Controller configuration – Banner A-GAGE MINI-ARRAY Series User Manual

Page 26

26

P/N 43298 rev. E

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

MINI-ARRAY

®

Instruction Manual

Hysteresis (Low and High) determines how much change must occur at each set

point to cause the associated output to change state. Hysteresis avoids unstable

output conditions (e.g., chattering of the output) when the scanning condition exactly

matches one of the set points. The default setting for hysteresis is one beam less than

the Low Set Point and one beam more than the High Set Point.

Scan # is the number of consecutive scans of the array required before the associated

output is updated. The controller can be programmed for from one to nine consecutive

scans. The scan data MUST BE THE SAME for all consecutive scans for the outputs to

be updated.

Invert (Y/N) allows the output to be normally open (No) or normally closed (Yes).

Models MAC16P-1, MAC16N-1 — Discrete Outputs

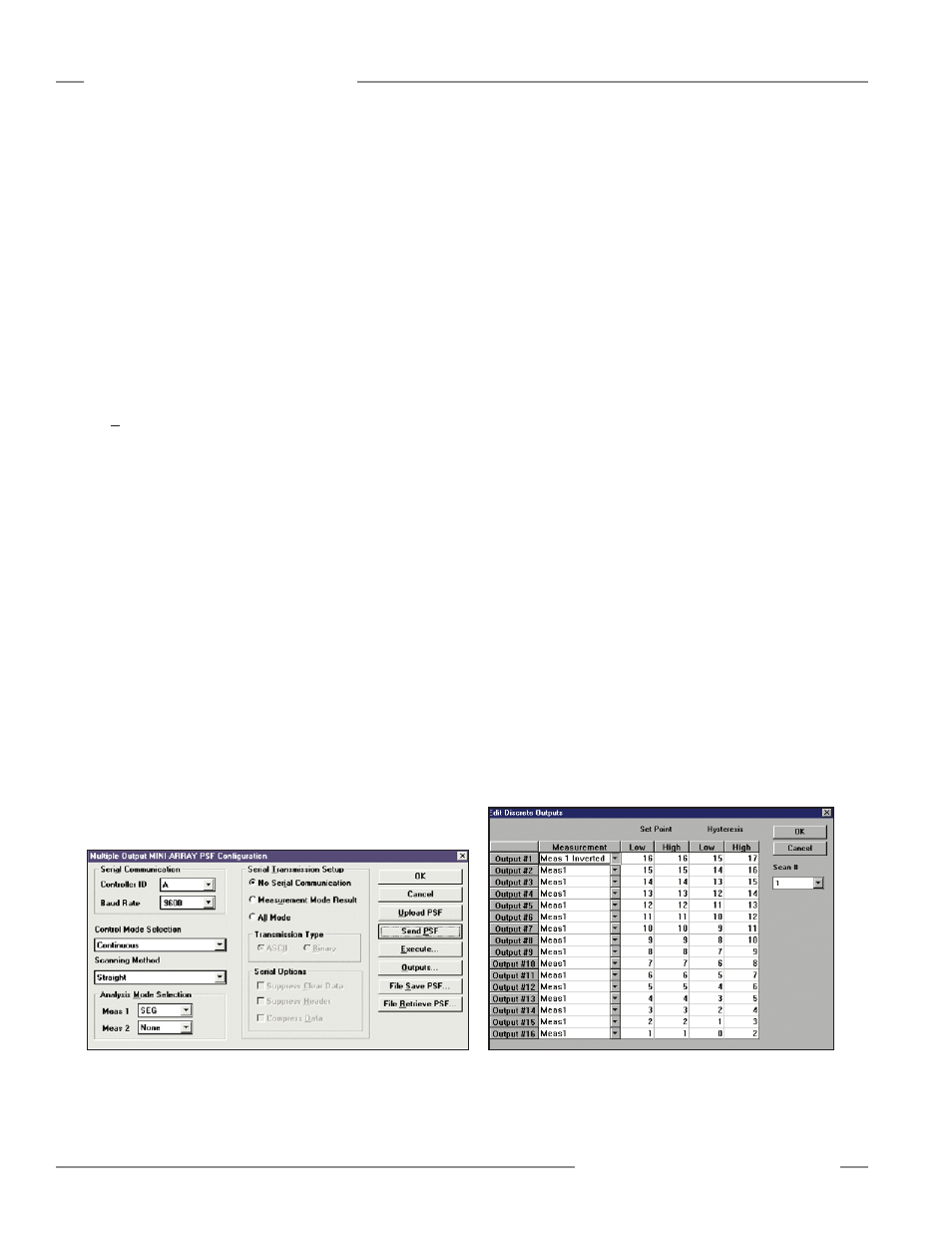

The sixteen discrete outputs are programmed using the Outputs button on the Multiple

Output MINI-ARRAY PSF Configuration screen (Figure 5-10).

The Outputs Button launches the Edit Discrete Outputs screen (Figure 5-11, which

allows the Set Points and Hysteresis levels to be defined for each output. Set Point

and Hysteresis values may be configured individually for each output and assigned

to either Meas1 or Meas2. Set Point level defines the condition where the output is

in the “true condition”. For a typical application, the output will be active when the

Measurement mode result is between the set point limits. If the inverted option is

specified, the output will be inactive when the Measurement mode result is between

the set point limits (i.e., the true condition). The Hysteresis Low and High levels

determine when the output will change back to the false condition.

The SEG measurement mode uses the Set Point Low and High levels to define

segmentation of the light screen. As an example, Output #1 Set Point Low is 5 and

the Set Point High is 20. These two values define beams 5 through 20 as a segment.

Whenever any of these beams are blocked, this segment of the light screen is

considered blocked, and Output #1 will be active (or inactive, if “Inverted” is selected).

For the SEG measurement mode, the Hysteresis specification is inactive. The Scan

Number may be used to change the number of consecutive scans necessary to change

the output. When the Scan Number is set to one, the output will change after only

one scan. If the Scan Number is set to five, the outputs will not change unless the

condition is true for five consecutive scans.

Figure 5-10. PSF Configuration screen (models MAC16P-1 and

MAC16N-1)

Figure 5-11. Edit Discrete Outputs screen

Controller Configuration