Mixing reset – tekmar 362 Mixing Control Installation User Manual

Page 5

5 of 36

Copyright © D 362 -

12/08

Section B1: General Mixing Operation (Mode —1—)

1

2

Mix

Demand

24 to 240 V (ac)

Section B2

Alternate Mixing

Demands

Section B1

General Mixing

Operation

MIX MAX

Mixed Su

pp

ly

W

ate

r Temper

atu

re

Pointer On

Pointer On

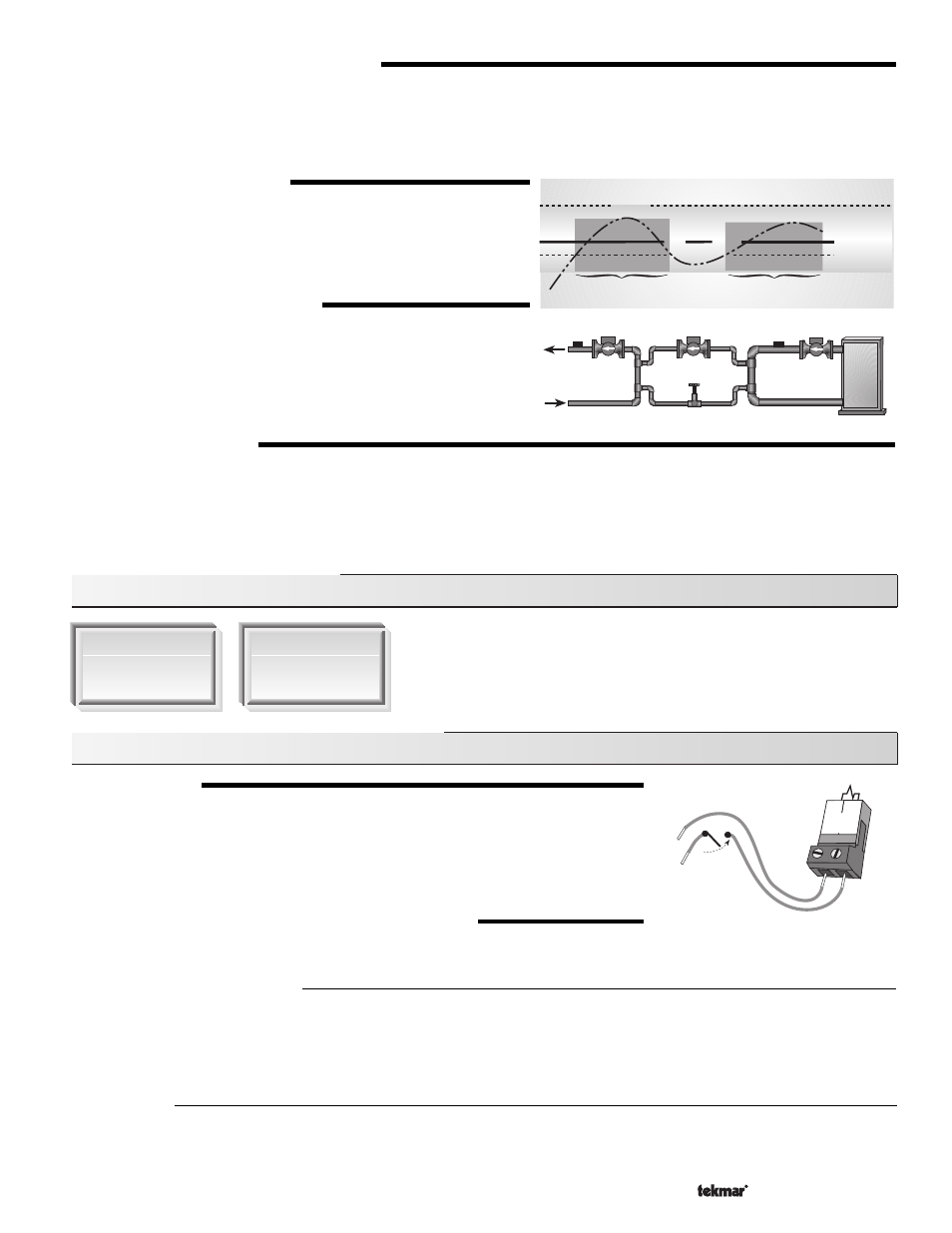

Section B: Mixing Reset (Mode —1—)

