5 rapid liquid module, 2 blank correction, Rapid liquid module – Metrohm NIRS XDS RapidLiquid Analyzer User Manual

Page 27: Blank correction, 5rapid liquid module

▪▪▪▪▪▪▪

25

5

Rapid Liquid Module

The XDS™ Rapid Liquid Analyzer is designed for sampling of many types of customer samples. This

section describes initial calibration steps, which are detailed in section 7.1. This section gives a

functional overview, so the operation can be anticipated and understood.

5.1

Wavelength Calibration of the Rapid Liquid Analyzer

The Rapid Liquid Analyzer uses an innovative method of

wavelength calibration, to assure consistency between like

instruments. A wavelength standard, using materials with

known, stable peak positions, is used to calibrate the

wavelength scale of each instrument.

This wavelength standard is calibrated on a controlled

master instrument, and is characterized against SRM-

2035, a National Institutes of Standards and Technology

(NIST) transmission standard. This assures that wavelength

registration of each Liquid Analyzer is set to known

standards.

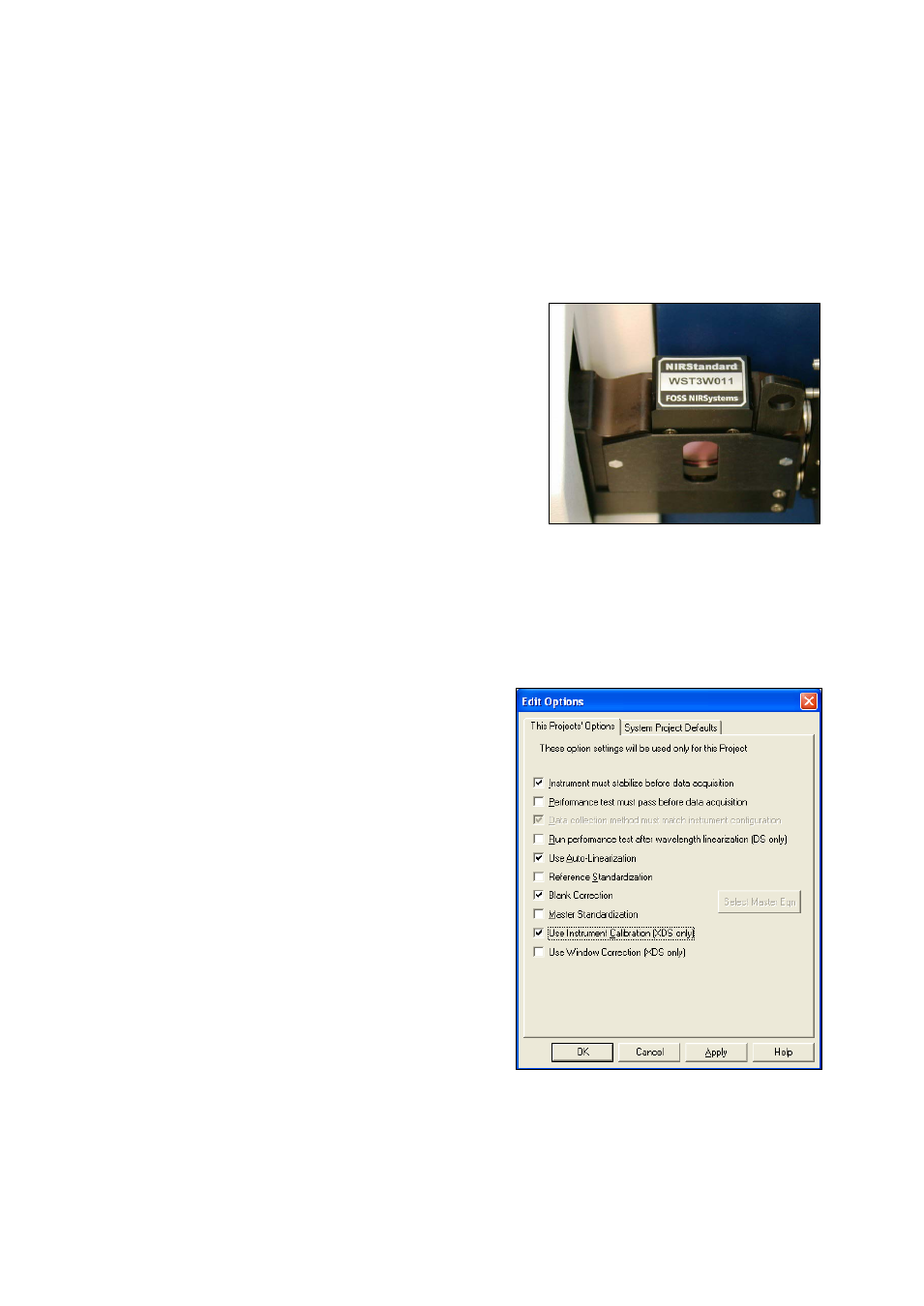

Instrument Calibration is required for transferability between instruments. It is activated under

Configure, Project Options in Vision Software. This feature is fully explained in section 7.1.3.

5.2

Blank Correction

The Rapid Liquid Analyzer has the option of “Blank

Correction” to provide an optimum photometric

match between instruments. Vision takes a spectral

scan of the sampling area (with spacer inserted), then

a spectral scan of the reference path. A correction

algorithm is applied to eliminate the slight difference

between sample and reference.

Blank Correction must be selected in Configure,

Project Options, in the screen shown at right.

A software algorithm applies the correction to each

spectrum automatically. This selection feature is fully

explained in section 7.1. Blank Correction is explained

in section 7.1.3.