Install meter seal flange, Replace meter shaft mount plates, Replace right end plates – Great Plains 2007HD Update Installation User Manual

Page 22

18

NTA607HD or NTA2007HD

Great Plains Manufacturing, Inc.

166-370M

05/25/2011

Install Meter Seal Flange

Refer to Figure 28 (new holes not shown)

85. For each meter, select two new:

266-306D METER SEAL FLANGE

86. Clamp the flange seals

on the meter top panel,

around the opening. Make sure the ends

of the

seals touch each other.

87. Tack weld the seal to the top panel at the corners,

halfway point on front and back, and at end joints

.

88. Clean off any splatter or burned paint.

89. Allow the welds to cool.

90. Touch up bare/discolored areas with green enamel.

91. Allow paint to dry. Apply a bead of silicone sealant

to the inside corner of the top panel / seal flange

joint. Smooth the bead into a fillet shape.

Replace Meter Shaft Mount Plates

Replace Right End Plates

Refer to Figure 29

92. For each meter, select one new:

168-472D METER SHAFT MOUNT PLATE

Apply a bead of silicone sealant to one face of the

plate, in a circle around each outer bolt hole, and in

a circle on the outer bolt hole center-lines.

93. Select six sets new:

802-001C HHCS 1/4-20X3/4 SS

804-033C WASHER LOCK 1/4 SS

Apply silicone sealant under bolt heads and under

washer faces. Secure the plate

to the right end

of the meter. Smooth excess sealant to fillet shape.

94. Select the saved flute shaft

. Temporarily insert

the flute shaft from meter left.

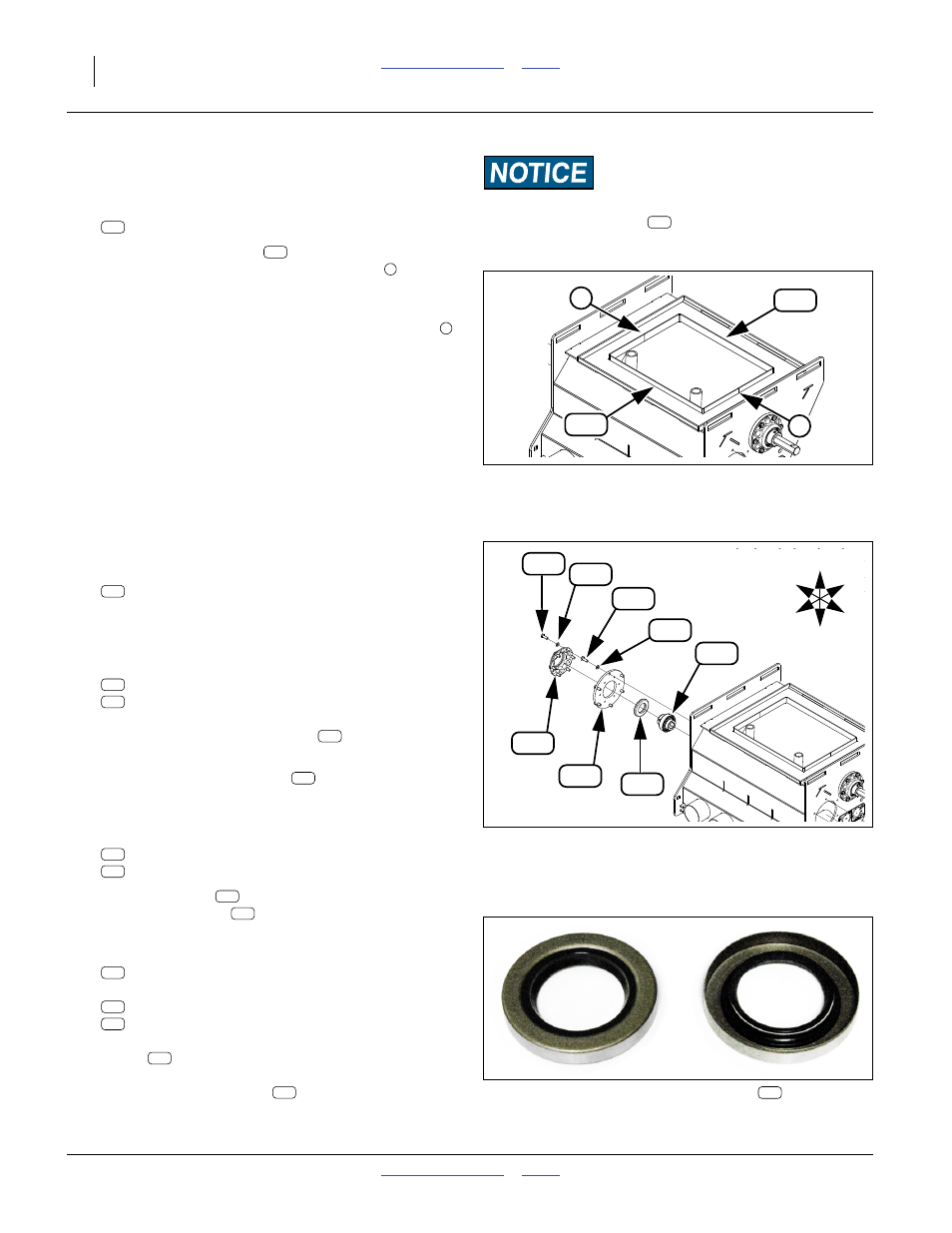

Refer to Figure 30

95. Select one set saved:

188-009V BRG .755 HEX BORE W/S-S

816-199C SEAL 1.33IDX2.23ODX.31T

Add the bearing

, with set screw collar to the

right. Add the seal

with the solid face to the out-

side and the open face toward the meter.

96. Select one saved:

890-466C HSG RIBB FLG 6BOLT PLT

and six sets new:

802-001C HHCS 1/4-20X3/4 SS

804-033C WASHER LOCK 1/4 SS

Apply silicone sealant to the outer rim of the

flange

. Place the flange over the bearing. Apply

silicone sealant under bolt heads and under washer

faces. Secure the flange

to the right end of the

meter. Smooth any excess sealant into a fillet

shape.

Figure 28

Meter Seal Flange

Q0103

924

924

3

3

Equipment Damage Risk:

Check that the flute shaft (

in Figure 25 on page 16) is

removed prior to welding. Slag and splatter can rapidly and

severely damage meter flutes and fillers.

125

924

924

3

3

Figure 29

Right Shaft Mount Plate

Q0103

918

942

231

959

218

134

942

959

U

D

F

B

L

R

918

942

959

918

125

134

218

Figure 30: 816-199C Seal

Orientation: Outside / Inside

32122

218

134

218

231

942

959

231

231