Metrohm NIRS XDS RapidLiquid Analyzer User Manual

Page 8

6

▪▪▪▪▪▪▪

Green when stable operating temperature is reached

Green when module is properly attached

Vision Software™ offers an easy user interface, using the familiar interface provided with previous

generations of NIR instrumentation. All functions required to perform identification, qualification, and

quantitation are provided, with easy tools for interpretation of results. Vision offers full instrument

diagnostics, with built-in acceptance specification tables for all tests. Vision stores all results in a

diagnostic database for later lookup, with control chart views of results tracked over time.

The menu-driven, validated Vision Software package meets all requirements of CFR 21 Part 11,

covering Electronic Records and Signatures. Vision comes with a full manual for operation and theory

of operation, with complete instructions for analytical development.

The XDS Analyzer provides 0.5nm data points, and uses several innovative methods to assure

wavelength accuracy and repeatability. Wavelength positions are traceable to NIST SRM-2035. The

XDS Liquid Analyzer uses a three-layer calibration standard, measured against SRM-2035, to provide

stable, repeatable wavelength settings. Use of this standard for Instrument Calibration enhances

calibration transfer between instruments.

Instrument communication is through RJ-45 network connections, which eliminates issues involved

with long runs of RS-232 cable. An Internet Protocol (IP) address is dynamically requested upon

connection. This address may be permanently installed, if required for network purposes. The RJ-45

connection also permits remote interrogation and diagnostics checks of the instrument, if necessary

and authorized.

The instrument enclosure is completely sealed to prevent contamination by dust or other substances.

The cooling fans operate outside the main enclosure, and are thermally linked to internal fans that

maintain a constant temperature inside the instrument enclosure. There is no airflow drawn into the

optics chamber of the instrument. This avoids contamination of the instrument in dusty

environments. An air filter is built into the door of this chamber. For cool environments, heaters are

embedded in the thermal transfer block to raise temperature when required.

Lamp changes are performed through a single panel on the rear surface of the instrument. The lamp

is easy to remove and replace, and requires no special tools or expertise.

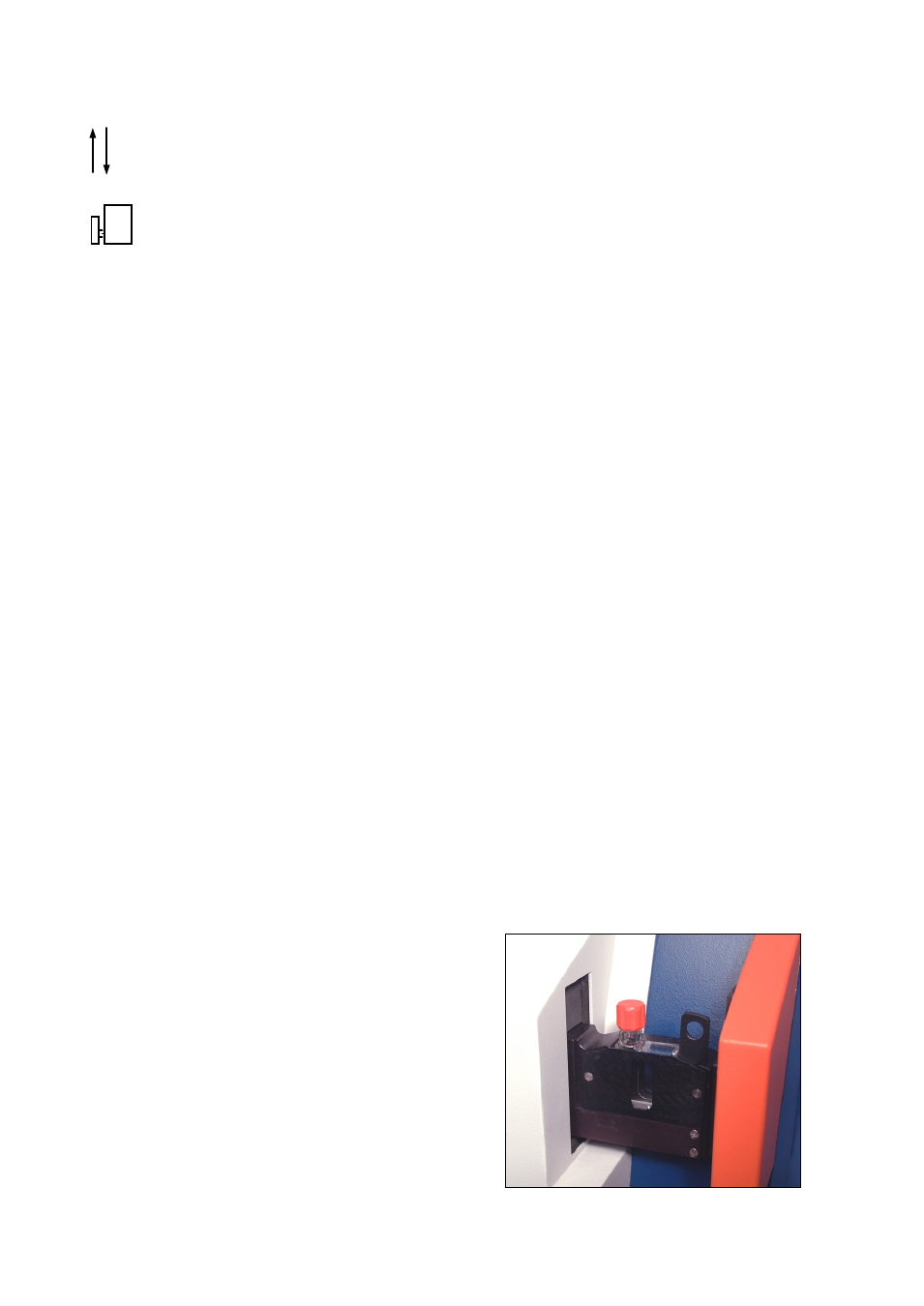

The Metrohm Rapid Liquid Analyzer is available with a

variety of quartz cuvettes to make analysis

straightforward and easy. A sealable cuvette, suitable

for volatile liquids is shown.

Capped cuvettes and other styles are available, in

various path lengths. Select path length based upon

absorbance of the analytes of interest.

See section 5.0 for full information.