Sequence of operation, General operation – tekmar 362 Mixing Control Installation User Manual

Page 4

4 of 36

Copyright © D 362 -

12/08

P1

OR

Mixing

P1

OR

Mixing

Sequence of Operation

Section A

General

Page 4 - 5

Section B

Mode 1:

Heating

Page 5 - 9

Section C

Mode 2:

Snow Melting

Page 9 - 13

Section D

Boiler Operation

Page 13 - 15

Section A —General Operation

POWERING UP THE CONTROL

When the Mixing Control 362 is powered up, the control displays the control type number in the LCD for 2 seconds. Next, the software

version is displayed for 2 seconds. Finally, the control enters into the normal operating mode and the LCD defaults to displaying the

current outdoor air temperature.

MODES OF OPERATION

The Mixing Control 362 has two distinct operating modes. The mode of

operation for the control is selected in the Adjust Menu.

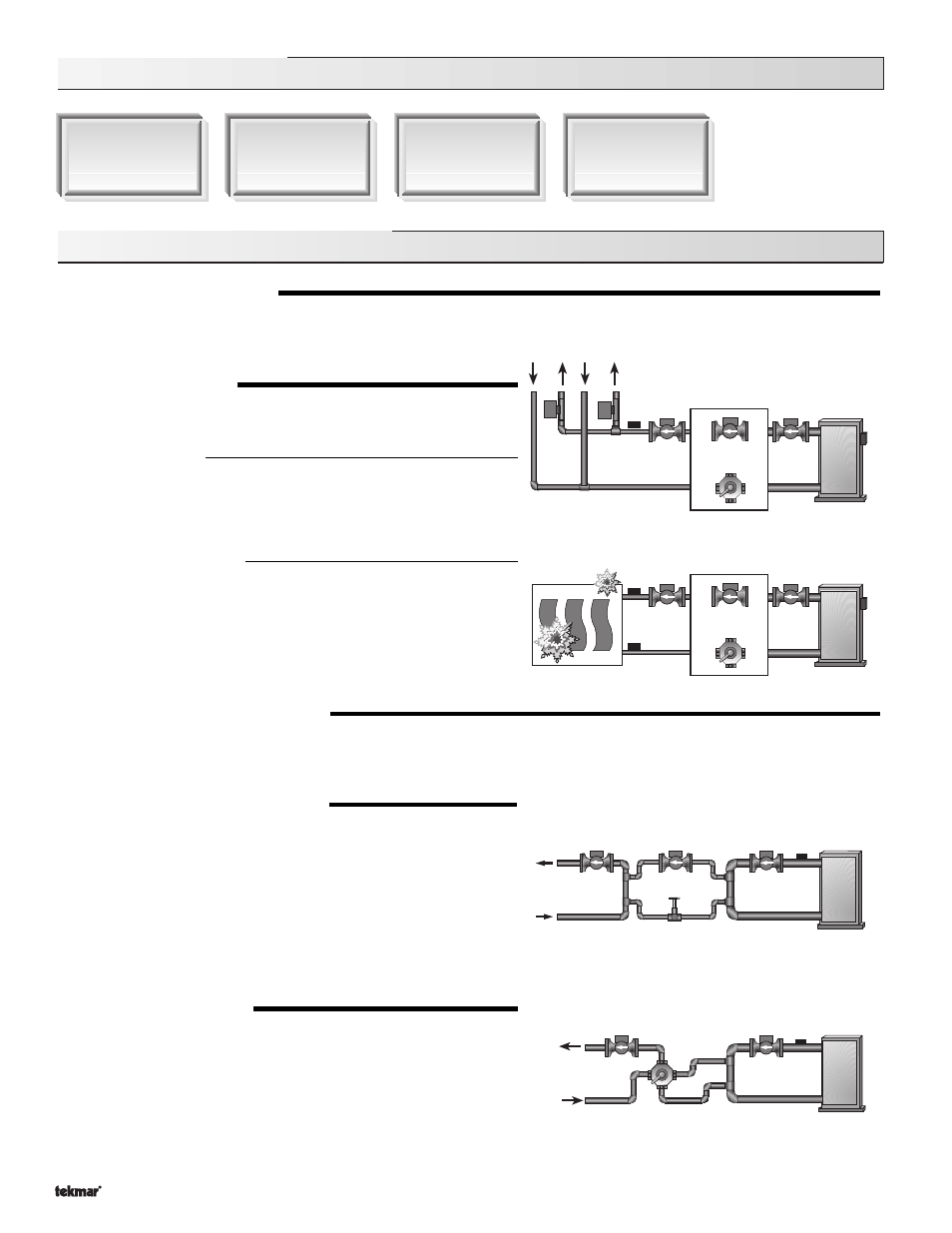

MODE 1 (Heating)

Mode 1 is the Heating mode of operation. In this mode, the 362 is an

Outdoor Reset control for a building heating system. The 362 uses a

mixing device to vary the supply water temperature to the building

heating system according to the outdoor conditions.

MODE 2 (Snow Melting)

Mode 2 is the Snow Melting mode of operation. In this mode, the 362 is

a Slab Outdoor Reset control for a single zone of snow melting. The 362

uses a mixing device to vary the supply water temperature to a single

zone snow melting system. In the Snow Melting mode, the 362 uses a

slab sensor and mixing return sensor in order to provide slab temperature

control and slab protection. It is recommended to purchase a Snow Melt

Enable Kit 092 when using this mode of operation.

MIXING DEVICE SELECTION (MIXING)

The 362 can supply a lower water temperature to part of the heating system by varying the speed of an injection pump or modulating

a mixing valve. This selection is made under the MIXING item in the

Adjust Menu.

VARIABLE SPEED INJECTION (VAR)

A standard wet rotor circulator is connected to the 362 on the

Pwr Mix and

Cls / Var terminals (8 and 10). The 362 increases or decreases the power

output to the circulator when there is a

Mix Demand. The circulator speed

varies to maintain the correct mixed supply water temperature at the mix

sensor. For correct sizing and piping of the variable speed injection driven

circulator, refer to essay E 021. A visual indication of the current variable

speed output is displayed in the LCD in the form of a segmented bar graph.

Two small indicators at the top of the graph indicate whether the output is

increasing or decreasing.

FLOATING ACTION (FLOT)

A floating action actuator motor is connected to the 362 on the

Pwr Mix,

Opn, and Cls / Var terminals (8, 9 and 10). The 362 pulses the actuator

motor open or close to maintain the correct supply water temperature at the

mix sensor when there is a

Mix Demand. The mixing valve that the actuator

is connected to can be either a 2-way, 3-way or 4-way valve. A visual

indication as to whether the control is currently opening or closing the

mixing valve is displayed in the LCD with the words Open and Close. Also,

a visual indication of the current position of the valve is displayed in the LCD

in the form of a segmented bar graph.