tekmar 362 Mixing Control Installation User Manual

Page 14

14 of 36

Copyright © D 362 -

12/08

Pointer On

Boil MIN

Boil Wat

er Te

mpe

ratu

re

Boil Min + 1/2 Boiler Differential

Boil Min - 1/2 Boiler Differential

Boil Max + 1/2 Boiler Differential

Boil Max - 1/2 Boiler Differential

Boil W

ate

r Te

mp

era

tur

e

Pointer On

Pointer On

Boil MAX

Sequence, Section D1

DIFFERENTIAL

Mode 1: Heating (Boil DIFF)

When operating in Mode 1, an on / off heat source such as a boiler must be operated with a differential to prevent short cycling. This

differential is centered around the Boil TRG temperature. If the boiler supply temperature drops 1/2 of the differential below the

Boil TRG temperature, the 362 closes the boiler contact to fire the boiler. If the boiler supply temperature rises 1/2 of the differential

above the Boil TRG temperature, the 362 opens the boiler contact to turn off the boiler. With the 362, either a fixed or automatic

differential setting is selected. If the AUTO differential is selected, the 362 automatically adjusts the boiler differential setting under

the current load conditions to avoid short cycling.

Mode 2: Snow Melting (DIFF)

When operating in Mode 2 with the boiler sensor on the boiler supply, it is necessary to set a differential for the boiler. This differential

is centered around the MIX TRG temperature. If the mixing supply temperature drops 1/2 of the differential below the MIX TRG

temperature, the 362 closes the boiler contact to fire the boiler. If the mixing supply temperature rises 1/2 of the differential above the

MIX TRG temperature, the 362 opens the boiler contact to turn off the boiler.

