operation failure See burner manual for correction instructions.

Code “E10” (optional) — External

limit device

Determine what condition is being sensed and the cause of

the fault.

Code “E12” — Chilled/hot water pump

interlock open but flow switch is closed,

or vice versa

Check chilled/hot water pump operating status and interlock,

flow switch operation, valves, and strainers.

Codes “E13 through E34” —

Sensor error, out of range

Have sensors checked and calibrated.

Code “E90” — Insufficient

shutdown dilution

Repeat dilution cycle by depressing Start then Stop buttons.

Determine reason for inadequate dilution.