tekmar 362 Mixing Control Installation User Manual

Page 33

33 of 36

Copyright © D 362 -12/08

r

o

r

r

E

f

o

n

o

i

t

p

i

r

c

s

e

D

d

e

y

a

l

p

s

i

D

r

o

r

r

E

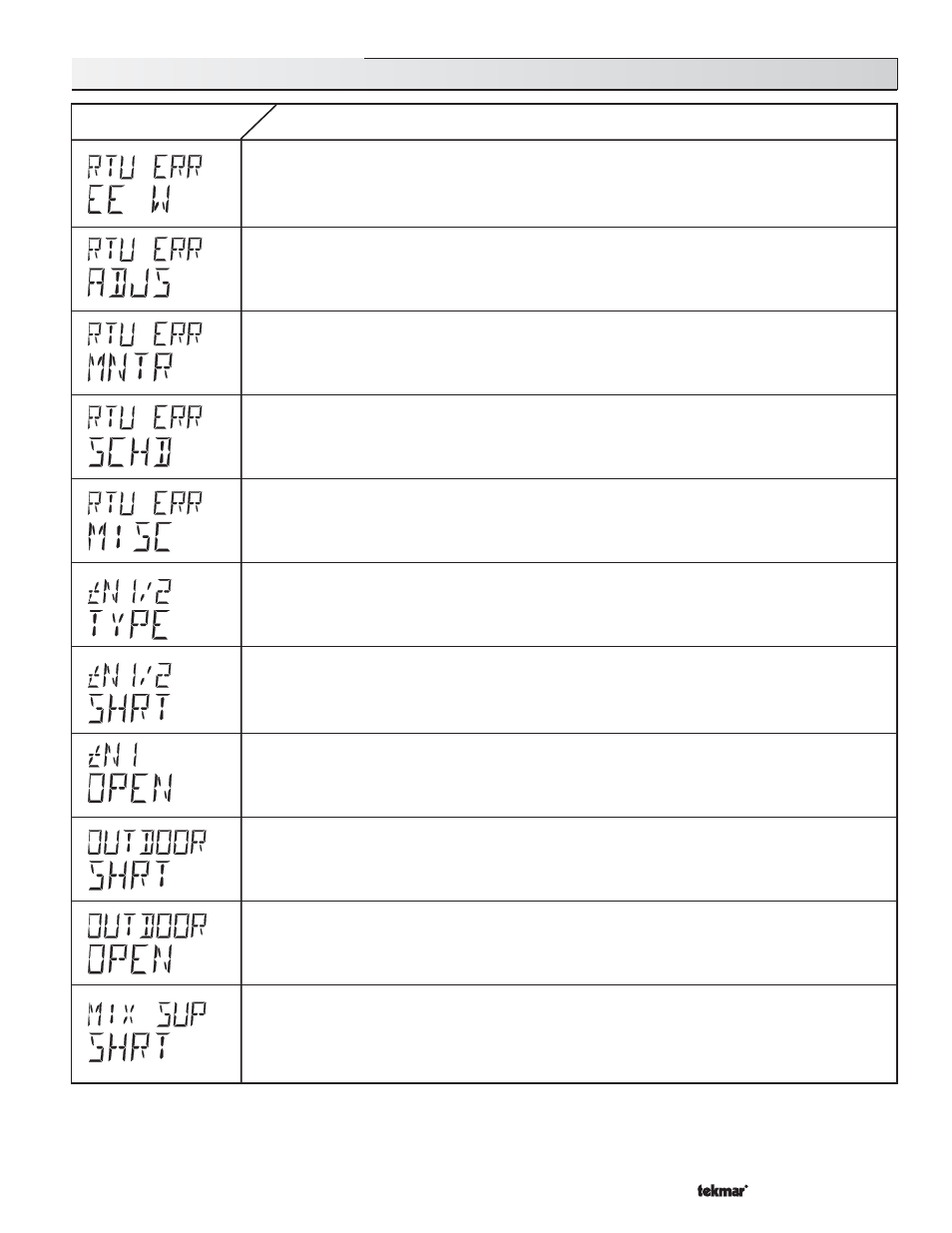

The RTU was unable to read a piece of information stored in the Schedule menu. Because of this,

the control was required to load the factory settings into all of the items in the Schedule menu. The

control will continue to display the error message until all of the items available in the Schedule menu

of the RTU have been checked by the user or installer.

Note: Access level must be ADV in order to

clear the error.

The RTU was unable to read a piece of information stored in the Monitor menu. Because of this, the

control was required to load the factory settings into all of the items in the Monitor menu. The control

will continue to display the error message until all of the items available in the Monitor menu of the

RTU have been checked by the user or installer.

Note: Access level must be ADV in order to clear

the error.

The RTU was unable to read a piece of information stored in the Miscellaneous menu. Because of

this, the control was required to load the factory settings into all of the items in the Miscellaneous

menu. The control will continue to display the error message until all of the items available in the

Miscellaneous menu of the RTU have been checked by the user or installer.

Note: Access level must

be ADV in order to clear the error.

An incorrect device has been connected to the tekmar Net

TM

tN1/tN2 input terminal. An RTU has

been connected to the control and either the

Heating Curve/Reset Ratio DIP switch has been set to

Reset Ratio or the control is in MODE —2—. Once the problem has been corrected, press either the

Menu or Item button to clear the error message from the control.

The RTU was unable to read a piece of information stored in the Adjust menu. Because of this, the

control was required to load the factory settings into all of the items in the Adjust menu. The control

will operate based on only the

Characterized Heating Curve settings until all of the items available

in the Adjust menu of the RTU have been checked by the user or installer.

Note: Access level must

be ADV in order to clear the error.

The RTU was unable to store a piece of information to the EEPROM. This error can be caused by a

noisy power source to the control. The control will display the error message and will continue to

operate as normal. To clear this error, press either the Menu or Item buttons.

The control is no longer able to read the information that is coming from the RTU. Reconnect the RTU

and press either the Menu or Item button to clear the error. If the RTU has been deliberately disconnected

from the control, remove power from the control for 10 seconds and then re-power the control in order

to clear the error message.

A short circuit has been read between the tN1/tN2 terminal and a Com terminal on the control. Either

the wires leading to the tN1/tN2 device are shorted or the polarity of the wires is reversed. Determine

the cause and remove the short. To clear this error, press either the Menu or Item buttons.

The control is no longer able to read the Outdoor sensor due to a short circuit. In this case the control

assumes an outdoor temperature of 32˚F (0˚C) and continues operation. Locate and repair the problem

as described in the Data Brochure D070. To clear the error message from the control after the sensor

has been repaired, press either the Menu or Item button.

The control is no longer able to read the Outdoor sensor due to an open circuit. In this case the control

assumes an outdoor temperature of 32˚F (0˚C) and continues operation. Locate and repair the problem

as described in the Data Brochure D070. To clear the error message from the control after the sensor

has been repaired, press either the Menu or Item button.

The control is no longer able to read the Mixing Supply sensor due to a short circuit. In this case, if

the Boil SENS item is set to SUP, the control will operate the mixing device at a fixed 15% of output

as long as there is a Mixing Demand. If the Boil SENS item is set to RET or NONE, the control operates

the mixing device at a fixed 30% of output as long as there is a mixing demand. Locate and repair the

problem as described in the Data Brochure D070. To clear the error message from the control after

the sensor has been repaired, press either the Menu or Item button.

362 Error Messages (2 of 4)