Update coulters, Prepare implement, Replace coulter bars – Great Plains 2007HD Update Installation User Manual

Page 69: Remove existing bar

05/25/2011

166-370M

Great Plains Manufacturing, Inc.

65

Update Coulters

Prepare Implement

366. Hitch the air drill to a tractor, or connect the lift and

fold circuits to a hydraulic source. Raise the imple-

ment. Check for hydraulic leaks.

367. See Operator manual for details on center locking

and lock channels.

368. Install lock channels.

369. Engage the center lift lock.

370. Lower implement onto locks.

371. Set hydraulic circuits to Float. Shut down tractor or

hydraulic source.

Replace Coulter Bars

Repeat the following steps for each row. To minimize the

risk of re-assembly errors, perform a complete update to

a single row before moving to another row. If multiple

workers are available, multiple drill sections may be

worked on simultaneously.

Remove Existing Bar

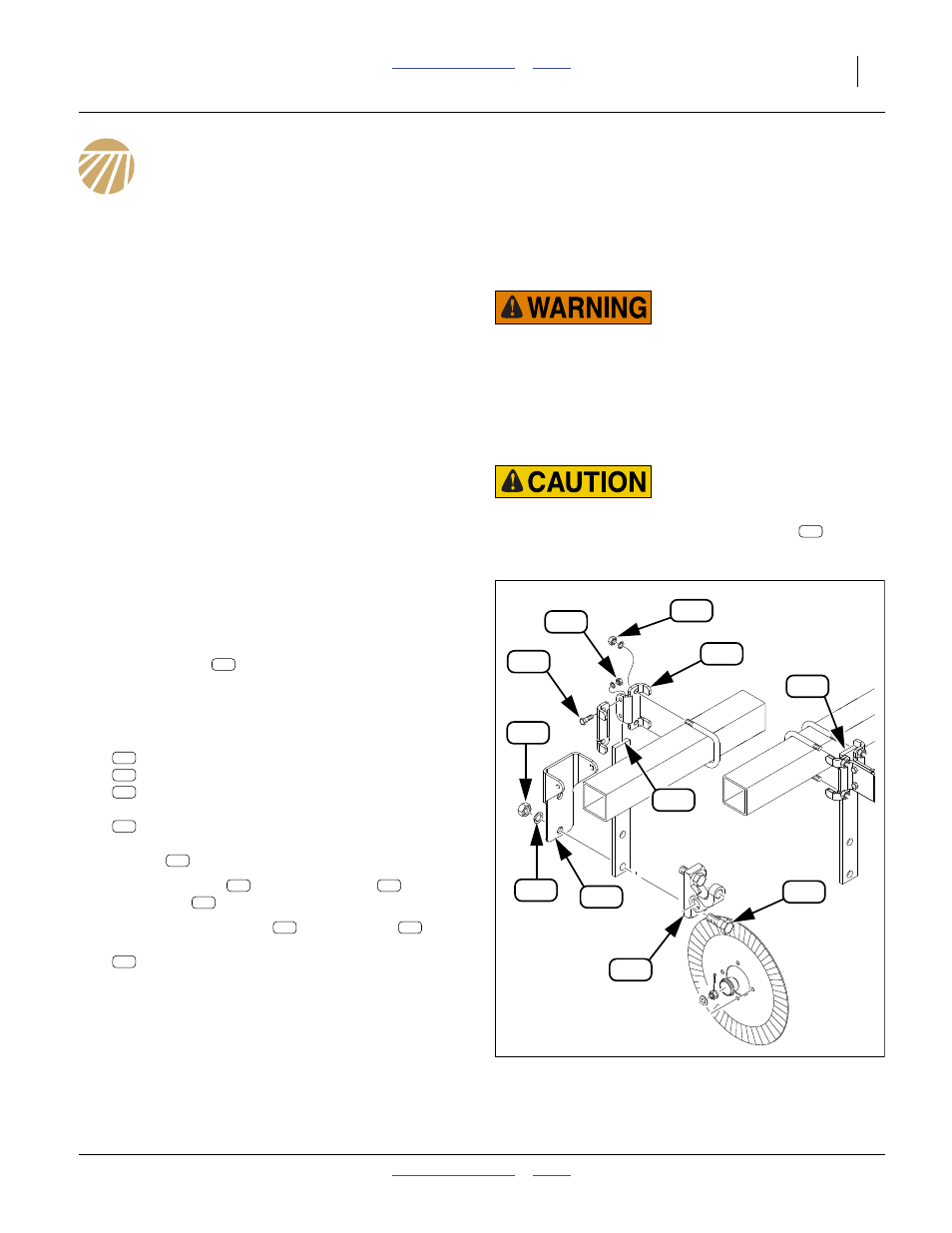

Refer to Figure 104

372. Make note of current coulter height. Check the loca-

tion of the bar

tops with respect to the tool bar,

or the distance from the bottom of the tool bar to the

bottom edge of the coulter disk. Some rows may run

at different heights (for tire compensation).

373. Remove and save two sets:

804-037C WASHER LOCK SPRING 7/8 PLT

and the mount:

then dismount the coulter assembly at the

casting

.

374. Loosen the nuts

at the cross-bolts

between

the clamps

375. Loosen the U-bolt nuts

Remove the existing coulter bar:

204-280D 18" COULTER SPRING BAR-PAINTED

This bar is not re-used.

Figure 104

Coulter Dismounting

29353

177

167

High Pressure Fluid Hazard:

Wear gloves and goggles when checking hydraulic connec-

tions. Use cardboard to check for leaks. Check for leaks care-

fully. If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Sharp Object Hazard:

Wear gloves when handling the coulter assembly

. The disc

may be sharp and contaminated with soil. The assembly is

heavy.

177

167