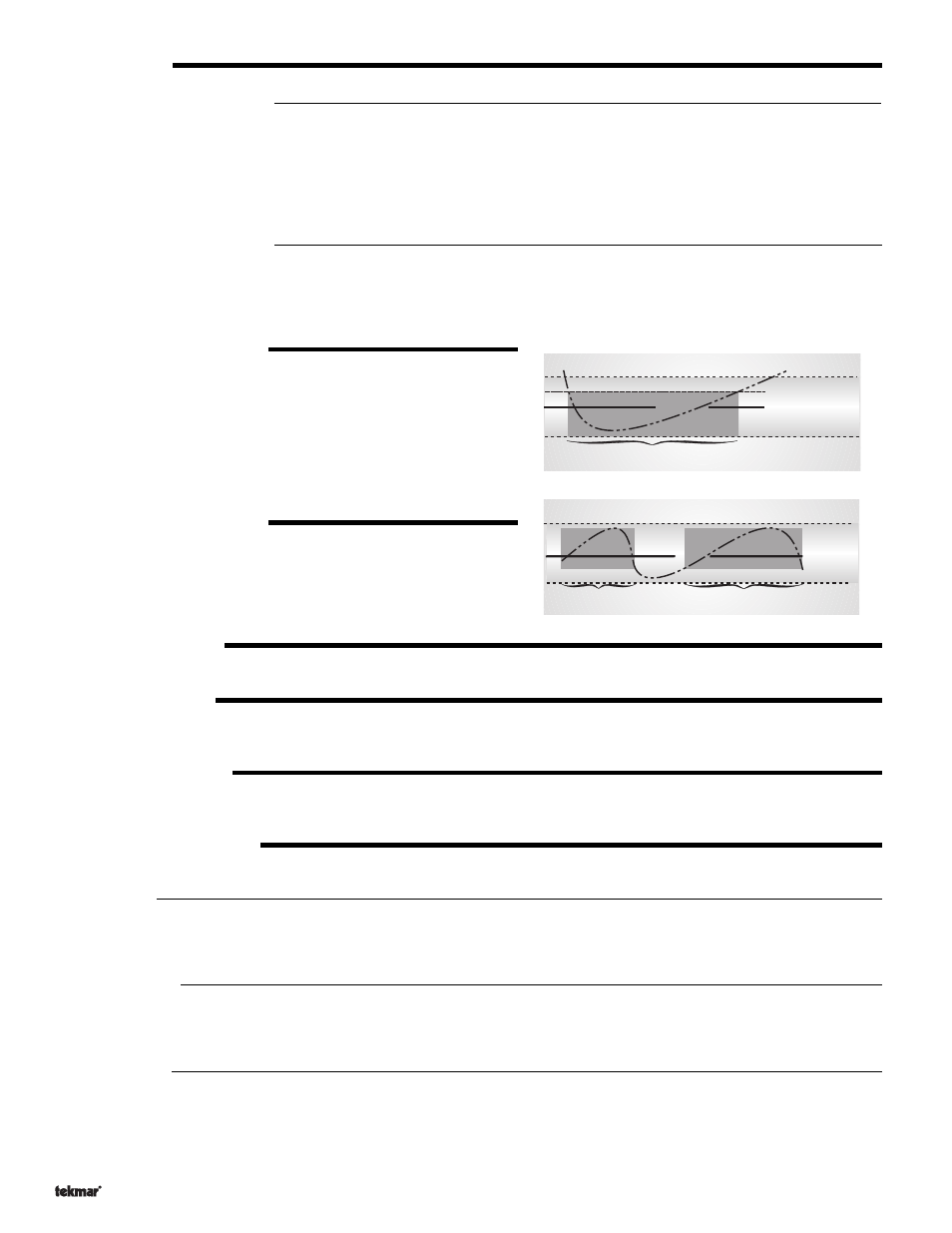

BOILER MINIMUM (Boil MIN)

The Boil MIN is the lowest water temperature that the control is allowed to

use as a Boil TRG

temperature. During mild conditions, if the 362 calculates

a Boil TRG

temperature that is below the

Boil MIN setting, the Boil TRG

temperature is adjusted to at least the Boil MIN setting. During this

condition, if the boiler is operating, the

Minimum pointer turns on in the LCD

while the Boil TRG

or the Boil SUP temperature is viewed. If the installed

boiler is designed for condensing operation, set the Boil MIN adjustment

to OFF.

BOILER MAXIMUM (Boil MAX)

The Boil MAX is the highest water temperature that the control is allowed

to use as a Boil TRG temperature. If the control does target Boil MAX, and

the Boil SUP temperature is near the Boil MAX temperature, the

Maximum

pointer turns on in the LCD while the Boil TRG or the Boil SUP temperature

is viewed. At no time does the control operate the boiler above 248˚F (120˚C).

BOILER PROTECTION

Refer to section A for a description of boiler protection.

BOILER OPERATION

When the 362 determines that boiler operation is required, the

Boiler contact terminals (6 and 7) close. While the boiler contact is closed,

the burner segment in the LCD is displayed.

FIRE DELAY (FIRE DLY)

The FIRE DLY is the delay time that may happen between the time that the 362 closes the boiler contact and the burner fires. This delay

is usually the result of a burner pre-purge or other forms of time delay built into the burner’s safety circuits.

BOILER MASS (Boil MASS)

The Boil MASS setting allows the 362 to adjust to different types of heat sources depending on their thermal mass.

Light (LITE)

The LITE setting is selected if the boiler that is being used has a low thermal mass. This means that the boiler has a very small water

content and has very little metal in the heat exchanger. A boiler that has a low thermal mass comes up to temperature quite rapidly.

This is typical of many copper fin-tube boilers.

Medium (MED)

The MED setting is selected if the boiler that is being used has a medium thermal mass. This means that the boiler either has a large

water content and a low metal content or a low water content and a high metal content. This is typical of many modern residential

cast iron boilers.

Heavy (HEVY)

The HEVY setting is selected if the boiler that is being used has a high thermal mass. This means that the boiler has both a large water

content and a large metal content. A boiler that has a high thermal mass is relatively slow in coming up to temperature. This is typical

of many commercial cast iron and steel tube boilers.