Installation and mechanical alignment, 1 emitter and receiver mounting, Mini-array – Banner A-GAGE MINI-ARRAY Series User Manual

Page 13

P/N 43298 rev. E

13

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

MINI-ARRAY

®

Instruction Manual

Installation and Mechanical Alignment

3.1 Emitter and Receiver Mounting

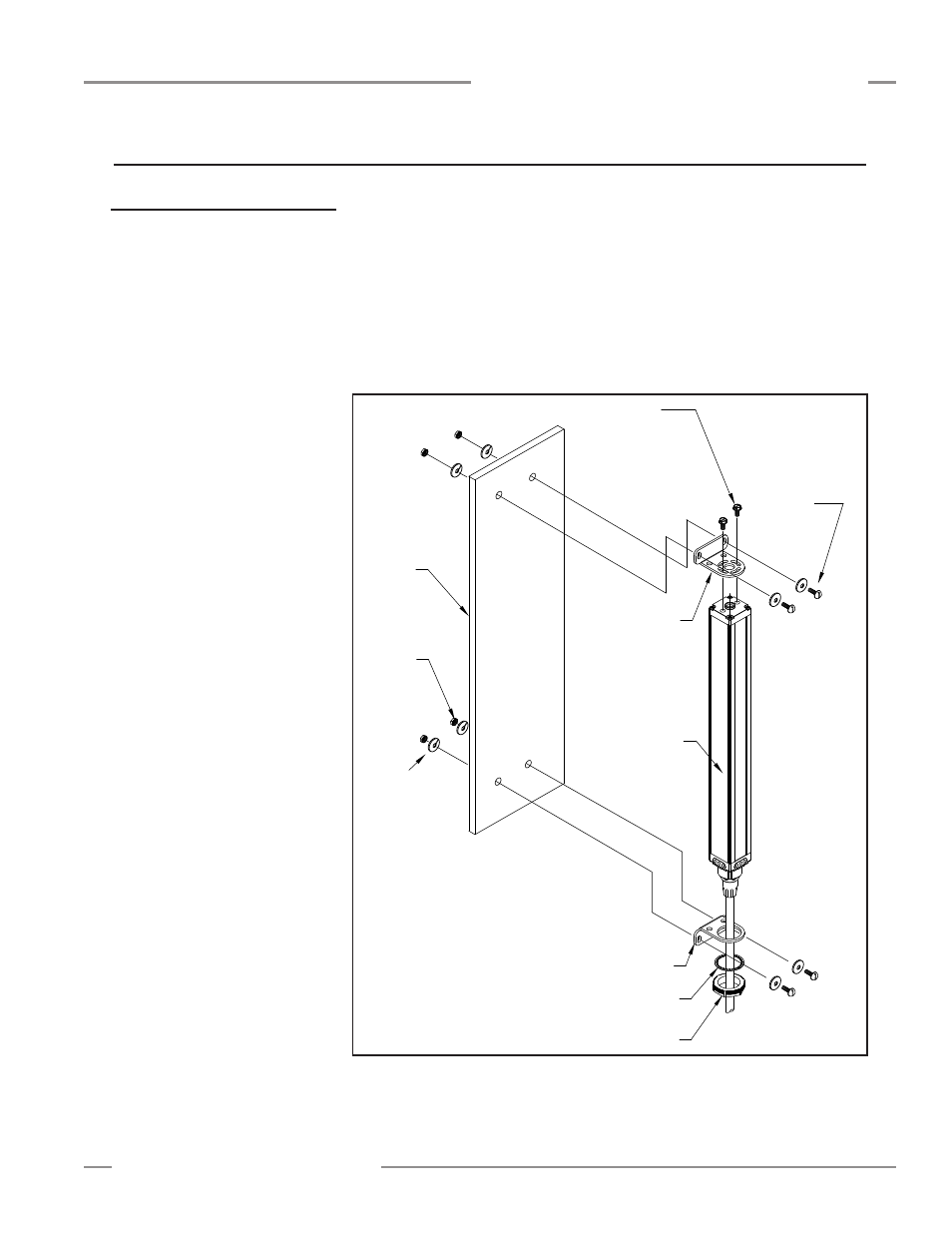

Banner MINI-ARRAY emitters and receivers are small, lightweight, and easy to mount; the mounting brackets (supplied) allow ±30

degrees rotation.

From a common point of reference, make measurements to position the emitter and receiver in the same plane with their

midpoints directly opposite each other. Mount the emitter and receiver brackets using the M4 x 0.7 x 14 mm bolts and associated

mounting hardware (all supplied). See Figure 3-1.

Although the internal circuitry of the emitter and receiver can withstand heavy impulse forces, vibration isolators can be used

instead of the M4 bolts to dampen impulse forces and prevent possible damage from resonant vibration of the emitter or receiver

assembly. Two different Anti-Vibration Mounting Kits are available from Banner as accessories.

Figure 3-1. MINI-ARRAY emitter and receiver mounting hardware

Emitter

or

Receiver

Mounting

Mounting

Bracket

Surface

M4

Nut (4)

Washer (2)

with Compression

Slotted Hex Head

M4 x 10 mm

Bracket

Mounting

Nut

Washer

M4 x 14 mm

Screw with Flat

Washer

Compression

Washer (4)

Torque to

12 in. lbs.

(1.3 N-m)

3. Installation and Mechanical Alignment

P/N 48955 consists of 4 anti-vibration

mounts (M4 x 0.7 x 9.5 mm) and 8

M4 Keps nuts. These mounts are made

from BUNA-N rubber and are more

resistant to chemicals and oils.

P/N 12847 consists of 4 anti-vibration

mounts (M4 x 0.7 x 9.5 mm) and 8

M4 Keps nuts. These mounts are made

from natural rubber, which are less

chemically resistant than the 48955

mounts, but have a greater sheer force

spec at higher temperature.