tekmar 362 Mixing Control Installation User Manual

Page 7

7 of 36

Copyright © D 362 -

12/08

HRF 1

HRF 2

COIL

CONV

RAD

BASE

ROOM OCC & UNOCC (ROOM)

(

CHARACTERIZED

HEATING

CURVE

)

The ROOM is the desired room temperature for the mixing zones and it provides a parallel shift of the

Characterized Heating Curve.

The room temperature desired by the occupants is often different from the design indoor temperature (MIX INDR). If the room

temperature is not correct, adjusting the ROOM

setting increases or decreases the amount of heat available to the building. If the

Setback / None DIP switch is set to Setback, a ROOM setting must be made for both the Occupied and UnOccupied modes.

MIXING TARGET TEMPERATURE (MIX TRG)

(

RESET

RATIO

&

CHARACTERIZED

HEATING

CURVE

)

The MIX TRG temperature is determined from either the

Characterized Heating Curve or the Reset Ratio settings and the outdoor air

temperature. The control displays the temperature that it is currently trying to maintain as the mixing supply temperature. If the control

does not presently have a requirement for heat, it displays “- - -” in the LCD.

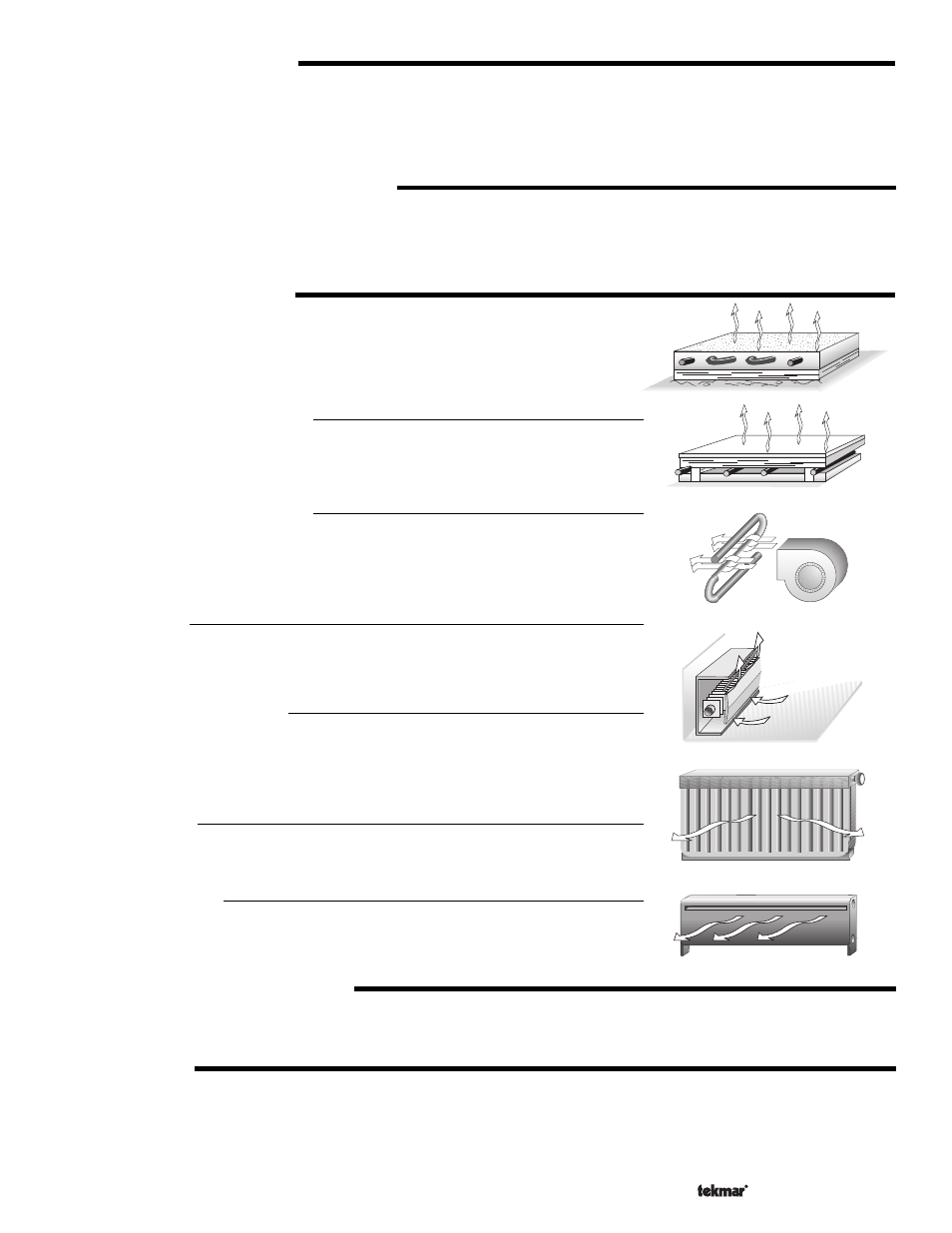

TERMINAL UNITS (TERMINAL)

When using a

Characterized Heating Curve, the control requires the selection of a terminal

unit. The terminal unit determines the shape of the

Characterized Heating Curve according

to how the terminal unit delivers heat into the building space. The 362 provides for selection

between six different terminal unit types: two types of radiant floor heat, fancoil, fin-tube

convector, radiator and baseboard.

Hydronic Radiant Floor (HRF 1)

HRF1 is a heavy, or high mass, hydronic radiant floor system. This type of a hydronic radiant

floor is embedded in either a thick concrete or gypsum pour. This heating system has a large

thermal mass and is slow acting.

Hydronic Radiant Floor (HRF 2)

HRF2 is a light, or low mass, hydronic radiant floor system. Most commonly, this type of

radiant heating system is either attached to the bottom of a wood sub floor, suspended in

the joist space, or sandwiched between the subfloor and the surface. This type of radiant

system has a relatively low thermal mass and responds faster than a high mass system.

Fancoil (COIL)

A fancoil terminal unit or air handling unit (AHU) consists of an hydronic heating coil and

either a fan or blower. Air is forced across the coil at a constant velocity by the fan or blower

and is then delivered into the building space.

Fin–tube Convector (CONV)

A convector terminal unit is made up of a heating element with fins on it. This type of terminal

unit relies on the natural convection of air across the heating element to deliver heated air

into the space. The amount of natural convection to the space is dependant on the supply

water temperature to the heating element and the room air temperature.

Radiator (RAD)

A radiator terminal unit has a large heated surface that is exposed to the room. A radiator

provides heat to the room through radiant heat transfer and natural convection.

Baseboard (BASE)

A baseboard terminal unit is similar to a radiator, but has a low profile and is installed at the

base of the wall. The proportion of heat transferred by radiation from a baseboard is greater

than that from a fin-tube convector.

MIXING PUMP OPERATION (Mix Pmp)

The Mixing Pump contact (

Mix Pmp, terminal 5) closes whenever there is a Mixing Demand and the 362 is not in WWSD. During WWSD,

the mixing pump is operated based on the EXERCISE setting in the

Adjust Menu.

PURGE (PURGE)

After the

Mixing Demand has been satisfied, the 362 can continue to operate the Mixing Pump for a period of time. The length of time

that the Mixing Pump continues to run is an adjustable time setting. This setting allows any excess heat to be purged out to the heating

system. The Mixing Pump continues to run until the Purging time has elapsed or the mixing supply temperature drops below the MIX

MIN setting. This setting should not be used if the mixing system is zoned using either zone pumps or fast acting zone valves.

Sequence, Section B