Update underside weldments, Configure implement, Tack rear bottom gussets – Great Plains 2007HD Update Installation User Manual

Page 9: Lh rear bottom gussets, Fb d u

05/25/2011

166-370M

Great Plains Manufacturing, Inc.

5

Update Underside Weldments

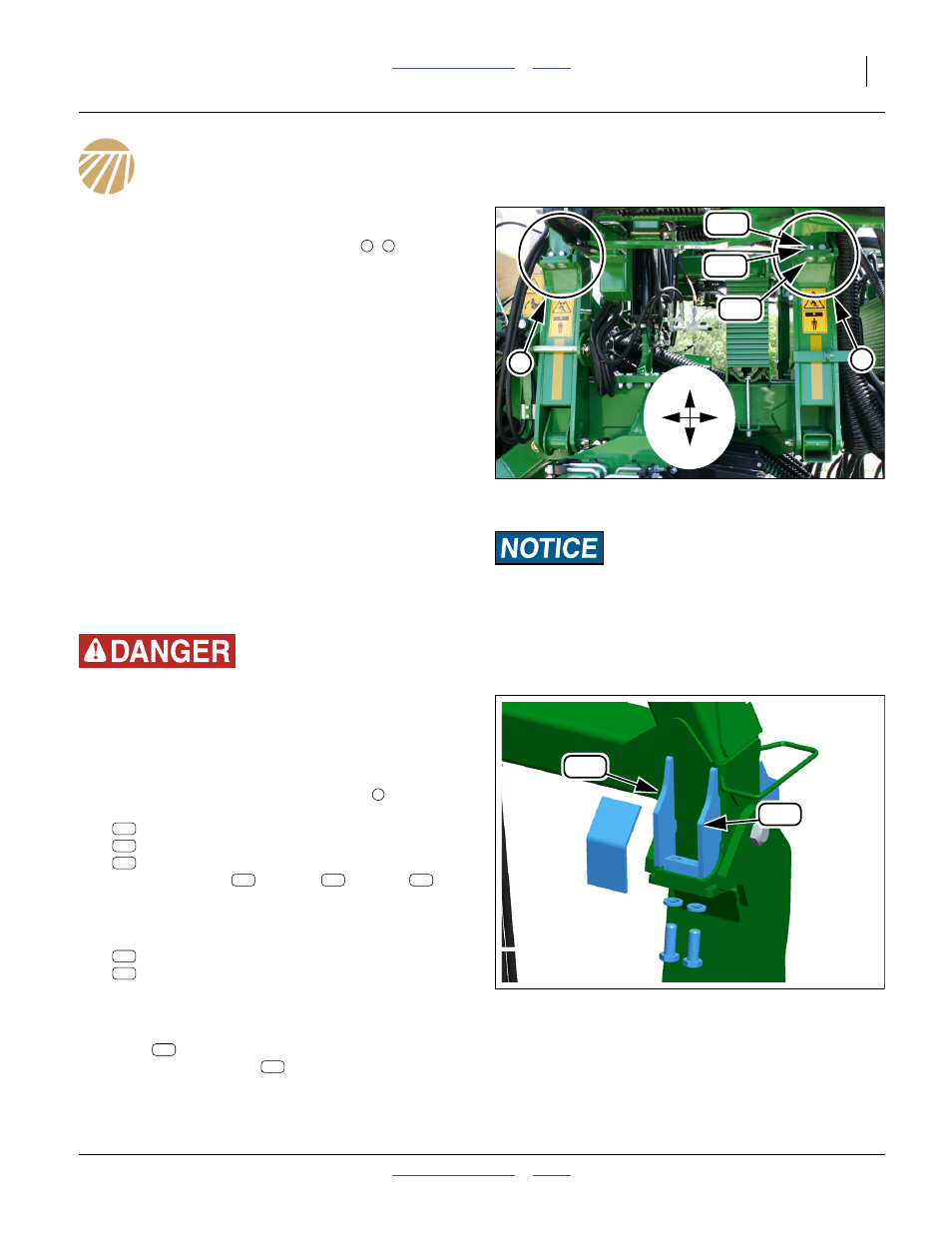

Refer to Figure 2

Gussets, nut blocks and a box plate are added to the

underside of the wing pivot extensions (4

,

locations,

two on each wing). This work is considerably easier with

the implement folded, and needs to be done prior to

cart-implement separation.

Configure Implement

3.

Raise, fold and configure as if for transport (lift locks

and wing fold locks installed). Set all hydraulic

remotes to Float to relieve pressure in lines.

4.

Disconnect all harnesses and cables at cart hitch.

5.

Take steps to protect hoses and cables near weld

regions. Cover with welding blankets, or temporarily

remove, as needed.

Tack Rear Bottom Gussets

LH Rear Bottom Gussets

Start with the left (LH) side. The left and right side new

parts are not identical, although they are similar and

install in mirror-image locations.

Crushing Hazard:

Remove only the underside bolts. Do not remove the

cross-bolts or the top side bolts. Removing all the fasteners at

a joint could allow a dangerous joint separation resulting in

serious injury or death, and extensive machine damage.

Refer to Figure 2

6.

At the Back wing pivot extension joint

, remove

two sets:

804-023C WASHER LOCK SPRING 3/4 PLT

802-910C RHSNB 3/4-10 X 2 GR5 PLT

Save the washer

. The nut

not re-used.

Refer to Figure 3

7.

Select one each new:

160-804D FRAME EXT BOT GUSSET LH REWORK

160-805D FRAME EXT BOT GUSSET

REWORK

Hold these in their intended positions. Mark paint for

removal.

8.

Remove paint. Tack weld gusset plates in position.

Plate

is to implement front, against the existing

smaller gusset. Plate

is to implement rear,

against the existing smaller gusset. Place both as

close to the joint and up against the wing as allowed

by pre-existing weld fillets.

Equipment Damage Risk:

Disconnect all electrical connections between cart and tractor

prior to welding. Welding can induce high voltages and/or

high current flows that could damage sensors, WSMB and

WSMTs on the cart or implement.

Figure 2

Underside Work Locations

Q0113

F

B

D

U

F

B

B

F

Figure 3

LH Rear Underside Gussets

Q0120

908

909

B

908

909

908

909