Re-hitch implement, Install front pull link, Re-connect lift link – Great Plains 2007HD Update Installation User Manual

Page 61

05/25/2011

166-370M

Great Plains Manufacturing, Inc.

57

Re-Hitch Implement

Install Front Pull Link

Pinch / Crush Hazards:

Use an adequate hoist or lifter. Use three or more lines. Place

lines where they cannot slip. The weldment

weighs over

270 kg (600 pounds).

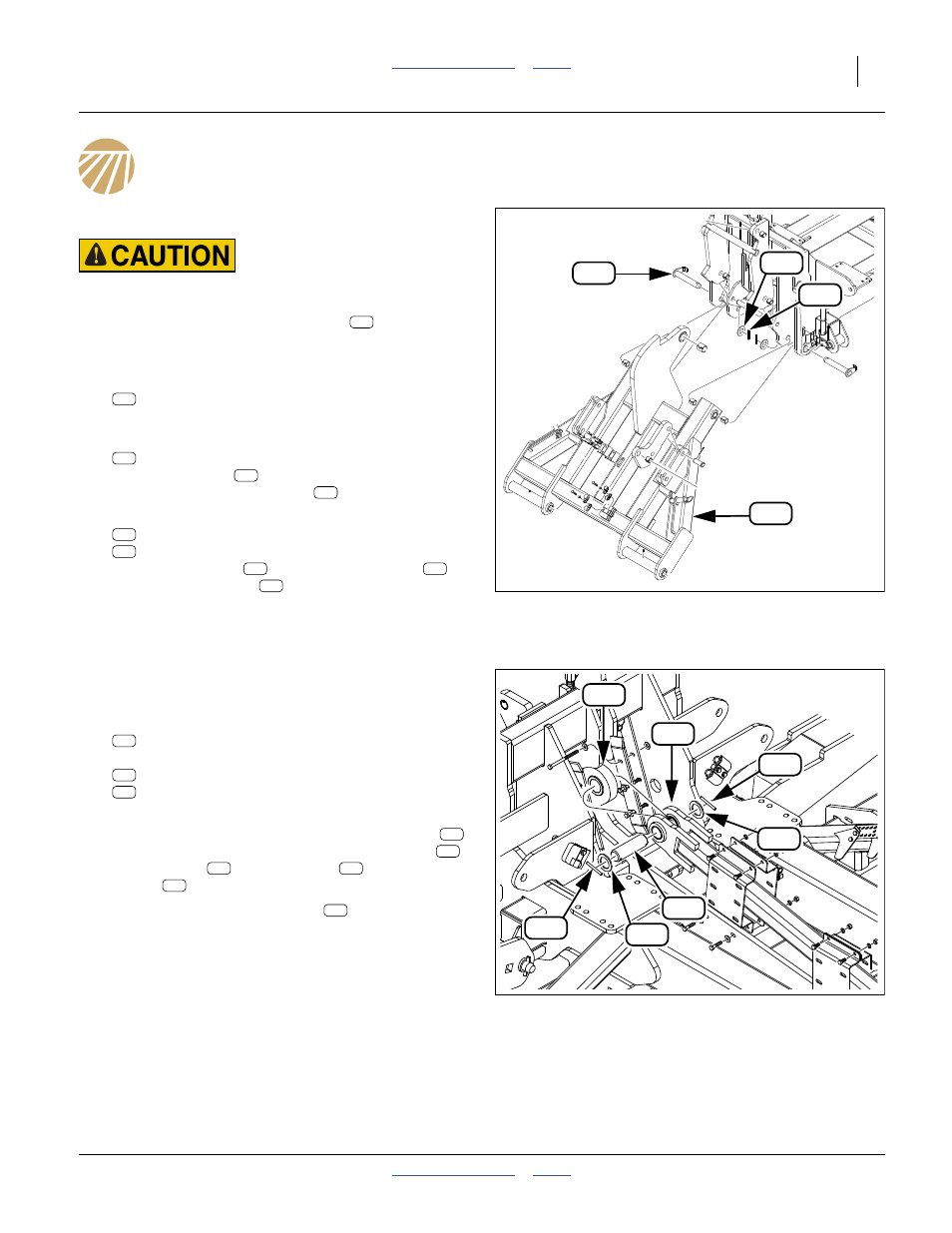

Refer to Figure 91

331. Select one new:

160-315H NTA607HD FRONT PULL LINK WLDMT

Attach a hoist.

332. Select two saved:

160-201H WING PIVOT PIN WELDMENT

Hoist the pull link

into alignment with the imple-

ment main frame. Insert pins

.

333. Select two sets saved:

804-039C WASHER FLAT 1 1/4 SAE PLT

805-255C PIN ROLL 3/8 X 2 1/2 PLT

Place the washers

on the weldment pins

.

Secure with poll pins

. Leave the hoist attached

to the pull link.

Re-Connect Lift Link

Refer to Figure 92

334. Select one saved:

160-781D PIN 1 1/2 X 4 USABLE 1045

with its two sets of:

804-117C WASHER FLAT 1/4 HARD ASTMF436

805-117C PIN ROLL 1/4 X 2 1/2 PLT

Remove one washer and roll pin.

335. Use the hoist to bring the top lug of the pull link

into alignment with the front clevis of the lift link

.

Insert the pin

. Add a washer

. Secure with

roll pin

.

336. Check the length of the lift link

. Adjust the rear

clevis turnbuckle as needed to obtain a length,

clevis center-line to clevis center-line of:

202.0 cm (79

17

⁄

32

in)

Note: Although the hoist could be disconnected from the

pull link at this time, it may be useful for implement-

cart hitching.

Figure 91

Install New Front Pull Link

31238

902

193

104

200

902

902

104

902

104

193

200

193

104

200

Figure 92

Connect Lift-Assist Link

31423

112

902

196

194

118

194

196

118

194

196

902

112

118

194

196

112