tekmar 362 Mixing Control Installation User Manual

Data brochure, D 362, Mixing control 362

1 of 36

Copyright © D 362 -12/08

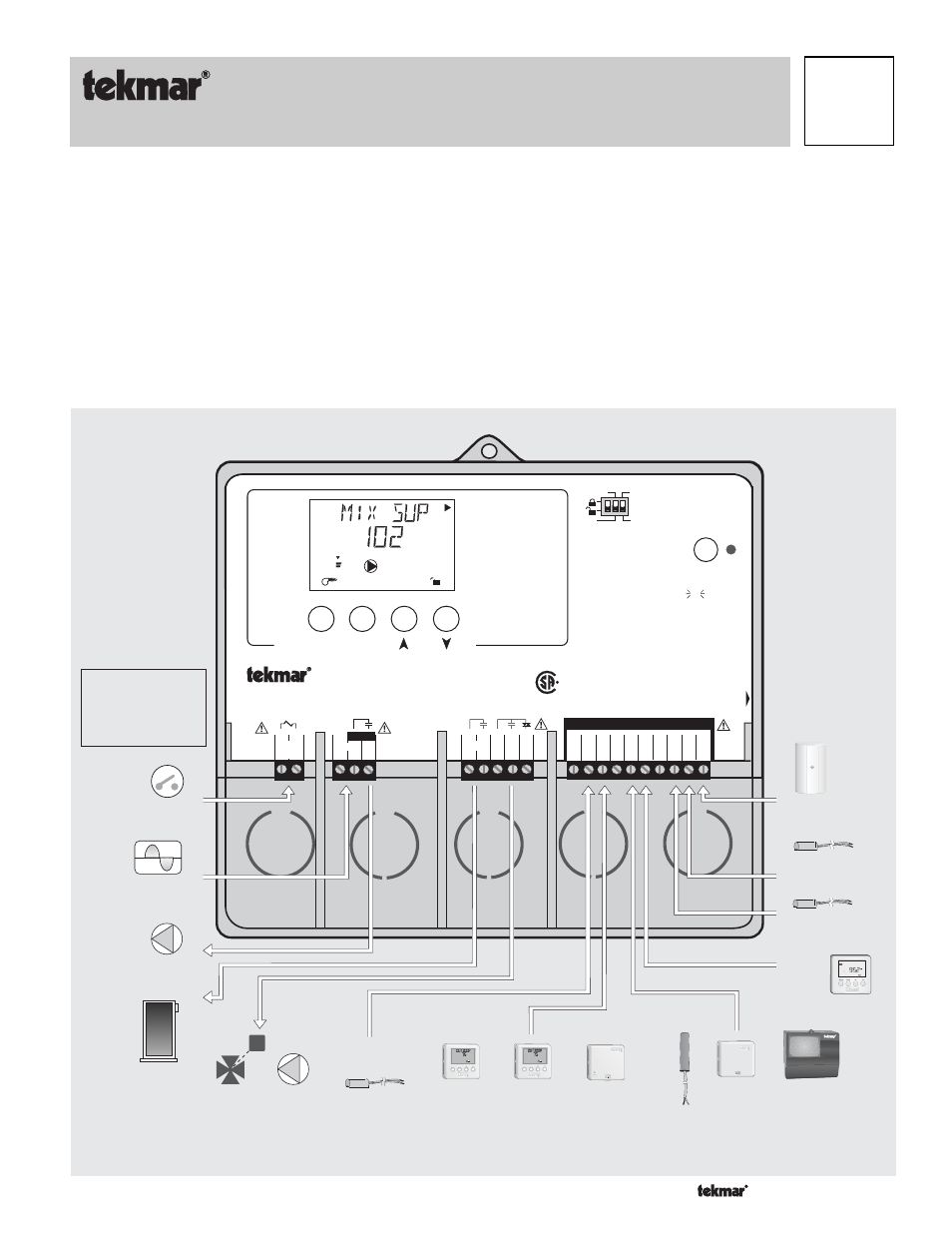

The Mixing Control 362 is a microprocessor based control with two distinct operating modes.

MODE —1— allows the control to provide a reset mixed supply water temperature to a heating system based on outdoor air temperature.

Multiple zone temperature controls can be achieved by using either a conventional thermostat system or by using tekmar Zone Controls

attached to the 362. For single zone heating applications, a single Room Temperature Unit (RTU) can be connected directly to the 362

for zone temperature control.

MODE —2— allows the control to provide a single zone of snow melting. With the addition of a Snow Melting Kit 092, the 362 can

provide slab temperature control and slab ΔT protection. The melting mode is initiated manually either with a demand signal or from the

Snow Melting Kit enabling device.

The 362 incorporates a large Liquid Crystal Display (LCD) in order to provide system status and operating information. The same LCD

is used when setting up and installing the control. Standard features for both modes of operation include boiler return protection,

intelligent boiler operation, Warm Weather Shut Down (WWSD), and pump exercising. As well, with the addition of a new Monitor

feature, it is now possible to track pump and boiler running hours, boiler cycles and high and low sensor temperatures. The 362 also has

a unique feature that allows the control to supply heat to the mixed system from either the boiler or a thermal storage tank.

not testing

testing

off

red

LR 58233 E150539

70

Input

tekmar Slab Sensor or Indoor Sensor or

Zone Control

OR

OR

Input

tekmar

Timer

UnOcc

°F

View

Open

Operating Modes

1 Heating

2 Snow melting

4

Test

not testing

testing

off

red

2

5

Mix

Pmp

7

Pwr

Mix

9

13

tN1/

tN2

14

Com

15

10K

16

UnO

Sw

17

Com

Mixing Control 362

Floating Action / Variable Speed

3

6

8

10

Boiler

Opn Cls

Var

Mix Demand

WWSD

Minimum

Maximum

Melting

Idling

11 12

Com Mix

Ret

Mix

19

Boil

20

Out

18

Mix

Demand

Reset Ratio

Setback

Characterized

Heating Curve

None

Do not apply power

Menu

Item

Power

N L

R

C US

1

%

For maximum heat,

press and hold

Test

button for 3 seconds.

Output

M

Output

Mixing Valve & Actuating

Motor OR Var. Speed

Driven Pump

OR

Input

Universal

Input

Room

Temperature

Unit (RTU)

Input

Remote

Display

Module (RDM)

OR

OR

Input

Snowmelt

Kit

(SMK)

8

7

9

Item

Menu

°F

View

!

WWSD

1

%

%

2

Item

Menu

°F

View

!

WWSD

1

%

%

2

Input

Universal

Sensor

Included

Input

Universal

Input

Outdoor

Output

Mixing System

Pump

Input

120 V (ac) Power

Supply

Input

Mix Demand

Signal

D 362

12/08

Mixing Control 362

- Data Brochure

Note:

Mixing demand must be

powered with 20 to 260

V (ac) before the mixing

valve is able to open and

the boiler is able to fire.

Made in Canada by

tekmar Control Systems Ltd.

tektra 929-04

Signal wiring must be rated at least 300 V.

Wiring must be rated 194°F (90°C) minimum

Meets Class B:

Canadian ICES

FCC Part 15

Dat

e Code

See product literature

INSTALLATION CATEGORY II

H1176D

1

Power

115 V ±10% 60 Hz 900 VA

Relays

230 V (ac) 7.5 A 1/3 hp, pilot duty 240 VA

Var. Pump

230 V (ac) 2.4 A 1/6 hp, fuse T2.5 A 250V

Demands

20 to 260 V (ac) 2 VA

testing paused

red