MIXING TARGET TEMPERATURE (MIX TRG)

(

RESET

RATIO

&

CHARACTERIZED

HEATING

CURVE

)

When in Mode 1, the MIX TRG temperature is determined from either the

Characterized Heating Curve or the Reset Ratio settings and

the outdoor air temperature. When in Mode 2, the MIX TRG temperature is determined from either the outdoor air temperature and the

desired slab temperature or the Melting and Idling settings. The control displays the temperature that it is currently trying to maintain

as the mixing supply temperature. If the control does not presently have a requirement for heat, it displays “- - -” in the LCD.

MIXING MAXIMUM (MIX MAX)

The MIX MAX sets the highest water temperature that the control is allowed

to calculate as the MIX TRG temperature. If the control does target the MIX

MAX setting, and the MIX SUP

temperature is within 5˚F (3˚C) of the MIX

MAX, the

Maximum pointer is displayed in the LCD while either the MIX

TRG temperature or the MIX SUP

temperature is being viewed.

BOILER PROTECTION (BoiL MIN )

The 362 is capable of providing boiler protection from cold mixing system

return water temperatures. If the boiler sensor temperature is cooler than

the Boil MIN setting while the boiler is firing, the 362 reduces the output

from the mixing device. This limits the amount of cool return water to the

boiler and allows the boiler temperature to recover. This feature can only

be used if the Boil SENS item is not set to NONE.

EXERCISING (EXERCISE)

The 362 has a built-in pump and valve exercising function. The exercising period is adjustable and comes factory set at 70 hours. If a

pump or valve output on the control has not been operated at least once during every exercising period, the control turns on the output

for 10 seconds. This minimizes the possibility of a pump or valve seizing during a long period of inactivity. In the case where a mixing

valve is being used as the mixing device, the 362 ensures that the valve operates over its entire range at least once each exercising

period.

Note: The exercising function does not work if power to the control or pumps is disconnected.

MIXING DEMAND

A mixing demand is generated by applying a voltage between 24 and 240 V (ac) across the

Mix Demand terminals (1 and 2). Once voltage is applied, the Mix Demand pointer is displayed

in the LCD. If the 362 is not in WWSD, the 362 closes the

Mix Pmp contact. The Mixing Pump

segment is displayed in the LCD. The 362 calculates a MIX TRG supply temperature based

on the outdoor air temperature and settings. If required, the 362 operates the boiler in order

to provide heat to the mixing device.

CHARACTERIZED HEATING CURVE OR RESET RATIO

When used as a mixing reset control (MODE 1), the 362 has two methods of varying the supply water temperature based on the outdoor

air temperature. The installer can select either a

Characterized Heating Curve or a Reset Ratio.

Characterized Heating Curve

The

Characterized Heating Curve method of controlling the supply water temperature based on outdoor air temperature and optionally

indoor temperature is the most accurate. The control takes into account the type of terminal unit that the system is using. Since different

types of terminal units transfer heat to a space using different proportions of radiation, convection and conduction, the supply water

temperature must be controlled differently. Once the control is told what type of terminal unit is used, the control varies the supply

water temperature according to the type of terminal unit. This improves the control of the air temperature in the building.

Reset Ratio

The

Reset Ratio method of controlling the supply water temperature is based solely on the outdoor air temperature. This method does

not take into account the type of terminal unit that the heating system is using and therefore is not as accurate as a

Characterized Heating Curve.